Intermittent type rapid-cooling crystallizing assisting tank

A rapid cooling and intermittent technology, applied in the direction of heat exchange cooling crystallization, solution crystallization, crystallization separation, etc., can solve the incompatibility between cooling speed and crystallization speed, large temperature difference between crystallization medium and cooling water, and crystallization scale on the inner cylinder wall Serious and other problems, to achieve the effects of controllable quality stability, shortened crystallization cycle, and short crystallization cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

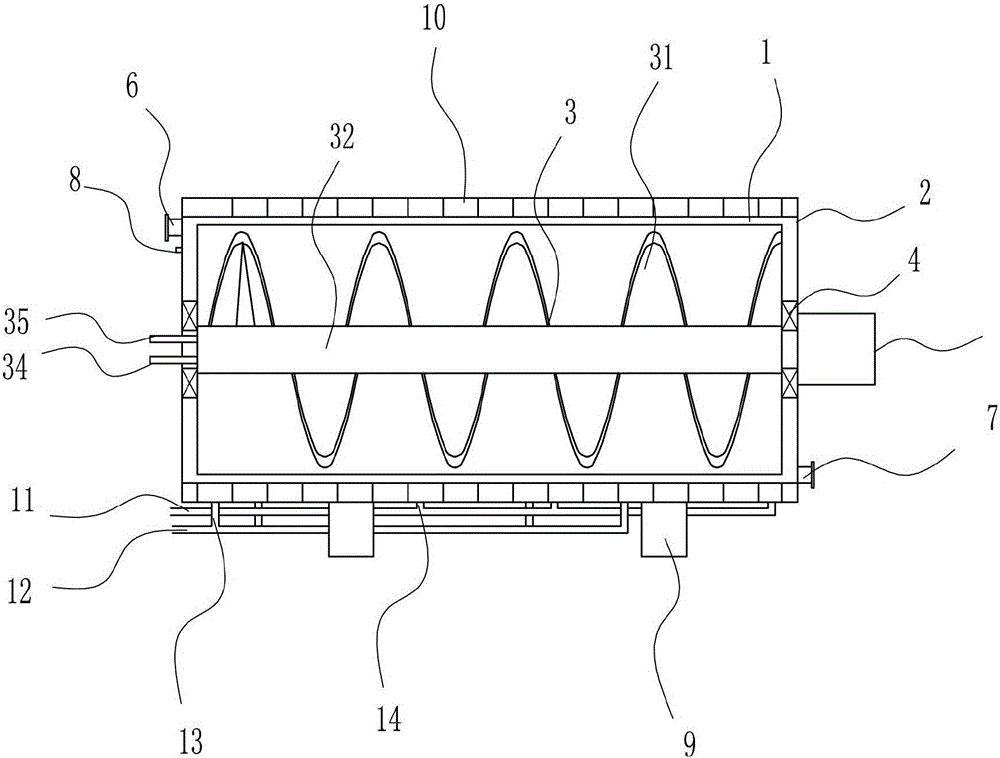

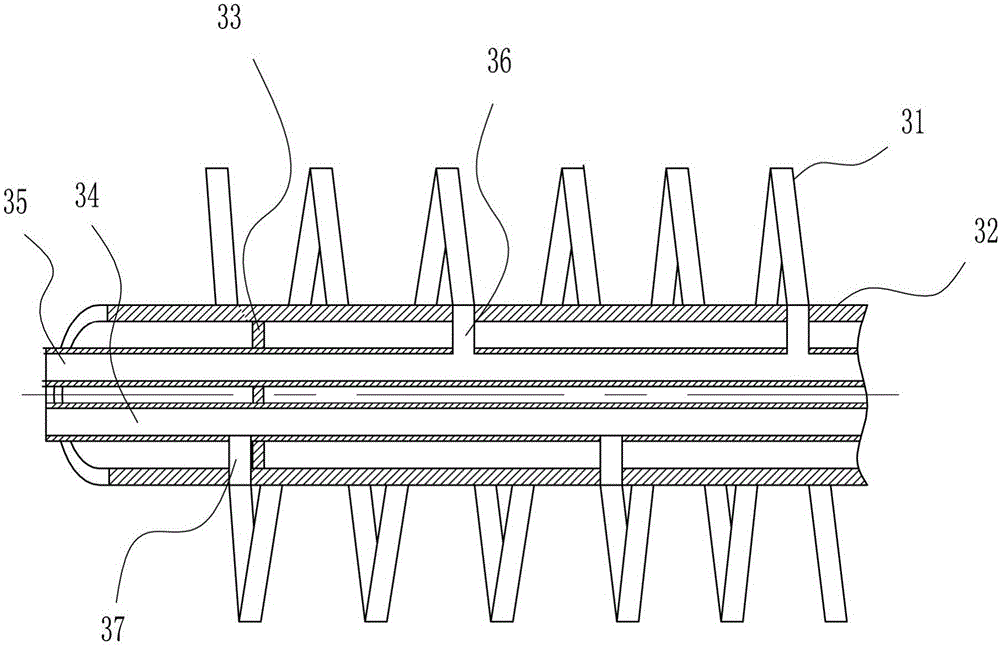

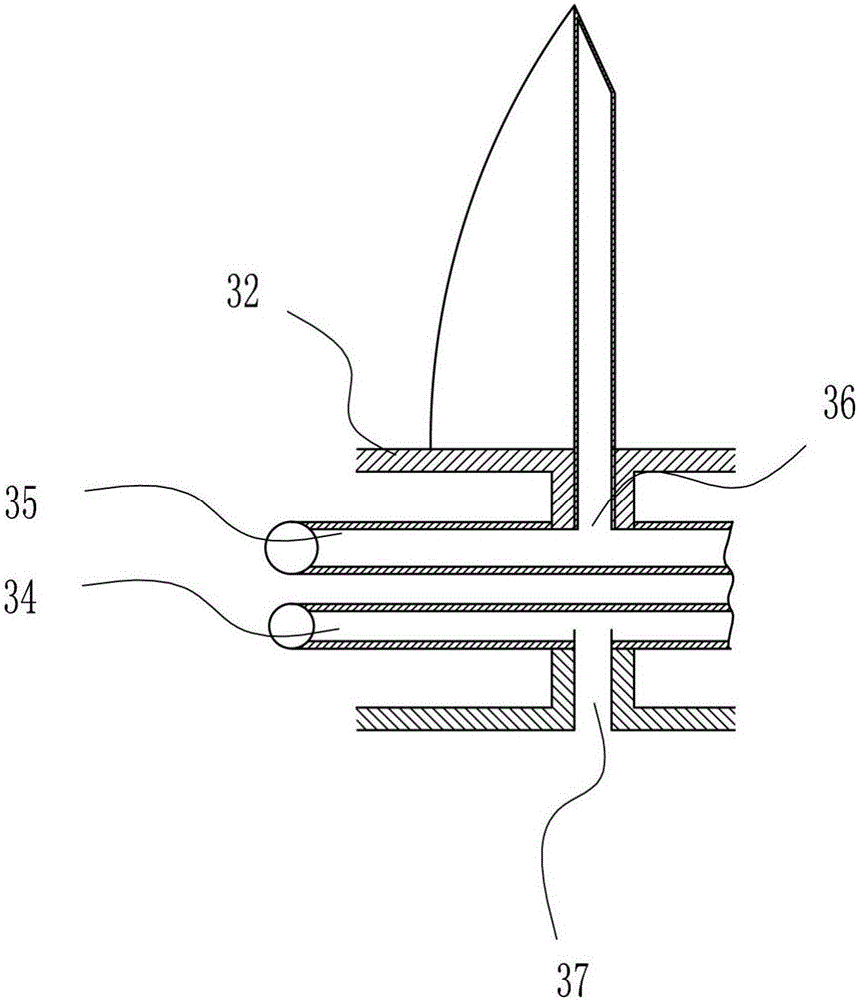

[0035] A kind of intermittent rapid cooling crystal booster tank, such as Figure 1-7As shown, it includes an outer cylinder 1, a W-shaped stirring paddle 3, a bearing 4, a driving device 5, an inlet hopper 6, an outlet 7, an online detection connection port 8, a support 9, a cooling water jacket 10, a second assembly The water inlet pipe 11, the second main water outlet pipe 12, the second water outlet pipe 13 and the second water inlet pipe 14, bearings 4 are fixedly installed on the two end faces 2 of the outer cylinder 1, the W-shaped stirring paddle 3 is erected in the outer cylinder 1, and the W-shaped The stirring paddle 3 includes a W-shaped cavity paddle 31, a hollow shaft 32, a fixed plate 33, a first water outlet pipe 34, a first water inlet pipe 35, a first water inlet pipe 36 and a first water outlet pipe 37, and the hollow shaft 32 Installed on the two end faces 2 of the outer cylinder 1 on the bearings 4, the outer wall on the right side of the outer cylinder 1 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com