A kind of cutting edge processing technology

A technology for processing technology and knives, which is applied in the field of tool edge processing technology, can solve the problems of rough cutting edge, reduce the wear resistance of the cutting edge, and deep roughness, etc., and achieve the reduction of cutting edge chipping, high durability requirements, The effect of improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of tool edge processing technology described in the present invention, comprises the following steps:

[0030] (a) Process the shape of the tool with a lathe according to the size of the drawing, hold the tool in the left hand, place the tool on the fixed seat so that the cutting edge of the cutting tool is parallel to the horizontal reference line of the fixed base, and process on the cutting edge of the cutting tool at a constant speed with the right hand ;

[0031] (b) Then put the tool processed with the file into the polishing machine for polishing, set the speed of the polishing machine to 45r / s, and set the polishing time to 10 minutes clockwise and 2 minutes counterclockwise;

[0032] (c) Clamp the ultra-fine fluff brush to the wheel brush instrument, set the speed of the wheel brush instrument to 200r / s, and set the time to 1.5 minutes, place the tool on the workbench under the ultra-fine fluff brush for fine polishing , After processing, just remove th...

Embodiment 2

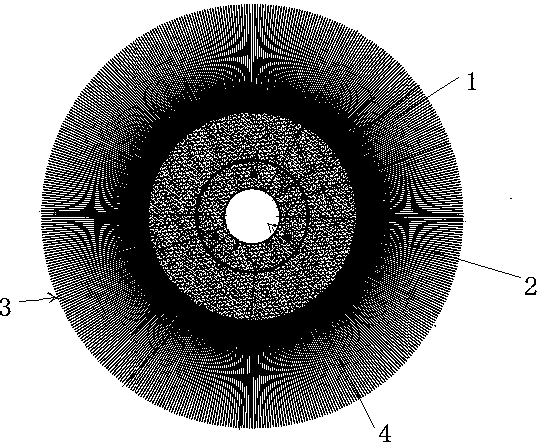

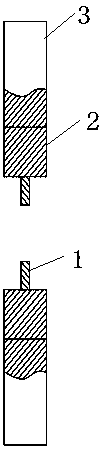

[0042] The ultra-fine fluff brush in step (c) described in this embodiment includes a clamping positioning surface 1, a base body 2,

[0043] Superfine velvet 3, the clamping positioning surface 1 is a ring, the middle position is a clamping matching hole 4, the base 2 is a ring setting outside the clamping positioning surface 1, and the ultrafine velvet 3 is evenly arranged on the base 2 outer edge.

[0044] The material of the superfine fleece 3 in this embodiment is plastic.

[0045] The material of the base 2 in this embodiment is iron.

[0046] In this embodiment, the diameter of the clamping matching hole 4 is 20 mm, the thickness of the clamping positioning surface 1 is 3 mm, the inner diameter of the clamping positioning surface 1 is 20 mm, and the outer diameter is 40 mm.

[0047] In this embodiment, the thicknesses of the substrate 2 and the superfine fleece 3 are the same as 15mm, the inner diameter of the substrate 2 is 40mm, and the outer diameter is 75mm, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com