Laser impact welding device and laser impact welding method

A laser shock and welding device technology, applied in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problems of reducing welding reliability, affecting welding efficiency, difficult to automate, etc., to achieve high joint surface quality, welding device Simple and efficient welding results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

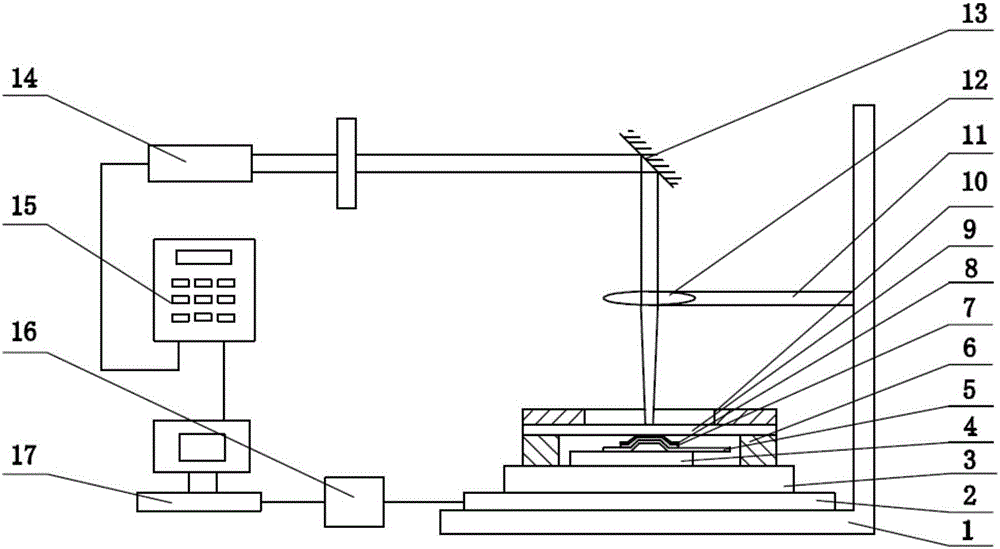

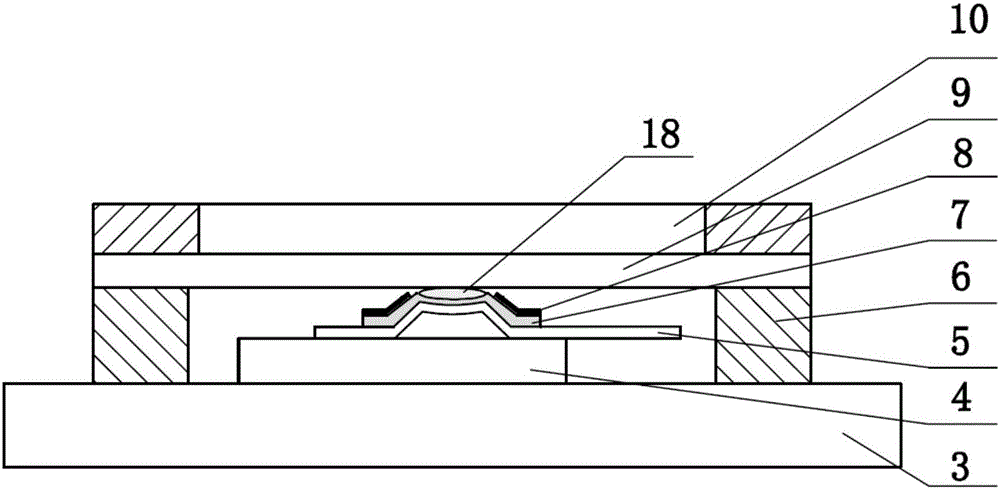

[0033] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto. Such as figure 1 As shown, a laser shock welding device includes a three-coordinate mobile platform device, a laser generating device, a welding device and a control device;

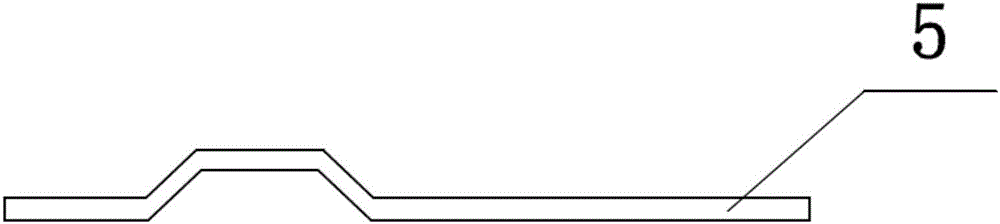

[0034] The three-coordinate mobile platform 2 is located on the bottom plate of the L-shaped base 1, the focusing lens 12 is connected to the focusing lens fixing rod 11, and the focusing lens fixing rod 11 is installed on the side plate of the L-shaped base 1; the pulse laser 14 The emitted laser beam is irradiated on the black paint layer 8 above the inverted trapezoidal step in the upper plate 5 through the reflector 13 and the focusing lens 12 .

[0035] Described laser generating device comprises pulse laser 14, reflecting mirror 13, focusing lens 12, focusing lens fixed rod 11; Paint layer 8, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Pulse width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com