A peripheral exposure method in the manufacture of liquid crystal display panels

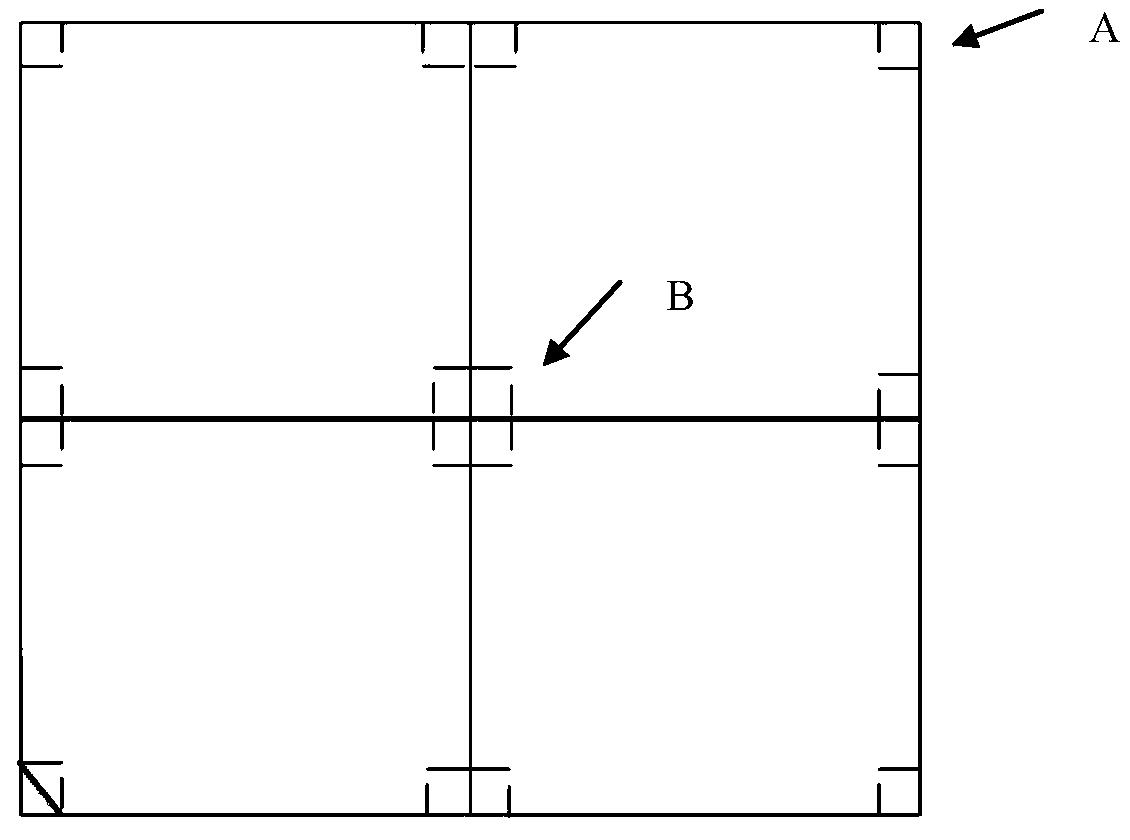

A technology of liquid crystal display and exposure method, which is applied in the direction of photolithography exposure device, microlithography exposure equipment, pattern surface photolithography technology, etc., can solve the problem that the peripheral exposure pattern affects the utilization rate of the effective area of the motherboard, and achieves Improve the effective area utilization rate, rational design, and reduce the effect of substrate use area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

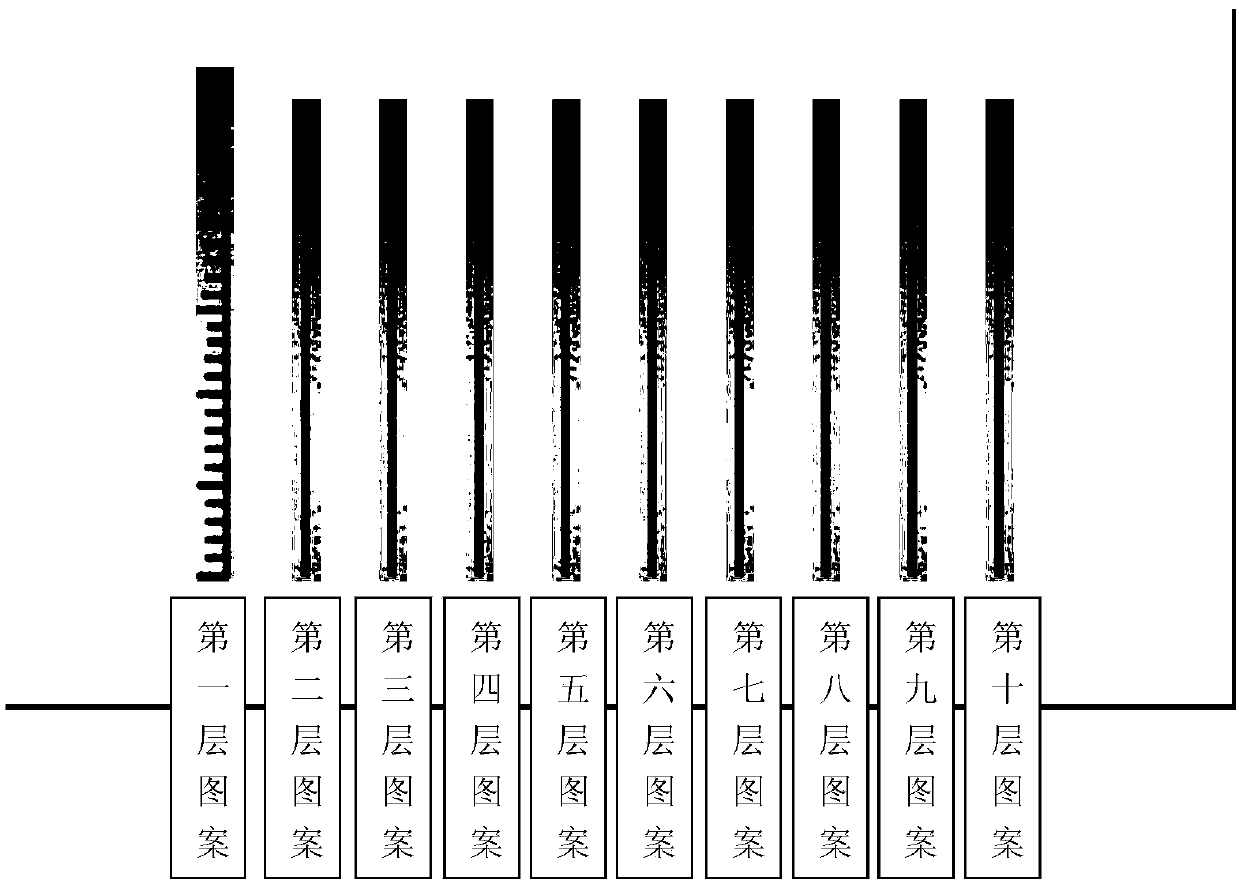

[0036] For example, in the manufacturing process of a certain liquid crystal display panel, 10 layers of thin film patterns need to be formed on the mother substrate. The first layer is a metal film layer, the second layer is a metal film layer, and the third to tenth layers are non-metal film layers. The film is a copper-titanium alloy film, which is yellow and dark in color, which is indistinguishable from the photoresist by naked eyes. The non-metal film is composed of SiNx, SiO 2 Or made of IGZO material, the color is lighter and transparent, which can be easily distinguished from the photoresist with the naked eye.

[0037] For each scan (scan), the formation of 10 layers of thin film patterns requires 10 masks, which are named the first mask, the second mask, ... the 10th mask, corresponding to the different layers formed Thin film patterns, that is, the first mask is used to form the first layer of thin film patterns, the second mask is used to form the second layer of thin...

Embodiment 2

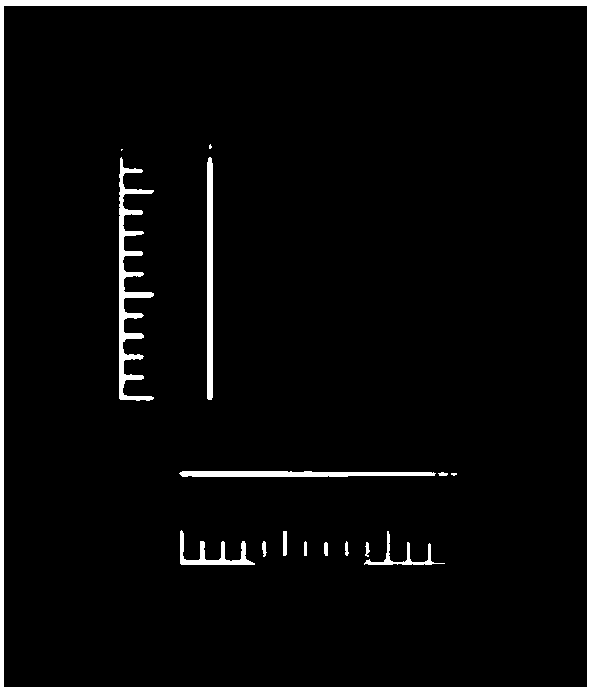

[0041] For example, in the manufacturing process of a certain liquid crystal display panel, it is necessary to form an N-layer film pattern on the mother substrate. The N-layer film consists of multiple metal film layers (copper-titanium alloy film, yellow) and multiple non-metal film layers (color translucent). Or transparent) composition, peripheral exposure, such as Image 6 , The peripheral pattern of the first layer of film is a measuring scale, and a single row of patterns is beneficial to the reading of other layers. The peripheral pattern positions of the second layer to the next metal film layer overlap, sharing a row of patterns. If the next layer of the metal film layer is still a metal film layer, the peripheral patterns of the next layer of the metal film layer are still in a single line of patterns; if the next layer of the metal film layer is a non-metal film layer, the next layer of the metal film layer will arrive The peripheral pattern positions of the next m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com