A power drive structure for inspection production line

A power-driven, production-line technology that is applied to conveyor objects, transportation, and packaging, and can solve the problems of complex control structure of the conveyor production line, many personnel in the inspection line, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

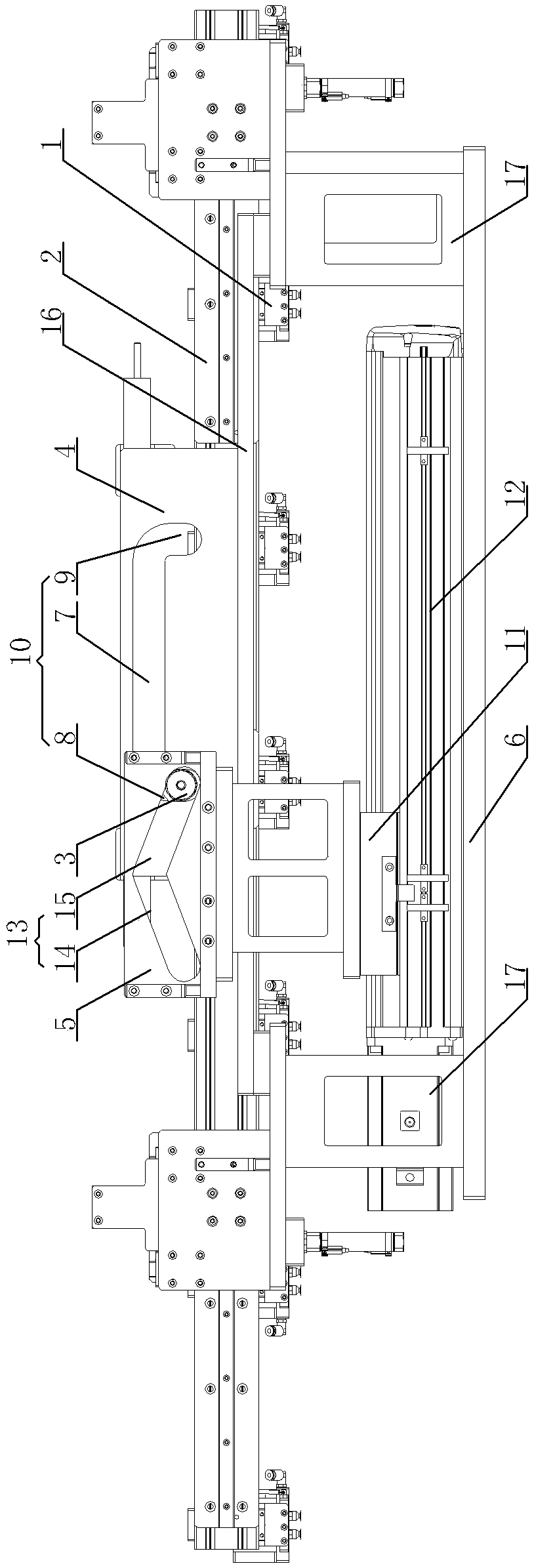

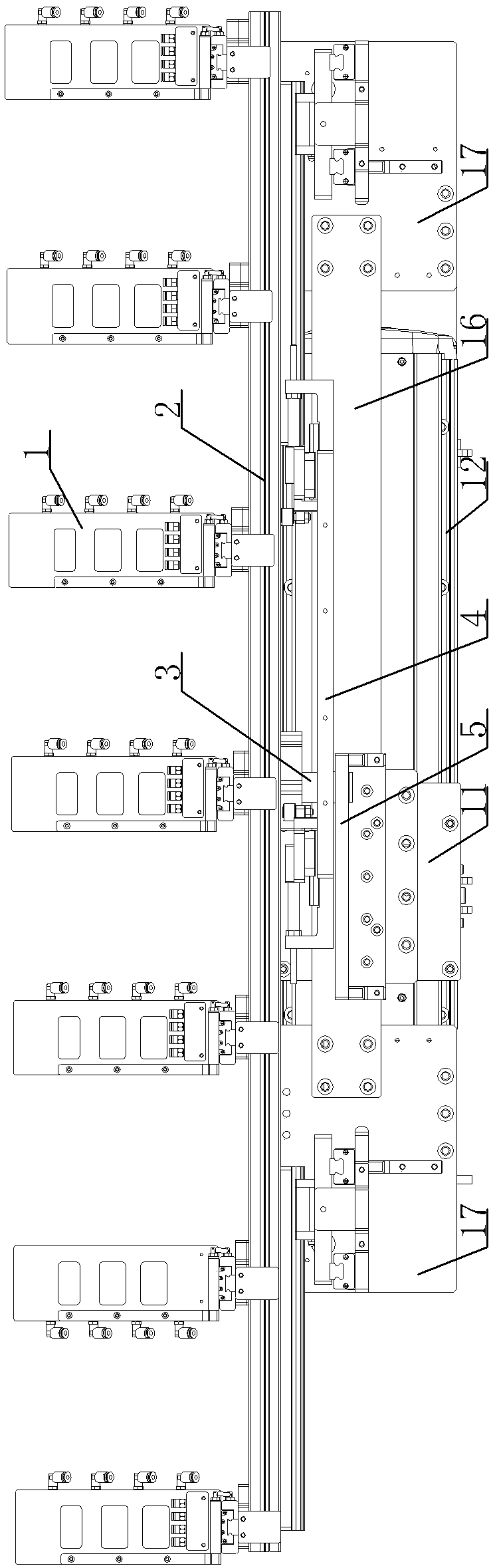

[0014] A battery testing production line, see figure 1 , figure 2 : Its package corresponds to the suction cup assembly 1 of each station, and the outside of each suction cup assembly 1 is fixedly mounted on the connecting cross bar 2 respectively. There are a fixed profiling block 4 and a driving profiling block 5, the fixed profiling block 4 is fixed on the top of the frame 6 through a connector, the fixed profiling block 4 is provided with a horizontal transverse guide groove 7 of the interval length of a single station, The two ends of horizontal transverse guide groove 7 are respectively provided with downward vertical first vertical guide groove 8, the second vertical guide groove 9, the height of the first vertical guide groove 8, the second vertical guide groove 9 is identical, The first vertical guide groove 8, the horizontal transverse guide groove 7, and the second vertical guide groove 9 are combined to form the first fixed profiling groove 10, and the bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com