Diaphragm with enhanced middle-low frequency bands

A low-frequency, fixed diaphragm technology, applied in the direction of diaphragm structure, can solve the problems of poor mid-range and low-frequency sound quality of the diaphragm, heavy metal quality, poor rigidity, etc., to achieve clear low frequency, good rigidity, and conducive to molding Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

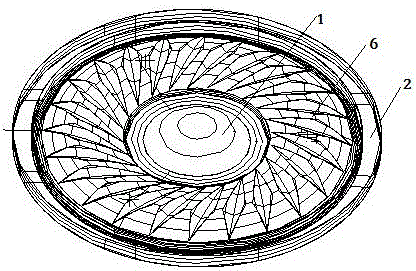

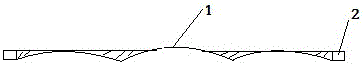

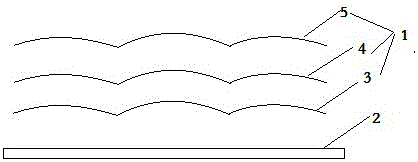

[0014] As shown in the attached figure, a vibrating membrane with enhanced middle and low frequencies includes a vibrating membrane 1 and a copper ring 2 for fixing the vibrating membrane. The copper ring and the vibrating membrane are bonded together with heat-sensitive glue, because the heat-sensitive glue The price is cheap, and the effect is good; the diaphragm 1 includes three layers: the first layer is the coating layer 3, and the coating material is titanium; the second layer is the base layer, and the base layer is polyarylate layer 4; the third layer is a composite layer, the composite layer It is a polyurethane layer 5; the coating layer 3 is located between the base layer and the composite layer, and the coating layer is electroplated on the base layer, and the coated base layer and the composite layer are combined to form a diaphragm with a thickness of 0.008mm~0.300mm. Compositing in a conventional way; polyarylate is soft, good for distortion, clear at low frequen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com