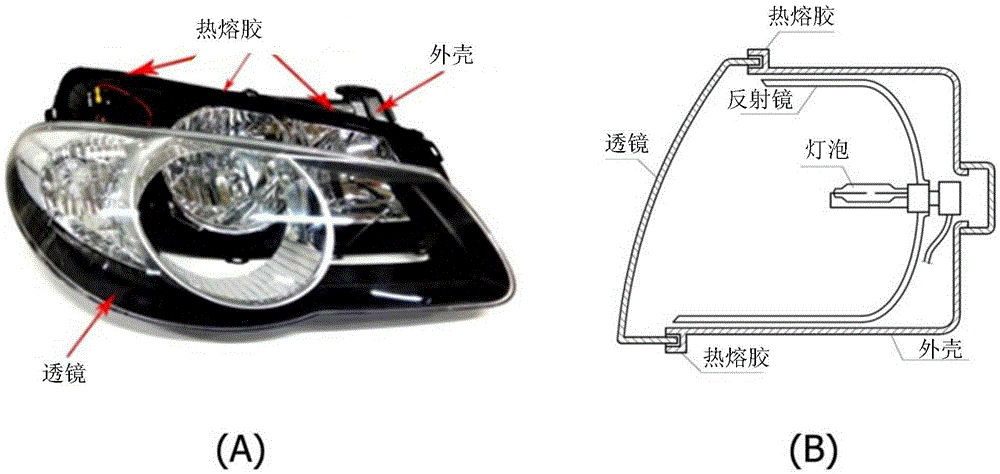

Method for preparing hot-melt adhesive composition and hot-melt adhesive composition prepared thereby

A composition, hot melt adhesive technology, applied in the direction of adhesives, adhesive types, adhesive additives, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038] The preparation method of the hot melt adhesive composition of the present invention will be described in detail below.

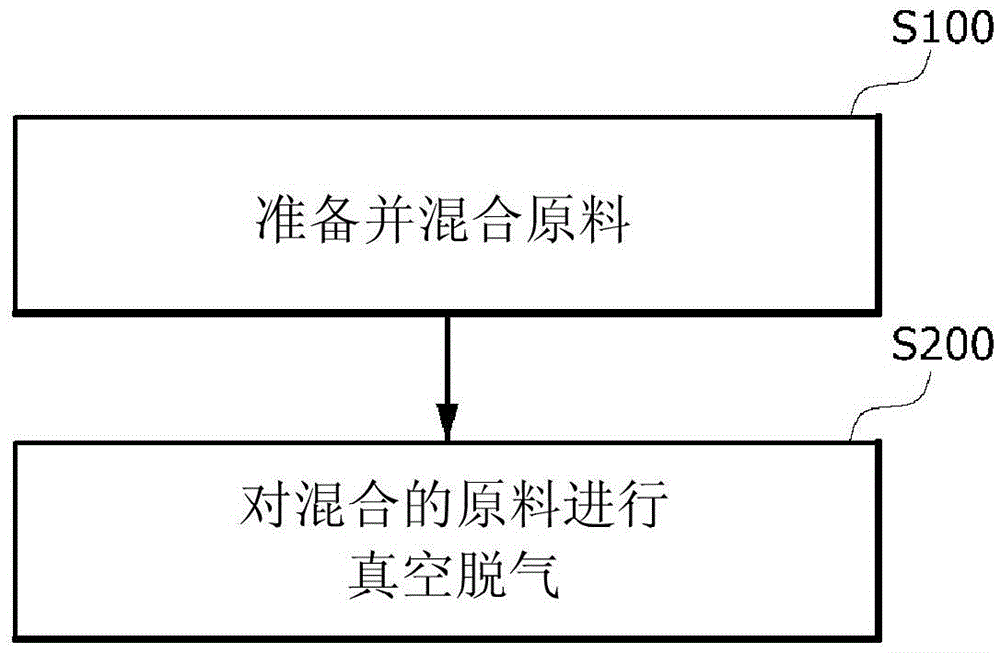

[0039] figure 2 It is a process flow diagram schematically showing a method for preparing a hot melt adhesive composition described in an embodiment of the present invention.

[0040] refer to figure 2 , The method for preparing a hot melt adhesive composition of the present invention includes the following steps: (S100) preparing and mixing raw materials; and (S200) vacuum degassing the mixed raw materials.

[0041] Prepare and mix ingredients

[0042] The step of preparing and mixing raw materials (S100) is carried out, the purpose of which is to prepare and mix the resin components required for preparing the hot melt adhesive composition.

[0043] The raw materials include butyl rubber, ethylene propylene diene monomer (EPDM) rubber, styrenic block copolymers, amorphous polyalphaolefin (APAO) and tackifying resins, wherein the styrenic bloc...

Embodiment 1

[0089] As shown in the following table 1, the following raw materials are mixed in a mixer: the total weight of the hot melt adhesive composition is 100wt%, 14.5wt% butyl rubber; 14.5wt% ethylene propylene diene (EPDM) rubber; 9.6 wt% of styrene block copolymer containing styrene-isoprene-styrene (SIS) rubber; 7.7 wt% of amorphous polyalphaolefin (APAO); 19.4 wt% of aliphatic petroleum resin as Tackifying resin; 9.6wt% rosin ester as tackifying resin; 9.6wt% terpene resin as tackifying resin; 9.6wt% plasticizer containing polyisobutylene; 4wt% maleic anhydride polypropylene; 1wt% phenolic antioxidant; and 0.5wt% UV stabilizer. Then, the mixed raw materials were vacuum degassed for 4 hours under the conditions of a vacuum degree of 80 mmHg and a temperature of 170° C. using a vacuum pump, thereby obtaining the hot melt adhesive composition of the present invention.

[0090] Then 1.5 g of hot melt adhesive formed from the hot melt adhesive composition was applied to polypropyle...

Embodiment 2 to Embodiment 4

[0092] The hot melt adhesive composition of the present invention was prepared in the same manner as described in Example 1, except that the composition was prepared according to the components, contents and vacuum conditions shown in Table 1 below. Swellable samples were prepared using the prepared compositions.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com