Reactor for liquid mixture

A liquid mixing and reaction kettle technology, applied in mixers, fluid mixers, mixers with rotary stirring devices, etc., can solve the problems of long stirring time, uneven stirring, and inability to perform stirring, and achieve short stirring time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

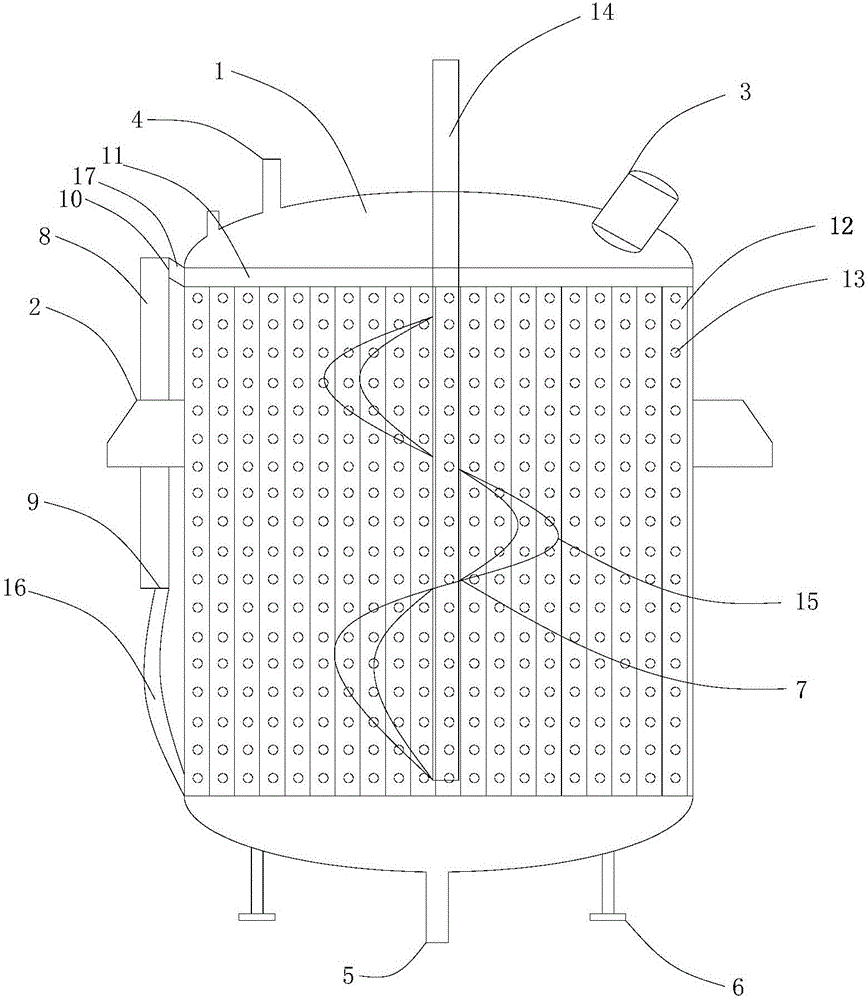

[0020] A reaction kettle for liquid mixing, comprising a kettle body 1, an ear seat 2, an observation port 3, a feeding port 4, a material discharge port 5 and a heating pipe 6 are arranged on the kettle body 1, a stirring device 7 is arranged in the kettle body 1, and a stirring device 7 is arranged in the kettle body 1. The body 1 is provided with a liquid pump 8, the liquid inlet 9 of the liquid pump 8 is connected with the bottom of the kettle body 1, and the liquid outlet 10 of the liquid suction pump 8 is connected with the upper part of the kettle body 1; A hollow ring 11 is provided, and a pipe 12 that fits with the inner wall of the kettle body 1 is arranged on the hollow ring 11. A plurality of liquid outlet holes 13 are arranged on the pipe 12. The hollow ring 11 is connected with the suction pump 8. The liquid outlets 13 are connected. The liquid is pumped from the bottom of the kettle body through the pump, and then enters the pipe from the hollow ring, and enters...

Embodiment 2

[0022] A reaction kettle for liquid mixing, comprising a kettle body 1, an ear seat 2, an observation port 3, a feeding port 4, a material discharge port 5 and a heating pipe 6 are arranged on the kettle body 1, a stirring device 7 is arranged in the kettle body 1, and a stirring device 7 is arranged in the kettle body 1. The body 1 is provided with a liquid pump 8, the liquid inlet 9 of the liquid pump 8 is connected with the bottom of the kettle body 1, and the liquid outlet 10 of the liquid suction pump 8 is connected with the upper part of the kettle body 1; A hollow ring 11 is provided, and a pipe 12 that fits with the inner wall of the kettle body 1 is arranged on the hollow ring 11. A plurality of liquid outlet holes 13 are arranged on the pipe 12. The hollow ring 11 is connected with the suction pump 8. The liquid outlets 13 are connected. The liquid is pumped from the bottom of the kettle body through the pump, and then enters the pipe from the hollow ring, and enters...

Embodiment 3

[0024] A reaction kettle for liquid mixing, comprising a kettle body 1, an ear seat 2, an observation port 3, a feeding port 4, a material discharge port 5 and a heating pipe 6 are arranged on the kettle body 1, a stirring device 7 is arranged in the kettle body 1, and a stirring device 7 is arranged in the kettle body 1. The body 1 is provided with a liquid pump 8, the liquid inlet 9 of the liquid pump 8 is connected with the bottom of the kettle body 1, and the liquid outlet 10 of the liquid suction pump 8 is connected with the upper part of the kettle body 1; A hollow ring 11 is provided, and a pipe 12 that fits with the inner wall of the kettle body 1 is arranged on the hollow ring 11. A plurality of liquid outlet holes 13 are arranged on the pipe 12. The hollow ring 11 is connected with the suction pump 8. The liquid outlets 13 are connected. The liquid is pumped from the bottom of the kettle body through the pump, and then enters the pipe from the hollow ring, and enters...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com