Novel multifunctional electrostatic powder spraying equipment

An electrostatic powder spraying and multi-functional technology, applied in the direction of electrostatic spraying device, spraying device, spray discharge device, etc., can solve the problems of inconvenient observation, single function, inconvenient operation, etc., and achieve the effect of simple structure, low noise and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

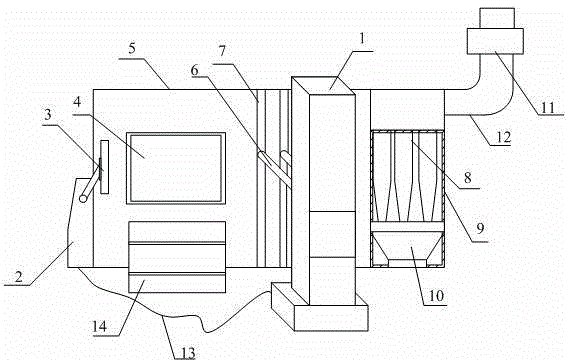

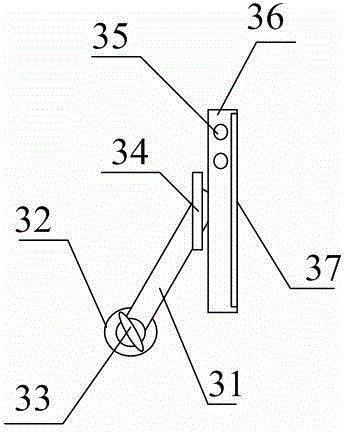

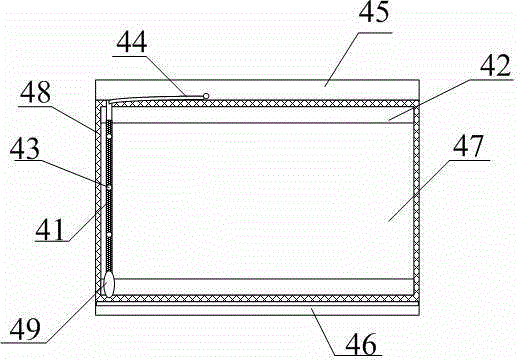

[0024] as attached figure 1 to attach image 3 shown

[0025] The present invention provides a new type of multifunctional electrostatic powder spraying equipment, which includes a lift 1, a control cabinet 2, an operation panel 3, an observation window 4, a spraying room 5, a spray gun 6, a guide groove 7, a recovery device 8, a bracket 9, and a recovery bucket 10 , filter 11, exhaust pipe 12, wire 13 and backing plate 14, described elevator 1 is connected with control cabinet 2 through wire 13; Described operation panel 3 is installed on the front side of control cabinet 2; Described observation The window 4 is installed on the front side of the spray booth 5; the spray gun 6 is installed on the rear side of the elevator 1; the spray gun 6 is fixed above the guide groove 7 of the spray booth 5; the recovery device 8 passes through the bracket 9 Installed on the right side of the spray booth 5; the recovery barrel 10 is fixed on the bottom of the recovery device 8; the filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com