Variable frequency paper shredder

A technology of paper shredders and variable frequency motors, applied in cleaning methods and utensils, grain processing, chemical instruments and methods, etc., can solve the problems of uneven paper sheets, low crushing efficiency, and reduced efficiency, and achieve simple device structure and recycling high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

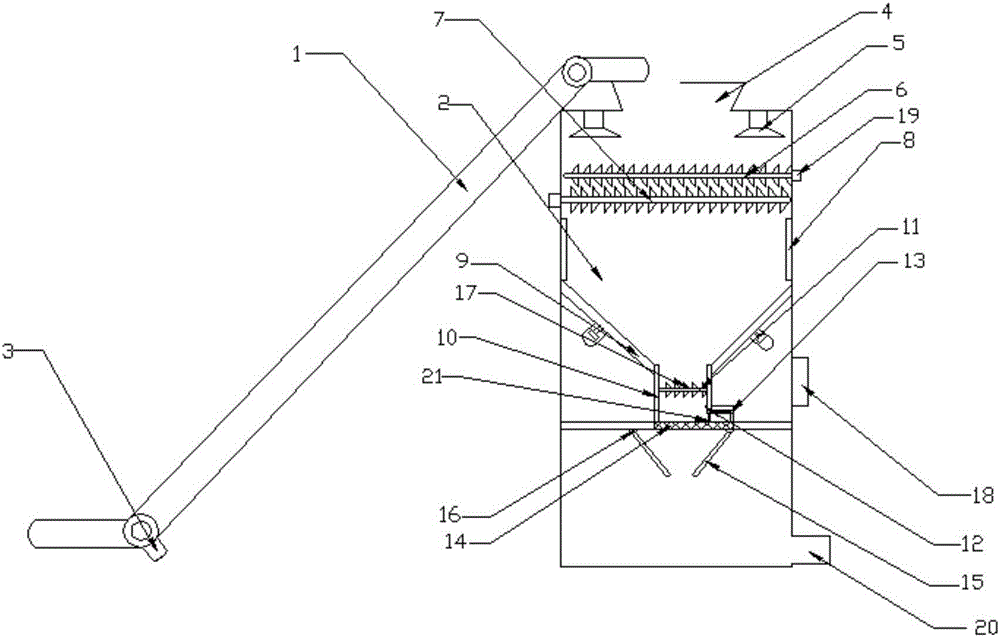

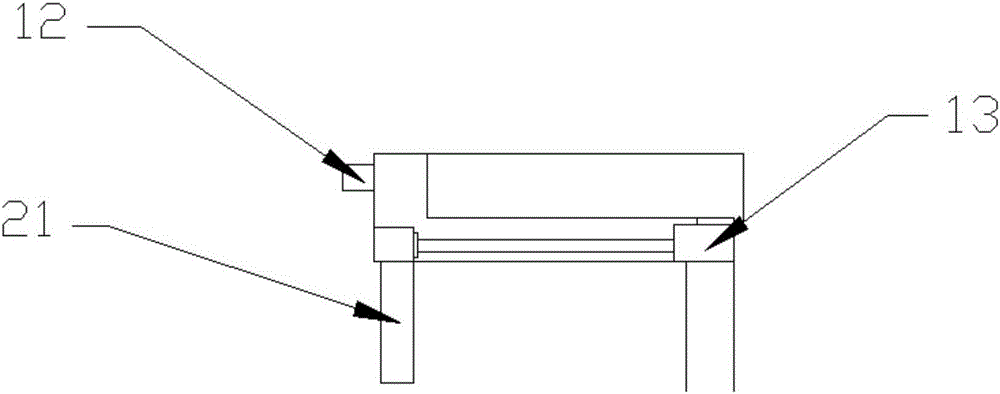

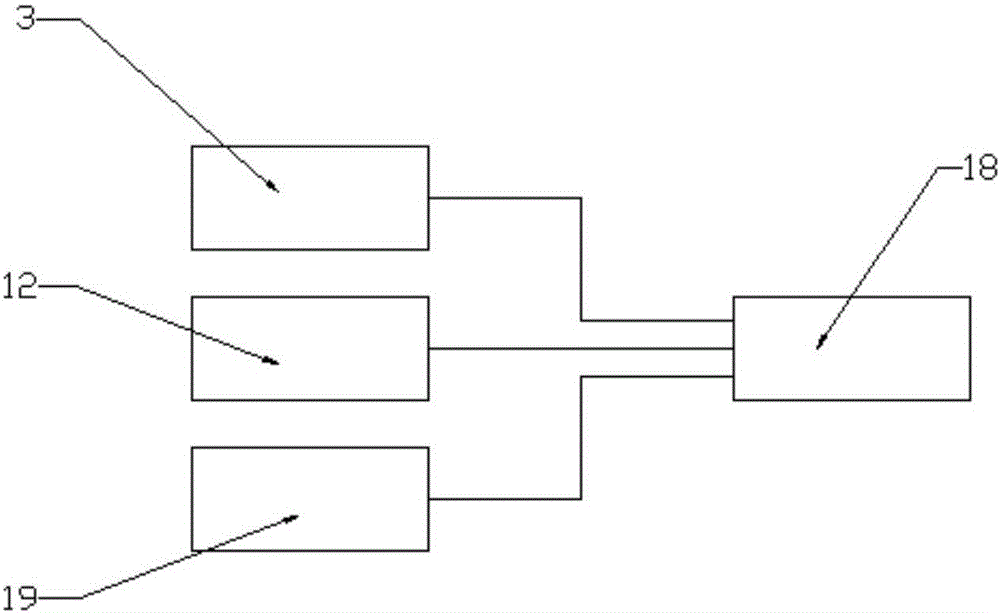

Embodiment 1

[0017] Such as Figure 1-3 As shown, a frequency conversion paper shredder of the present invention includes a conveyor belt 1, a shredder device 2 is provided at the bottom of the conveyor belt 1, a frequency conversion motor 3 is provided at the bottom of the conveyor belt 1, and a paper inlet 4 is provided at the top of the shredder 2 to crush The inside of the machine 2 is provided with a hot air blower 5, the bottom of the hot air blower 5 is provided with a first crushing roller 6, the bottom of the first crushing roller 6 is provided with a second crushing roller 7, and the bottom of the second crushing roller 7 is provided with a There is a vibrating plate 9, one end of the vibrating plate 9 is provided with a paper outlet 10, the inside of the paper outlet 10 is provided with a third pulverizing roller 11, the inner wall of the paper outlet 10 is provided with an inductor 12, one side of the inductor 12 A hydraulic expansion device 13 is provided, and one end of the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com