Globoidal cam mechanism capable of achieving 180-degree reciprocating intermittent swing

A cambered cam, cam technology, applied in the direction of cams, mechanical equipment, transmission devices, etc., to achieve large swing output, meet process requirements, and eliminate the effect of backlash

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

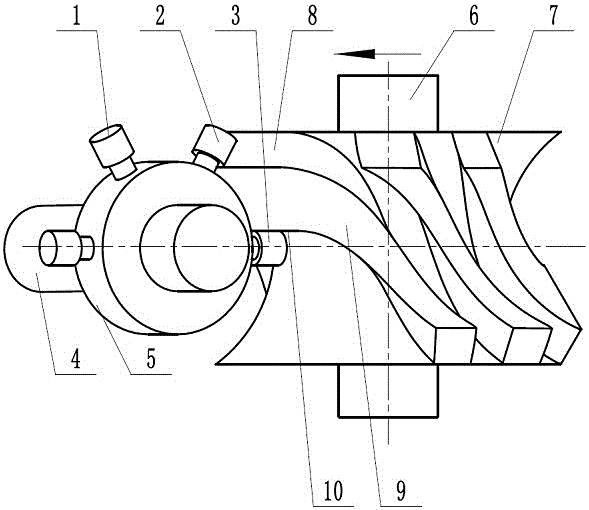

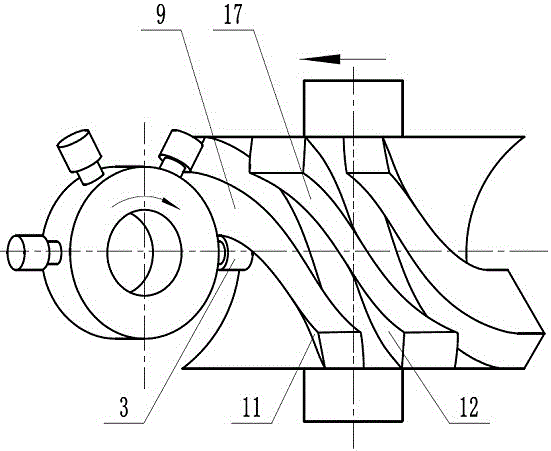

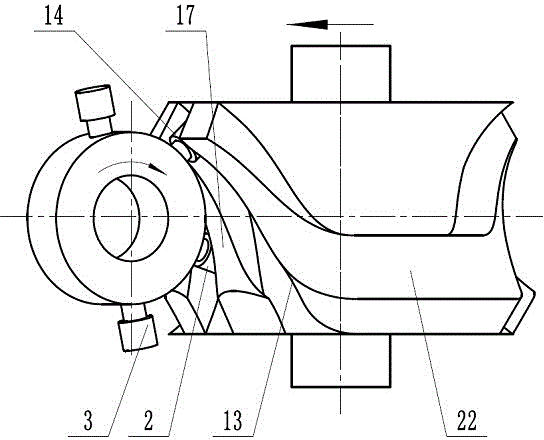

[0018] see figure 1 , an arc cam mechanism that realizes 180-degree reciprocating swing is mainly composed of an input shaft 6, an output shaft 4, an arc cam body 7, and a swing plate assembly. The input shaft 6 and the output shaft 4 are staggered and perpendicular to each other, the cam body 7 is mounted on the input shaft 6 through a key connection, and the oscillating disc assembly is mounted on the output shaft 4 through a key connection. The oscillating plate assembly includes a oscillating plate 5 and a plurality of rollers 1, the axes of the rollers are perpendicular to the axis of the oscillating plate 5, and all the rollers 1 are fixed on the oscillating plate radially along the circumference of the oscillating plate through screw connections and pin connections. 5, the number of rollers is 4, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com