Pilot fuel injection adaptation

A technology for igniting fuel and fuel injectors, which is applied in the directions of fuel injection control, combustion engine, internal combustion piston engine, etc., can solve problems such as difficulty in determining the error of the transfer function of the fuel injector, and difficulty in accurately updating the transfer function of the fuel injector, etc. Achieve improved engine emissions and combustion stability, improved conditioning, reduced emissions and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

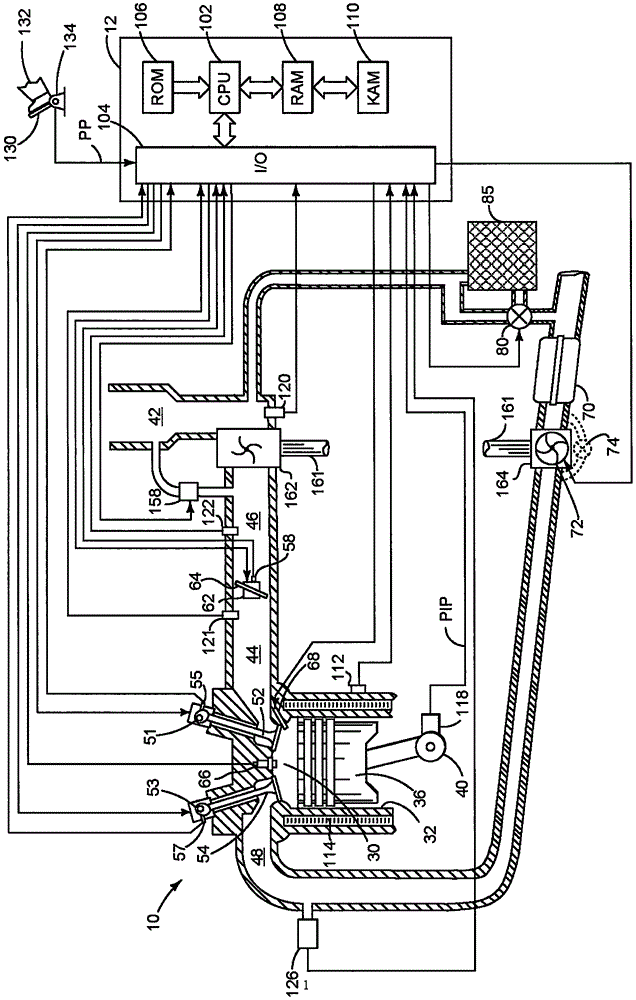

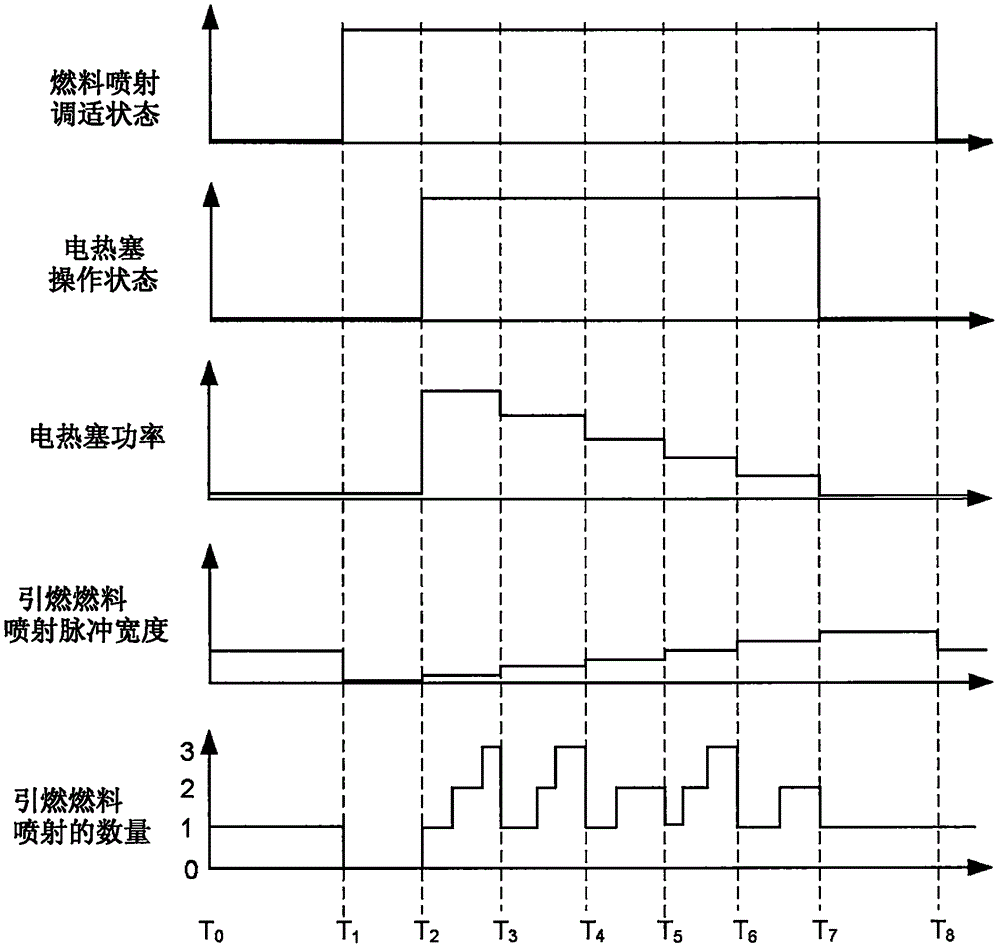

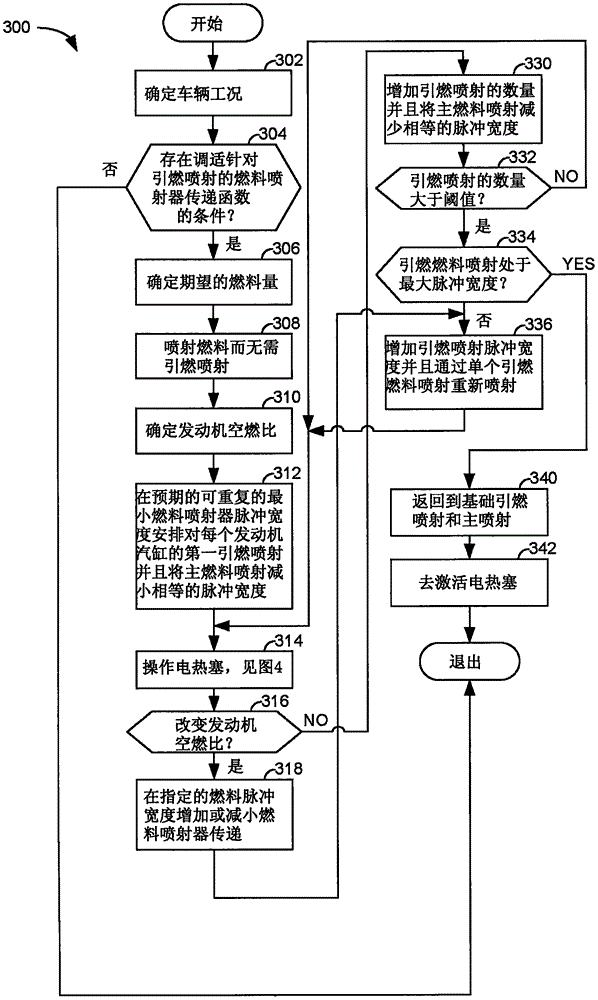

[0011] The present description relates to tuning fuel injector transfer functions to reduce engine noise and improve combustion within engine cylinders. figure 1 An example of a boosted diesel engine is shown, where image 3 and Figure 4 A method can adjust glow plug operation and combustion phasing to improve engine torque production, combustion stability, and reduce engine combustion noise. The engine operating sequence is figure 2 is shown in , where the fuel injector transfer function is tuned. image 3 and Figure 4 An example method for adjusting a transfer function describing fuel injector operation is shown.

[0012] refer to figure 1 , an internal combustion engine 10 comprising a plurality of cylinders is controlled by an electronic engine controller 12, figure 1 One cylinder of the plurality of cylinders is shown. Engine 10 includes combustion chamber 30 and cylinder walls 32 with piston 36 seated therein and connected to crankshaft 40 . Combustion chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com