Diffusion plate cropping process

A diffusion plate and cutting technology, applied in metal processing and other directions, to achieve the effect of improving product quality, improving product qualification rate, and saving hair removal.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

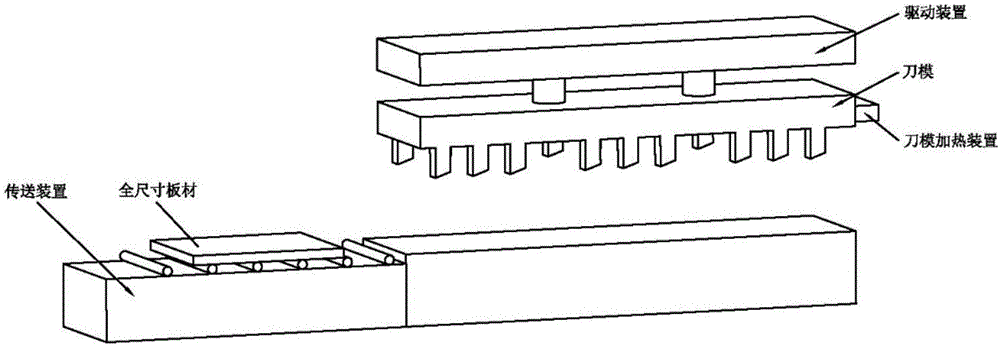

[0036] A diffusion plate cutting process, using a cutting device to cut a full-size diffusion plate plate, the cutting device mainly includes a steel knife wood mold with a blade height of 1mm, an electric heating device for the knife mold, and a hydraulic drive mechanism, The hydraulic drive mechanism drives the cutting and reset of the die cutter, and the cutting process is carried out according to the following steps:

[0037] (1) An installation step, installing the die cutter heating device on the die die;

[0038] (2) heating step, heating the die die to 150 degrees Celsius by the die die heating device, and keeping it;

[0039] (3) In the conveying step, the full-size diffuser plate is conveyed to the cutting die position of the cutting device through the conveying device;

[0040] (4) Cutting step, set the pressure applied by the driving mechanism to the die die to be 10 tons, start the drive mechanism, then advance the die die to cut the full-size diffuser plate, and...

Embodiment 2

[0044] A diffusion plate cutting process, using a cutting device to cut a full-size diffusion plate plate, the cutting device mainly includes a wooden mold with a blade height of 12mm, an electric heating device for the knife mold, and a hydraulic drive mechanism, The hydraulic drive mechanism drives the cutting and reset of the die cutter, and the cutting process is carried out according to the following steps:

[0045] (1) An installation step, installing the die cutter heating device on the die die;

[0046] (2) heating step, heating the die die to 150 degrees Celsius by the die die heating device, and keeping it;

[0047] (3) In the conveying step, the full-size diffuser plate is conveyed to the cutting die position of the cutting device through the conveying device;

[0048] (4) Cutting step, set the pressure applied by the driving mechanism to the die die to be 1000 tons, start the drive mechanism, then advance the die die to cut the full-size diffuser plate, and contac...

Embodiment 3

[0052] A diffusion plate cutting process, using a cutting device to cut a full-size diffusion plate plate, the cutting device mainly includes a wooden mold with a blade height of 6mm, an electric heating device for the knife mold, and a hydraulic drive mechanism. The hydraulic drive mechanism drives the cutting and reset of the die cutter, and the cutting process is carried out according to the following steps:

[0053] (1) An installation step, installing the die cutter heating device on the die die;

[0054] (2) heating step, heating the die die to 90 degrees Celsius by the die die heating device, and keeping it;

[0055] (3) In the conveying step, the full-size diffuser plate is conveyed to the cutting die position of the cutting device through the conveying device;

[0056] (4) Cutting step, set the pressure applied by the driving mechanism to the die die to be 200 tons, start the drive mechanism, then advance the die die to cut the full-size diffuser plate, and contact t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com