Application of blasting groove broaching method in underground stope of metal mine

A trough-drawing and stope technology, applied in blasting, underground mining, surface mining, etc., can solve problems such as falling rocks and sliding materials in the empty area of cutting shafts, affecting the safety of blasting workers, and the effect of well completion cannot be guaranteed, so as to improve the efficiency of ore preparation , reduce construction costs, optimize the effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The invention adopts the deep-hole blasting construction method to replace the existing cutting-level roadway and cutting-well grooving method, optimizes the mining room cutting process, and avoids the difficulty of forming the cutting well and the hidden danger of blasters working across the open area of the cutting well. , and can ensure the trough effect, greatly shorten the construction period, optimize the process, reduce the construction cost, improve the safety factor, and improve the mine preparation efficiency.

[0020] The present invention adopts the following construction steps to carry out:

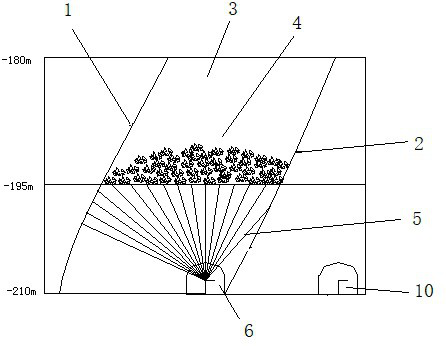

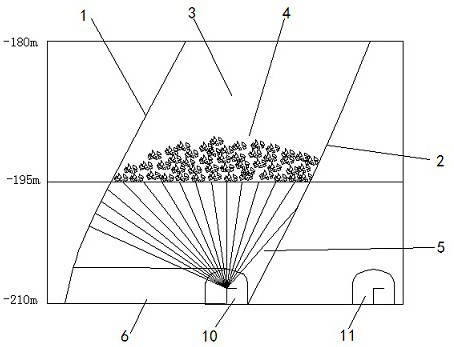

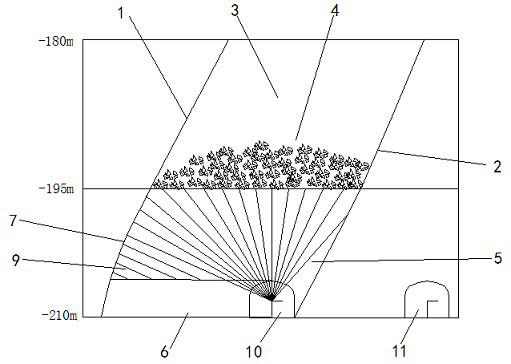

[0021] first step, figure 1 It is shown that two rows of fan-shaped deep-hole blastholes 5 are arranged at the position of the stope cutting groove, the diameter of the deep-hole blastholes 5 is greater than or equal to 50mm, and the row spacing between the two rows of deep-hole blastholes 5 is greater than or equal to 1500mm. The bottom distance of the deep hole bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com