Vertical low-resistance cooling system

A cooling system, low-resistance technology, applied in heat exchange equipment, fixed tubular conduit components, heat exchanger types, etc., which can solve the limitations of heat dissipation and heat exchange effect and structure, the inability of heat exchangers to adapt, and the limitations of application fields, etc. problems, to achieve the effect of facilitating heat conduction, improving service life and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Attached below Figures 1 to 4 The present invention is described in further detail.

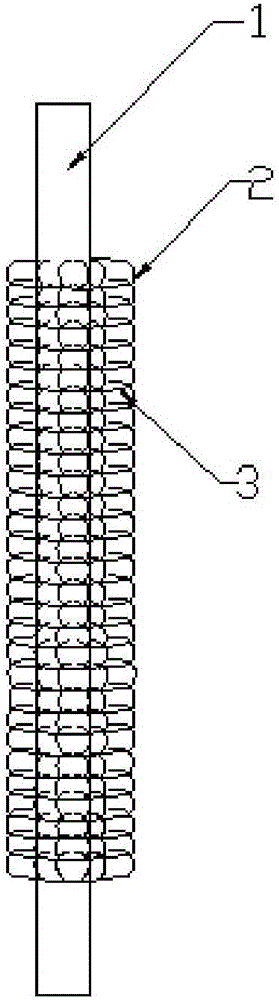

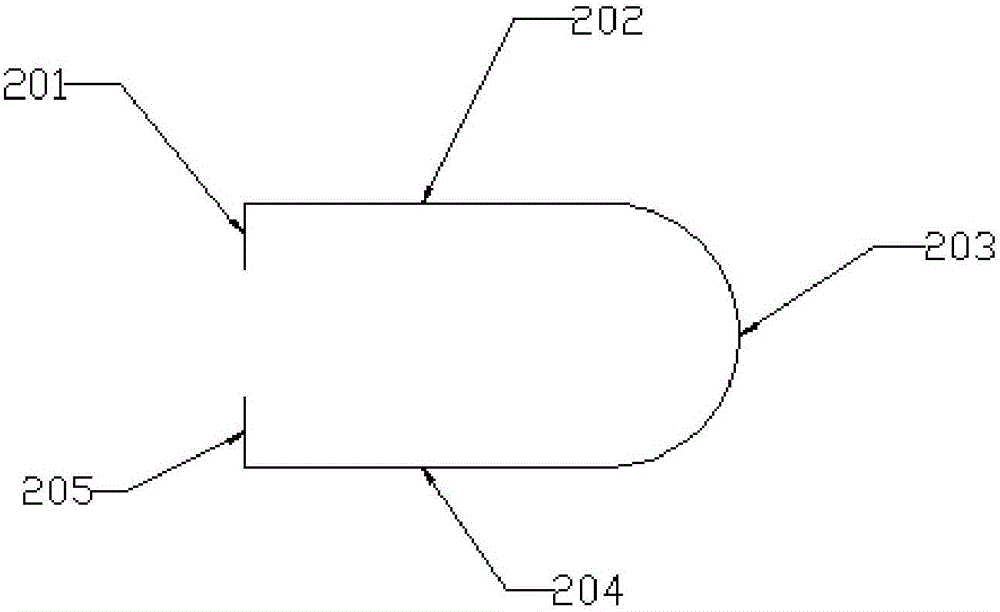

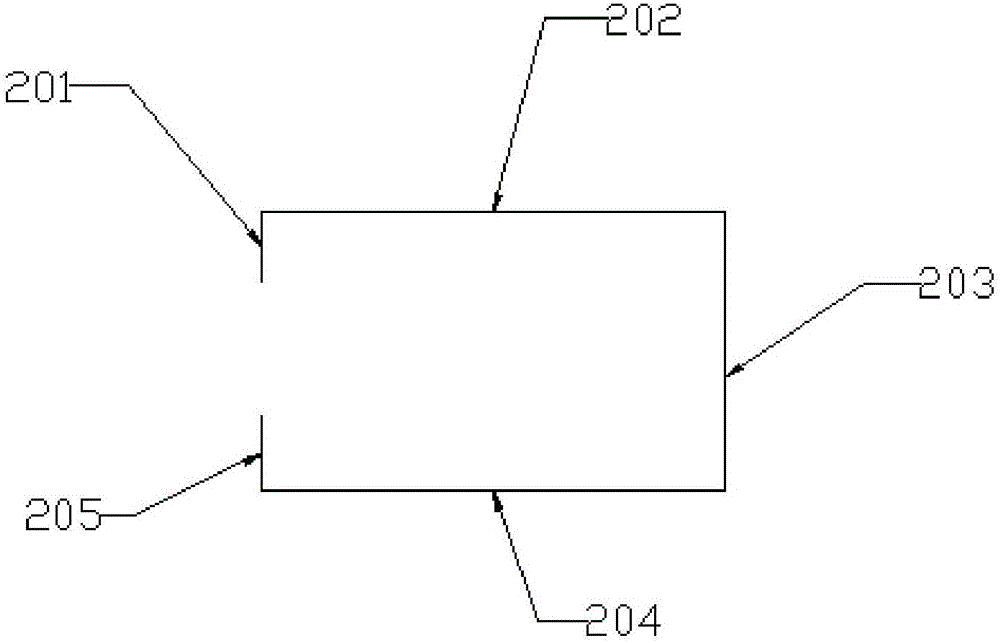

[0015] refer to figure 1 , a vertical low-resistance cooling system, including a heat exchange tube 01, the heat exchange tube 01 includes a metal tube 1 and a plurality of linear bent heat exchange elements 2, and a plurality of linear bent heat exchange elements 2 along the outer wall of the metal tube 1 Arranged in multiple layers and rows, the two ends of each linear bent heat exchange element 2 are fixedly welded on the outer wall of the metal tube 1, and the metal tube 1 is filled with refrigerant. The arrangement and combination of the linear bent heat exchange elements 2 in the vertical low-resistance cooling system of this structure greatly improves the tightness, firmness and stability of the connection between the metal tubes 1, and together form a stable The whole body that is not easy to deform improves its service life and is also conducive to heat conduction. The oute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com