Automatic correction method for water adding quantity of humidifying equipment

A humidification equipment and water addition technology, which is used in the preparation of tobacco, electric controllers, controllers with specific characteristics, etc., can solve the problem that the moisture at the outlet of the first material deviates greatly, the moisture at the outlet of the humidification equipment fluctuates greatly, and affects the product. quality and other issues, to achieve good control effect, good industrial application value, promotion and application prospects, and the effect of ensuring export moisture indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

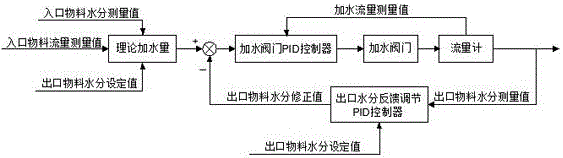

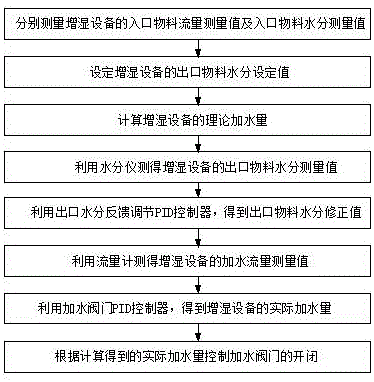

[0028] Such as figure 1 and figure 2 As shown, a method for automatically correcting the amount of water added to a humidifying device according to the present invention includes the following steps in sequence:

[0029] (1) Use the electronic belt scale and the moisture meter to measure the inlet material flow measurement value a and the inlet material moisture measurement value b of the additional equipment respectively, and then enter step (2);

[0030] (2) Set the outlet material moisture setting value c of the humidifying device according to the process standard of the humidifying device, and then enter step (3);

[0031] (3) According to the inlet material flow measurement value a, the inlet material moisture measurement value b and the outlet material moisture setting value c, calculate the theoretical water addition y of the humidification device, and then enter step (4);

[0032] The calculation process of the theoretical water addition y of the humidification equi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com