Management system of lithium battery production line

A management system and production line technology, applied in the field of control systems, can solve problems such as lack of self-judgment, scattered management systems, failure to correct fault points in time, etc., to facilitate remote monitoring and save storage space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

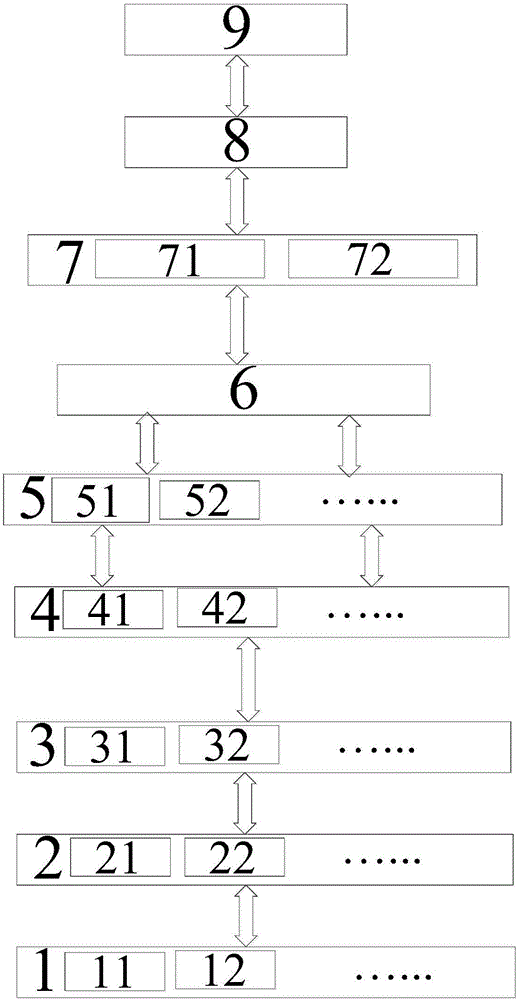

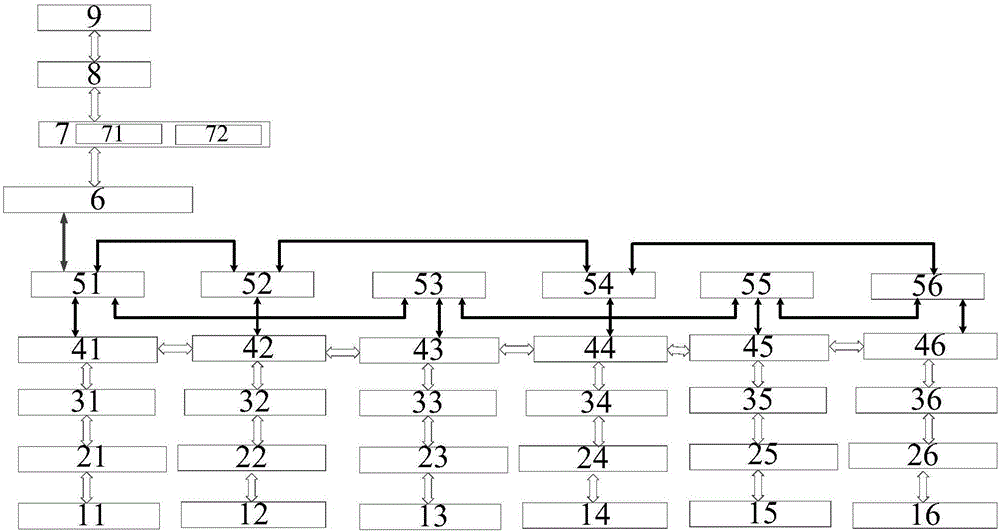

[0021] Embodiment 1 provides a management system of a lithium battery pole piece production line (referred to as the management system, see figure 2 ), including a controller part 1, a wireless network client part 2, a wireless network device part 3, an access layer network 4, a convergence layer network 5, a main switch 6, a production line control center 7, a network disk 8 and a terminal device 9; The controller part 1 includes a first controller 11, a second controller 12, a third controller 13, a fourth controller 14, a fifth controller 15 and a sixth controller 16; the wireless network client part 2 Including the first wireless network client 21, the second wireless network client 22, the third wireless network client 23, the fourth wireless network client 24, the fifth wireless network client 25 and the sixth wireless network client 26; The wireless network device part 3 includes a first wireless network device 31, a second wireless network device 32, a third wireless ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com