Substrate separation apparatus for stacked body

一种剥离设备、衬底的技术,应用在层压、分层产品、电固体器件等方向,能够解决不能玻璃衬底施加微细等问题,达到防止解除吸附、可靠剥离的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

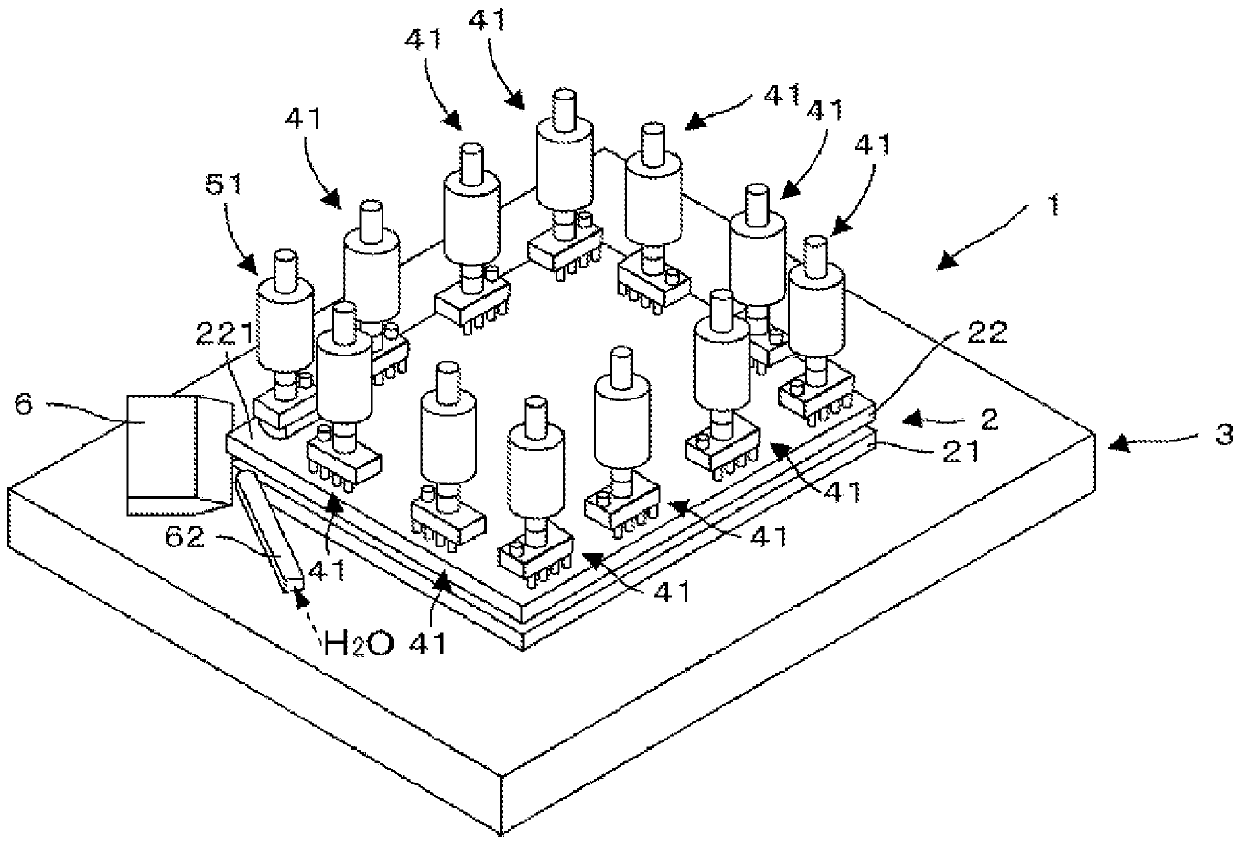

[0027] Embodiment 1 of the present invention will be described below with reference to the drawings. figure 1 It is an overall perspective view showing the substrate peeling equipment of the laminated body according to Embodiment 1 of the present invention. The substrate peeling equipment 1 according to Embodiment 1 includes a fixing table (fixing tool) 3 for fixing the laminated body 2 , a first adsorber 4 , a second adsorber 5 , and a wedge tool (peeling start unit) 6 . Note that in figure 1 The details of the power mechanism and the like included in each component are not shown in the figure.

[0028] The laminated body 2 corresponds to the thin element layer 23 sandwiched by the first substrate 21 and the second substrate 22 (refer to Figure 6 , Figure 7 as well as Figure 9 ) components. For example, although the first substrate 21 and the second substrate 22 are not particularly limited, hard substrates such as glass substrates may be used. For example, as the el...

Embodiment approach 2

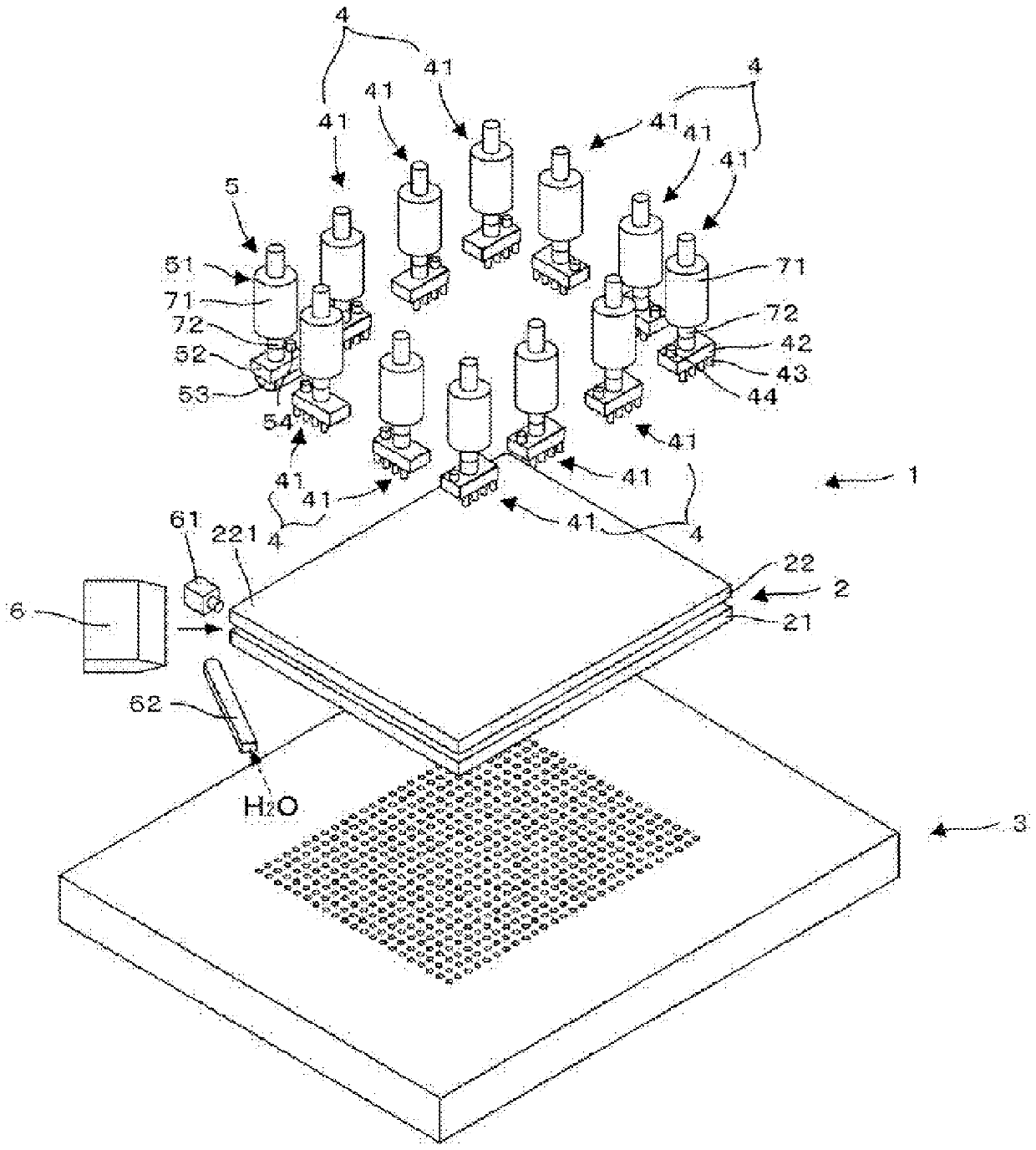

[0041] Figure 11 The substrate peeling equipment of the laminated body of Embodiment 2 of this invention is shown. Such as Figure 11 As shown, the substrate peeling apparatus 11 of Embodiment 2 is in addition to the substrate peeling apparatus 1 of Embodiment 1 described above (refer to Figure 5 ) has four first adsorption portions 411 , 412 , 413 , and 414 arranged at the central portion of the second substrate 22 in addition to the constituent elements. That is, in the substrate peeling apparatus 1 of Embodiment 1 described above, the first suction portion 41 and the second suction portion 51 are disposed only on the edge of the second substrate 22 . However, in the substrate peeling apparatus 11 according to Embodiment 2, four first suction parts 411 , 412 , 413 , and 414 are additionally arranged on the central portion of the second substrate 22 .

[0042] By adopting the above structure, the first adsorption portion can be arranged on the entire surface of the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com