A wet porous roller shutter electrostatic precipitator

An electrostatic precipitator and precipitator technology, applied in the direction of external electrostatic separator, electrostatic separation, electrode cleaning, etc., can solve the problems of high cost, corrosion of internal parts, complex structure, etc., and achieve simple structure, high work efficiency, and convenient maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

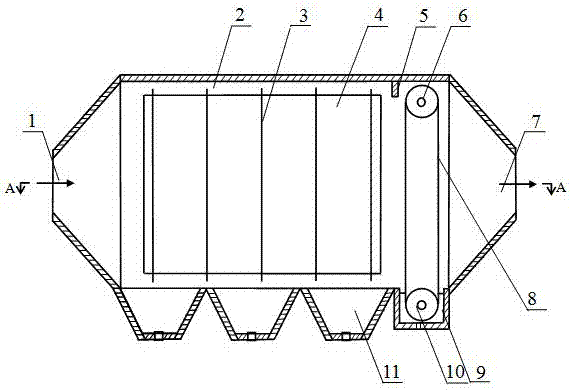

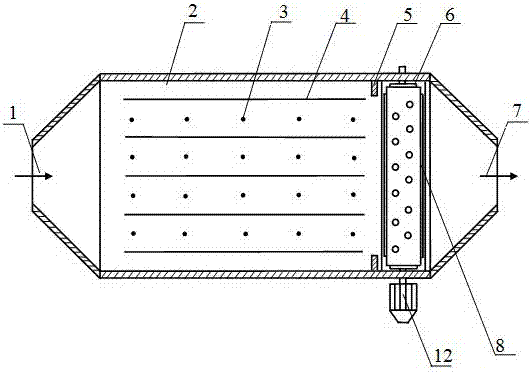

[0023] A wet type porous roller shutter electrostatic precipitator. like figure 1 and figure 2 As shown, the wet-type porous roller shutter electrostatic precipitator is composed of a dry-type electrostatic precipitator, a baffle (5) and a wet-type porous roller shutter dust catcher. The dry electrostatic precipitator is equipped with a wet-type porous roller shutter dust-catching device, one wet-type porous roller-screen dust-catching device is located on the side of the air outlet box (7), and the baffle (5) is located at the intake of the wet-type porous roller shutter dust-catching device. side.

[0024] like figure 1 and figure 2 As shown in the figure, the structure of the dry electrostatic precipitator is as follows: the left and right sides of the precipitator body (2) are correspondingly provided with an air intake box (1) and an air outlet box (7), and the bottom of the precipitator body (2) Three ash hoppers (11) are evenly arranged, the dust collector body (...

Embodiment 2

[0031] A wet type porous roller shutter electrostatic precipitator. Except the following technical parameters, all the other are the same as in Example 1:

[0032] The dry electrostatic precipitator is equipped with two wet-type porous roller shutter dust-catching devices, the two wet-type porous roller-screen dust-catching devices are located on one side of the air outlet box (7), and the two wet-type porous roller shutter dust-catching devices are parallel to each other;

[0033] The bottom of the dust collector body (2) is evenly provided with 2 or 4 ash hoppers (11);

[0034] The width of the front baffle is equal to 1.3~1.5 times the distance between the front side of the wet perforated roller shutter (8) and the front side plate of the main body; the width of the top baffle is equal to 1.3 times the minimum distance between the wet perforated roller blind (8) and the top plate of the main body ~1.5 times;

[0035] The width of the water tank (9) is equal to 1.4~1.5 tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com