Teaching method for automatic control system for reproducing coal mining machine teaching

A technology of automatic control system and teaching method, which is applied in the field of coal mining machine control, can solve problems such as uncertainty, and achieve the effects of simple operation and use, reduced labor intensity, and high teaching and learning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

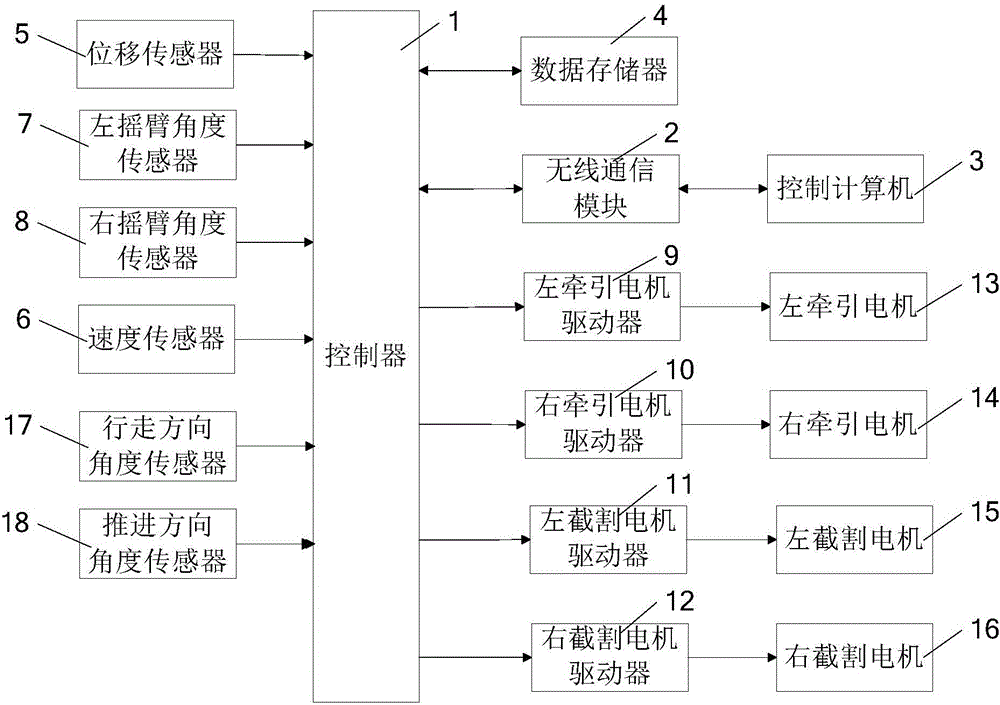

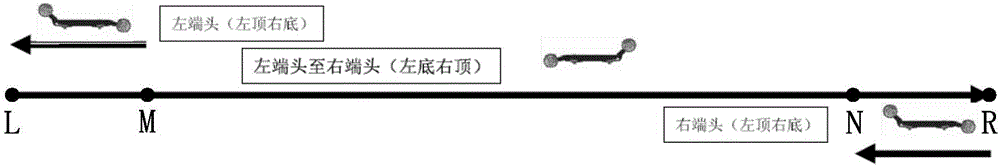

[0049] The teaching method of the automatic control system for the teaching and reproduction of the shearer of the present invention, the shearer is a double-drum shearer, the double-drum shearer includes a shearer body, and is installed on the shearer body The left traveling box on the lower left and the right traveling box installed on the lower right of the shearer body, and the left rocker arm hinged on the left side of the shearer body through the hinge shaft and hinged on the right side of the shearer body through the hinge shaft The right rocker arm on the side, the left travel box is driven by the left traction motor 13, the right travel box is driven by the right travel motor, the front end of the left rocker arm is equipped with a left roller, and the left roller is driven by the left cutting motor 15 drive, the front end of the right rocker arm is equipped with a right drum, and the right drum is driven by the right cutting motor 16; as figure 1 As shown, the automa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com