Self-damping double-reel pay-off device and application method thereof

A technology with built-in damping and wire-releasing devices, which is applied to conductor/cable supply devices, electrical components, circuits, etc., can solve problems such as difficult maintenance, inappropriate magnetic powder motors, and difficulty in ensuring power supply, so as to increase twisting tension and increase Scope of application, effect of increasing aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

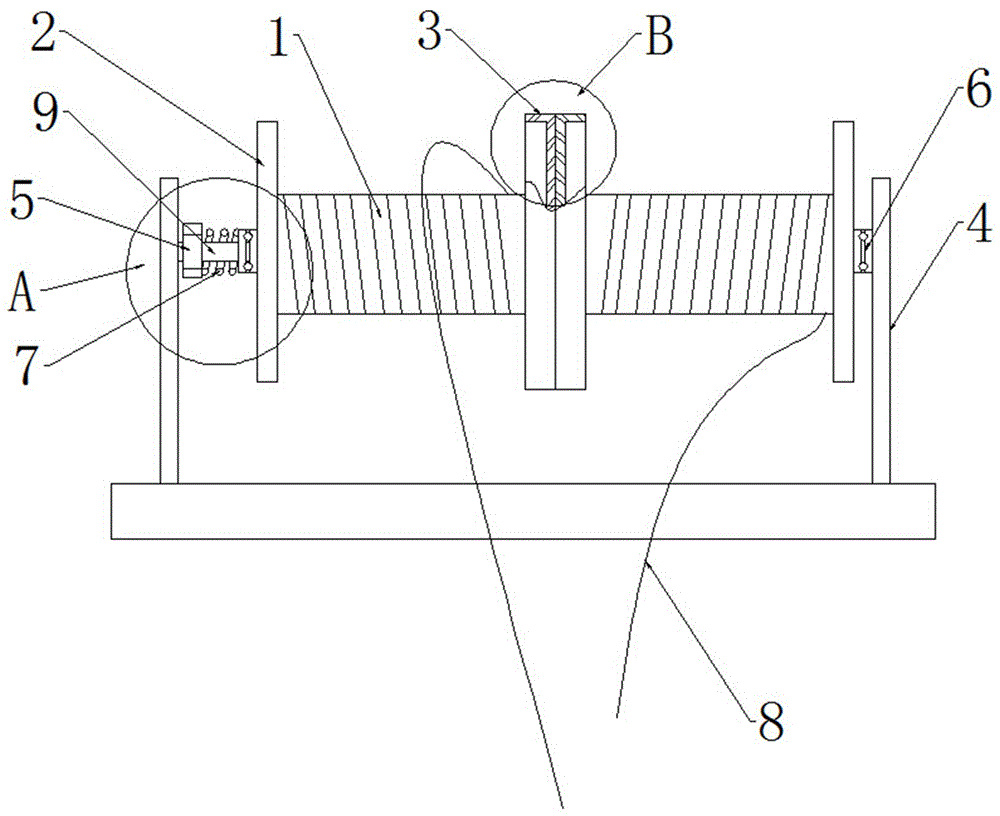

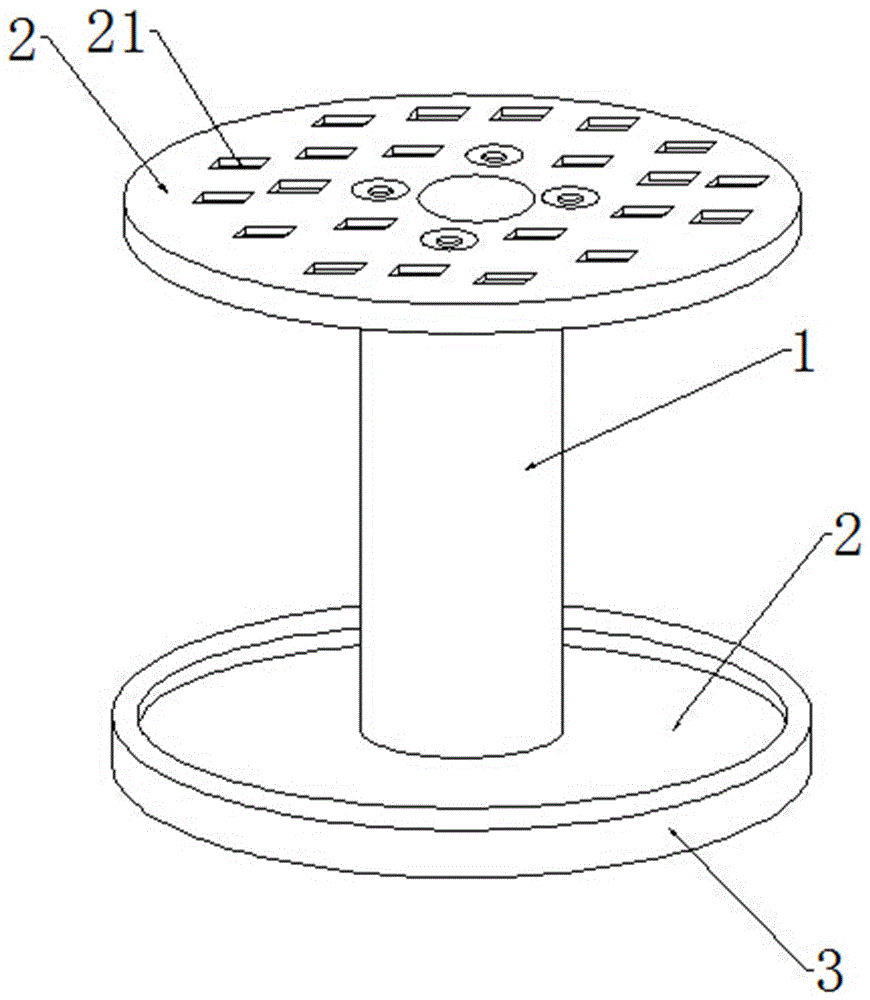

[0020] Embodiment 1 A double-disk pay-off device with its own damping, see Figure 1-3 : Including the installation shaft 9, the pay-off reel 1, and the two sets of pay-off reels 1 that are wound in opposite directions with the wire core 8 contradicting each other and assembled on the installation shaft 9, and the friction plates 3 are correspondingly provided on the end faces of the two groups of pay-off reels 1 that conflict with each other The installation shaft 9 is correspondingly connected to the installation bracket 4, and the installation shaft 9 is provided with a pressure regulating structure corresponding to the pay-off reel 1.

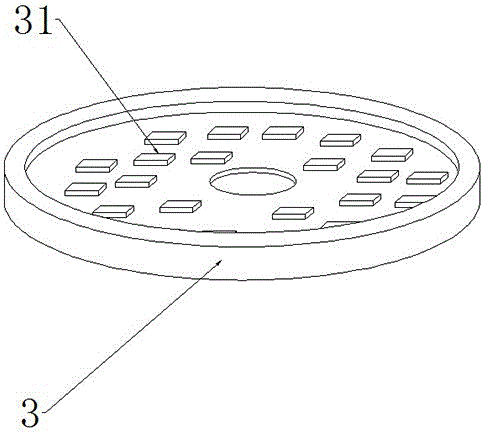

[0021] The two ends of the pay-off reel 1 are correspondingly provided with a limit disc 2, and the friction plate 3 is correspondingly set on the limit disc 2 through the installation groove matching the end surface of the limit disc 2; the side wall of the limit disc 2 is distributed with blind holes 21 , the inner wall of the friction pl...

Embodiment 2

[0030] Embodiment 2 A double-disk pay-off device with its own damping, see Figure 1-3 : A double-disk pay-off device with self-damping, comprising an installation shaft 9, a pay-off reel 1, two sets of pay-off reels 1 with wire cores 8 reversely wound against each other and assembled on the installation shaft 9, the two groups of release reels 1 The friction plates 3 are correspondingly provided on the conflicting end surfaces of the wire reels 1; the installation shaft 9 is correspondingly connected to the installation bracket 4, and the installation shaft 9 is provided with a pressure regulating structure corresponding to the pay-off reel 1.

[0031] The two ends of the pay-off reel 1 are correspondingly provided with a limit disc 2, and the friction plate 3 is correspondingly set on the limit disc 2 through the installation groove matching the end surface of the limit disc 2; the side wall of the limit disc 2 is distributed with blind holes 21 , the inner wall of the frict...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com