Feeding device for biological waste treatment

A technology of feeding device and biological waste, which is applied to the removal of solid waste, conveyor objects, transportation and packaging, etc., can solve the problems of unfavorable human health, time-consuming and laborious handling, and easy inhalation of a large amount of garbage odor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

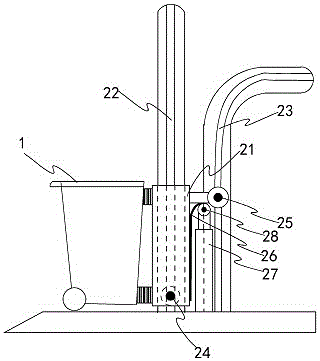

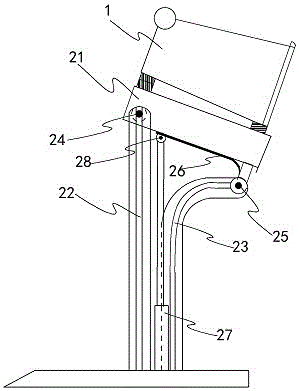

[0012] refer to Figure 1 to Figure 2 , the embodiment of the present invention discloses that a feeding device for biological waste treatment includes a trash can 1 and a shifting device 2, and the shifting device 2 includes a machine platform and a mobile platform 21 arranged in the machine platform, The machine platform is provided with two oppositely arranged front slideways 22 and two oppositely arranged rear slideways 23, the front slideway 22 is a vertical slideway, the rear slideway 23 is an inverted L-shaped slideway, and the front slideway 23 is an inverted L-shaped slideway. 22 is higher than the highest point of the rear slideway 23; the mobile platform 21 is located between the two front slideways 22, and the two sides of the mobile platform 21 are provided with front Slide bar 24, front slide bar 24 can slide along front slideway 22; D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com