Production method of premna jelly

A production method and technology of rotten bean curd, which is applied in the field of rotten rotten leaves, can solve problems such as difficulty in adapting to market-oriented promotion, unsuitable color, fragrance, and easy dehydration of rotten tofu, so as to improve the taste and color, and improve the relative purity degree, to ensure the effect of juice yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

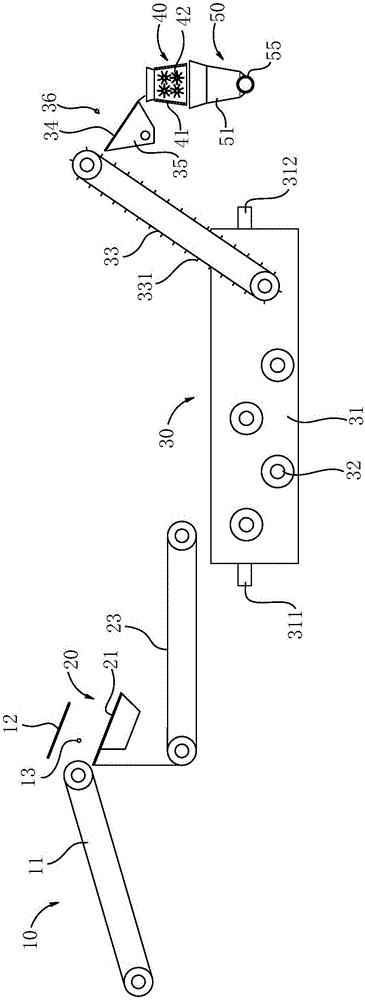

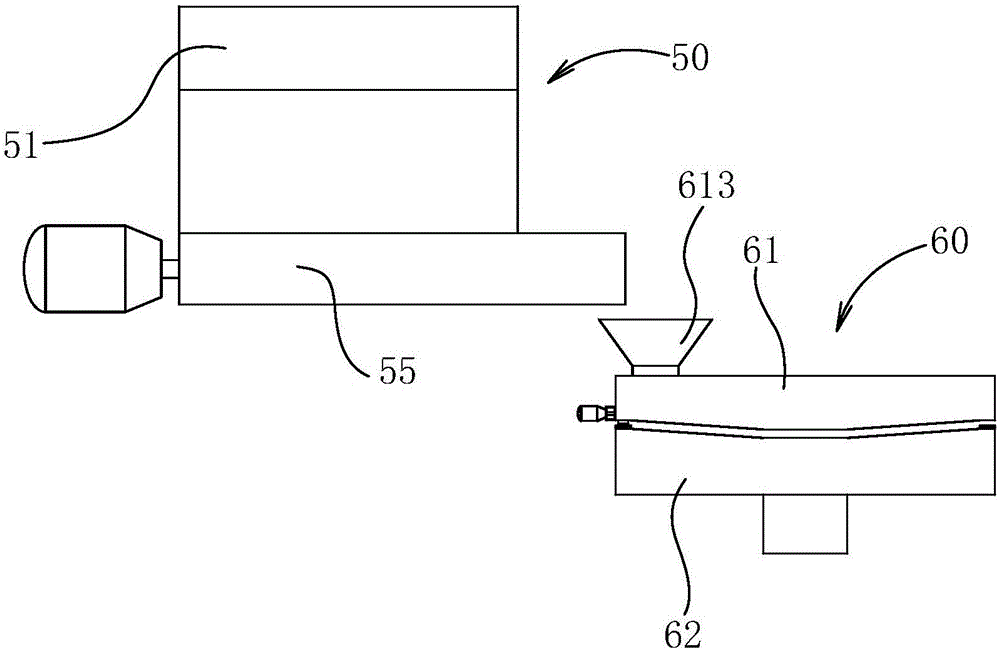

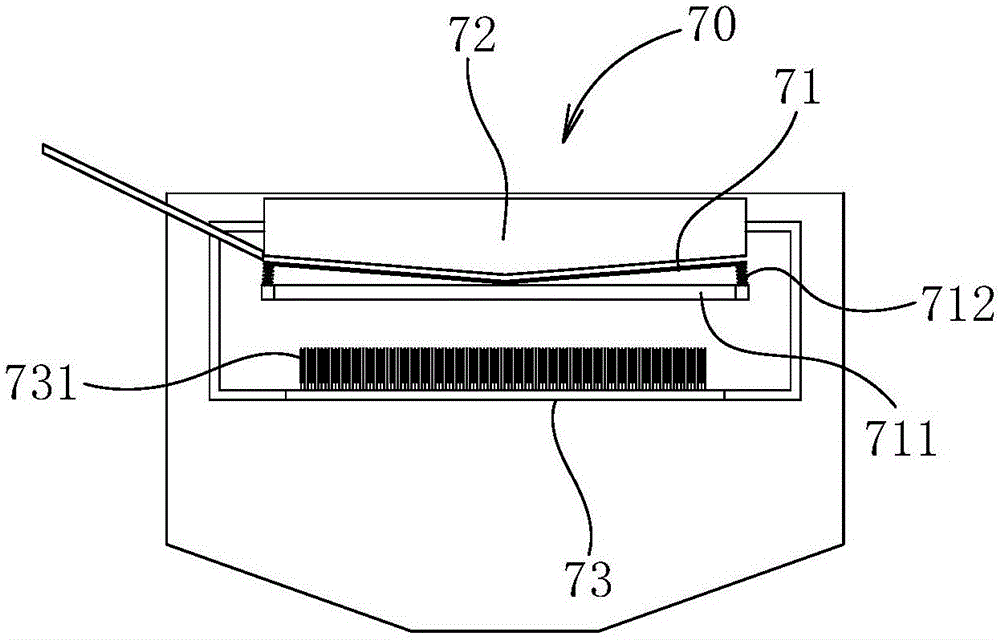

[0100] Put the fresh pickled bean curd leaves on the bamboo mat and spread them naturally for 2-8 hours; microwave the green bean curd leaves that are naturally spread, control the power of microwave deenzyming to 1-2kw, and the time for microwave deenzyming to be 120-150s ; Cool the bean curd leaves after the greening treatment for 20 to 30 minutes; send the revived bean curd leaves to the bean curd leaf pulping system for impurity removal and refinement treatment to obtain a bean curd pulp, the bean curd leaves Add 4 to 6 times the weight of water to the leaves for pulping;

[0101] The carrageenan of 1.2 parts by weight, the konjac gum of 1 part by weight, the xanthan gum of 0.2 parts by weight, the citric acid of 0.1 parts by weight, the calcium lactate of 0.2 parts by weight, the Vc of 0.05 parts by weight are mixed and heated and boiled into pectin liquid ;

[0102] Mix 18 parts by weight of bean curd slurry and 1 to 2 parts by weight of hair spice liquid, stir and heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com