Abe-Koenig roof prism production technology

A technology of Abbe's roof and production process, applied in prisms and other directions, can solve the problems of product accuracy not meeting the requirements of drawings, long grinding time, low work efficiency, etc., to shorten the processing cycle, solve the consistency of precision and size, The effect of improving labor efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] A kind of Abbe roof prism production process of the present embodiment, operation steps are:

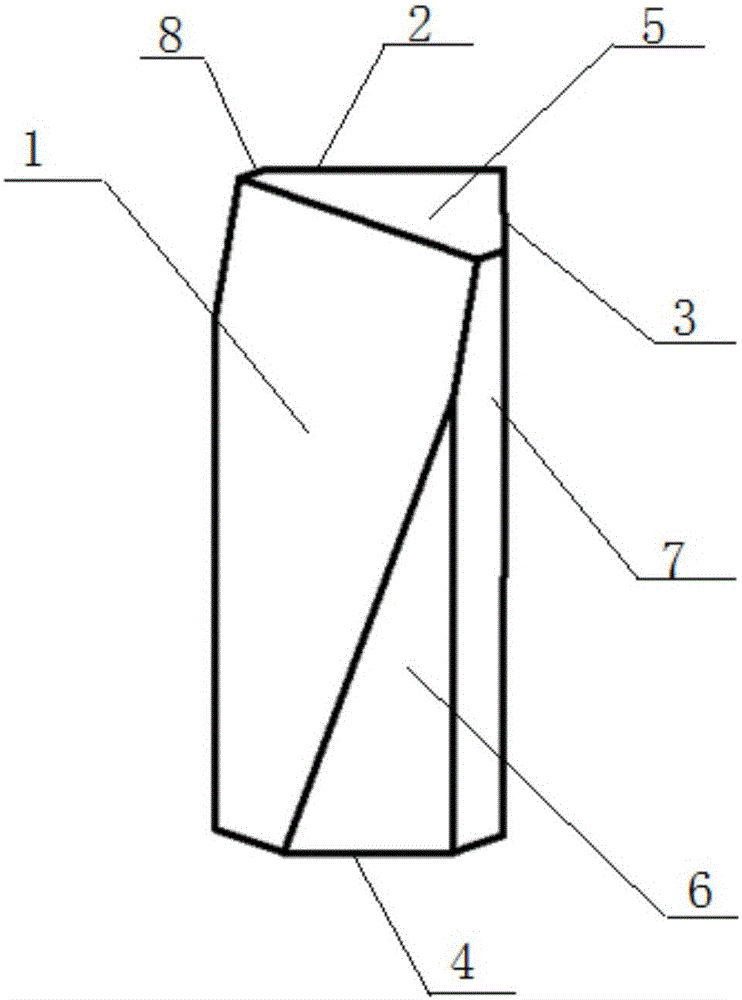

[0043] A. Large-scale processing: After cleaning the square brick body and the Abbe roof prism, use special optical glue to seal such figure 1 The side I7 of each Abbe roof prism shown is evenly bonded to the surface of the square brick body; then the square brick body is transferred to the mirror plate for disk processing.

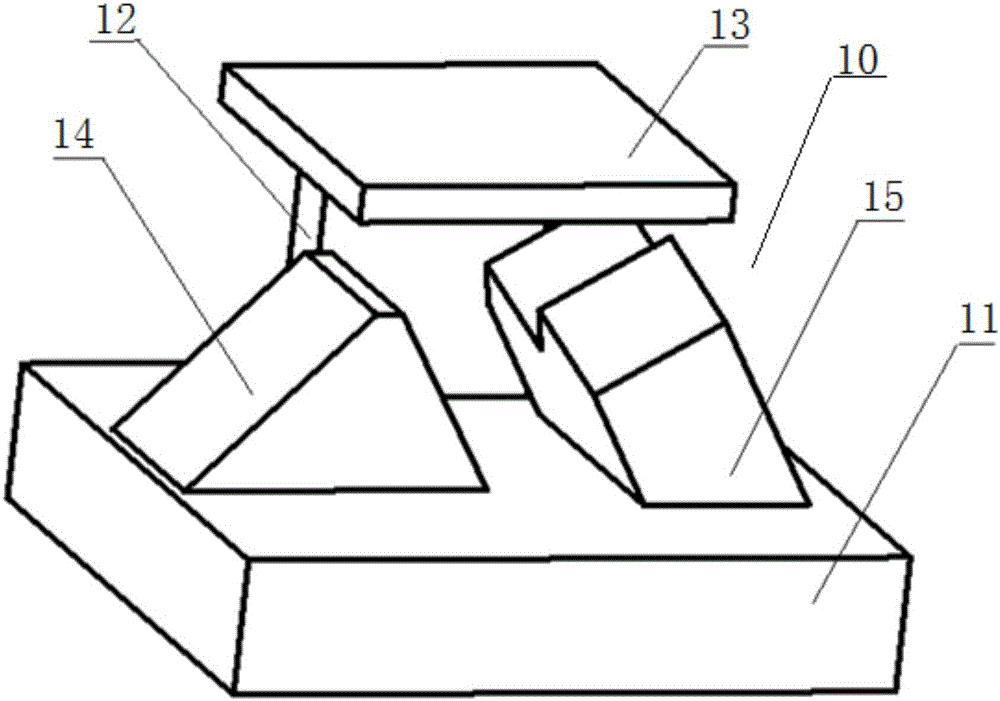

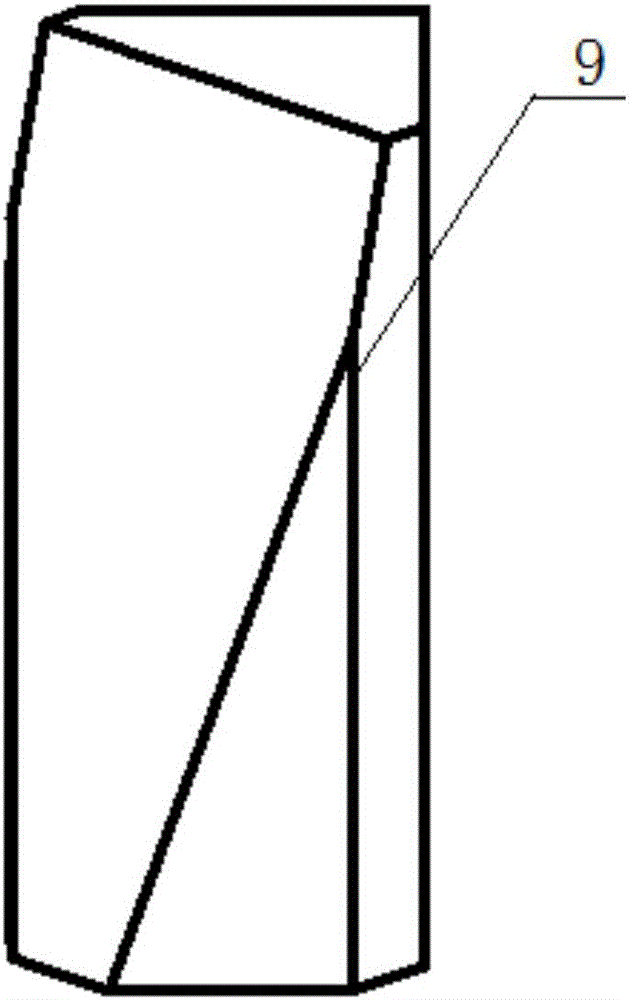

[0044] B, the second side processing: the image 3 The shown Abbe roof prism body 9 is put into the Abbe roof prism tooling 10, the large surface of the Abbe roof prism body 9 faces upwards, and the large surface 1 of the Abbe roof prism faces down and the Abbe roof prism rests After the large surface of the body 9 is connected together to form a pair of glued bodies, it is taken out from the Abbe roof prism tooling 10, and this step is repeated to obtain several glued bodies; each glued body is transferred to the light glued board, And bonding the Abbe...

Embodiment 2

[0049] A kind of Abbe roof prism production process of the present embodiment, the specific steps are basically the same as embodiment 1, and the improvement is: it also includes step G, and in step D, the processing of step G is performed after the glued body is cleaned: the second Wipe the surface 2 or the third surface 3, put the light glue on the 90° square brick, bake it with a 100W incandescent lamp, use soft heat to remove the residual moisture, and after natural cooling, use a brush to brush the protective paint on the glued line to prevent processing During the process, the infiltration of water affects the effect of the optical glue, and then the uniform and symmetrical optical glue is placed on the optical glue board for secondary processing of the roof surface. After the processing is completed, the glued body is separated to obtain the finished product of the Abbe roof prism; the processing Available in matte and polished finishes.

Embodiment 3

[0051] A kind of Abbe roof prism production process of this embodiment, the specific steps are the same as embodiment 2, the improvement is: the comprehensive size of the Abbe roof prism body 9 is 8mm larger than that of the Abbe roof prism, evenly distributed, and the tolerance is 0.01mm Within, each angle accuracy is within 20", the surface aperture of each surface is 0.5 circle, the error is 0.2 circle, and the smoothness of each surface is uniform, which ensures the processing accuracy of Abbe roof prism processing; each side must be poured to 0.5 mm, the width of the trihedral angle is 1.5mm, so as to avoid hurting hands during processing. The accuracy of the 90° angle of the square brick body in step A is within 30 "; the cleaning step is to use a white cleaning cloth with a mixed liquid solvent Clean the square brick backing body and the Abbe roof prism; a total of 4 pieces of Abbe roof prisms are bonded to each square brick backing body, and 10 square brick backing bodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com