Controller for pallet of cement prefabricated part

A technology of prefabricated components and control devices, applied in the direction of program control, computer control, general control system, etc., can solve the problems of high cost, difficult maintenance, inability to achieve modularization, intelligentization, etc., to improve performance and increase the maximum allowable length Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order for those skilled in the art to better understand the technical solution of the present invention, a new pallet control device for cement prefabricated components provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

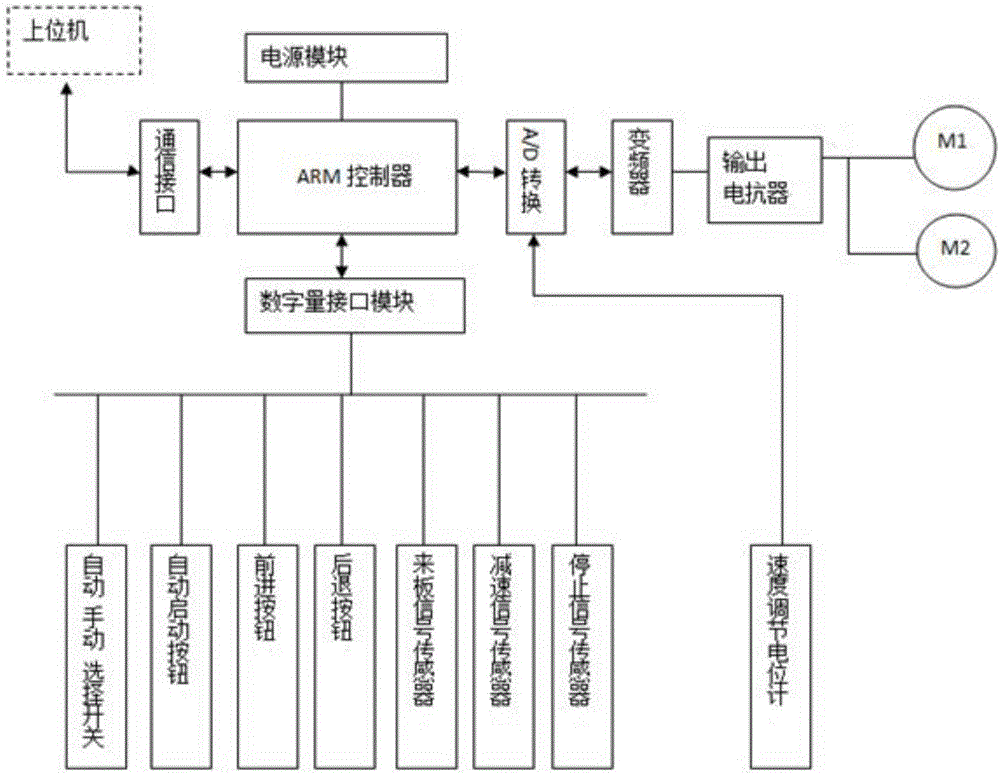

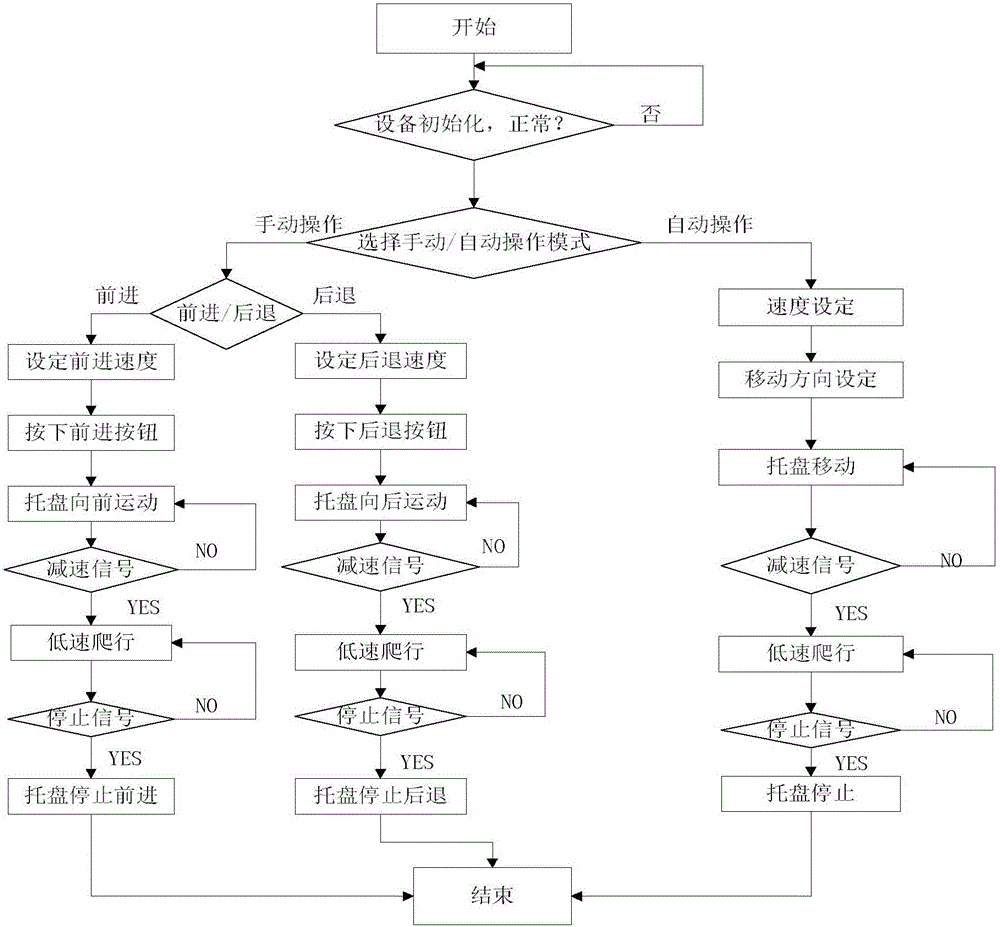

[0028] Referring to the accompanying drawings, a pallet control device for cement prefabricated components includes an ARM7 controller, a power supply module, a communication interface module, an A / D conversion module, a frequency converter, an output reactor, a variable frequency motor M1, a variable frequency motor M2, and a digital interface module , automatic / manual selector switch, automatic start button, forward button, backward button, incoming board signal sensor, speed setting potentiometer, deceleration signal sensor, stop signal sensor, the described ARM7 controller is connected with the peripheral equipment through the interface module, Collect extern...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com