Lifting type electric induction furnace with adjustable height

An induction furnace, adjustable technology, applied in the direction of furnace, crucible furnace, furnace type, etc., can solve the problems of induction furnace height unadjustable, inconvenient height, non-adjustable height, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

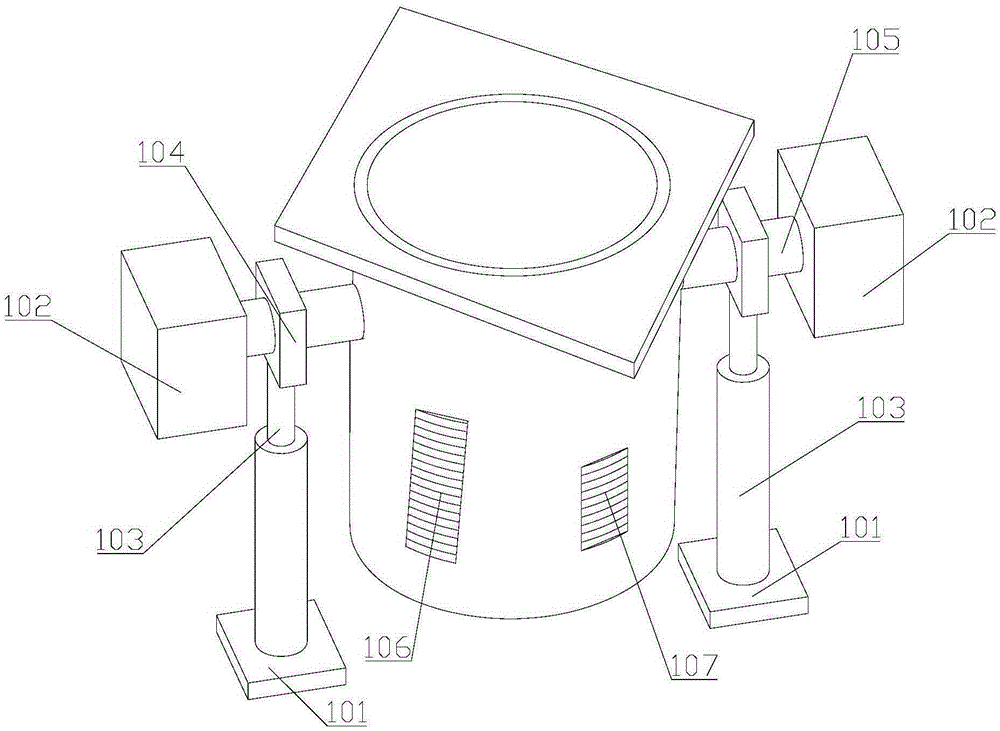

[0032] refer to figure 1 , this embodiment provides a height-adjustable lifting induction furnace, including: a furnace shell 201, an inner heating furnace and two lifting mechanisms, and the lifting structures are symmetrically arranged on both sides of the furnace shell 201. The inner heating furnace includes a heat-resistant inner lining, an induction coil 106 and a cooling pipe 107 . The inner heating furnace is arranged inside the furnace shell 201 , the induction coil 106 is wound outside the heat-resistant inner lining, and the water-cooled pipe is wound outside the induction coil 106 .

[0033]The lifting mechanism includes a base 101, a hydraulic rod 103, a rotating block 104, a rotating rod 105 and a driving assembly 102, and the driving assembly 102 includes a driving motor, a rotary encoder, a speed reducer and a PLC controller, and the PLC controller is electrically connected to the driving motor. The two ends of the hydraulic rod 103 are fixedly connected with th...

Embodiment 2

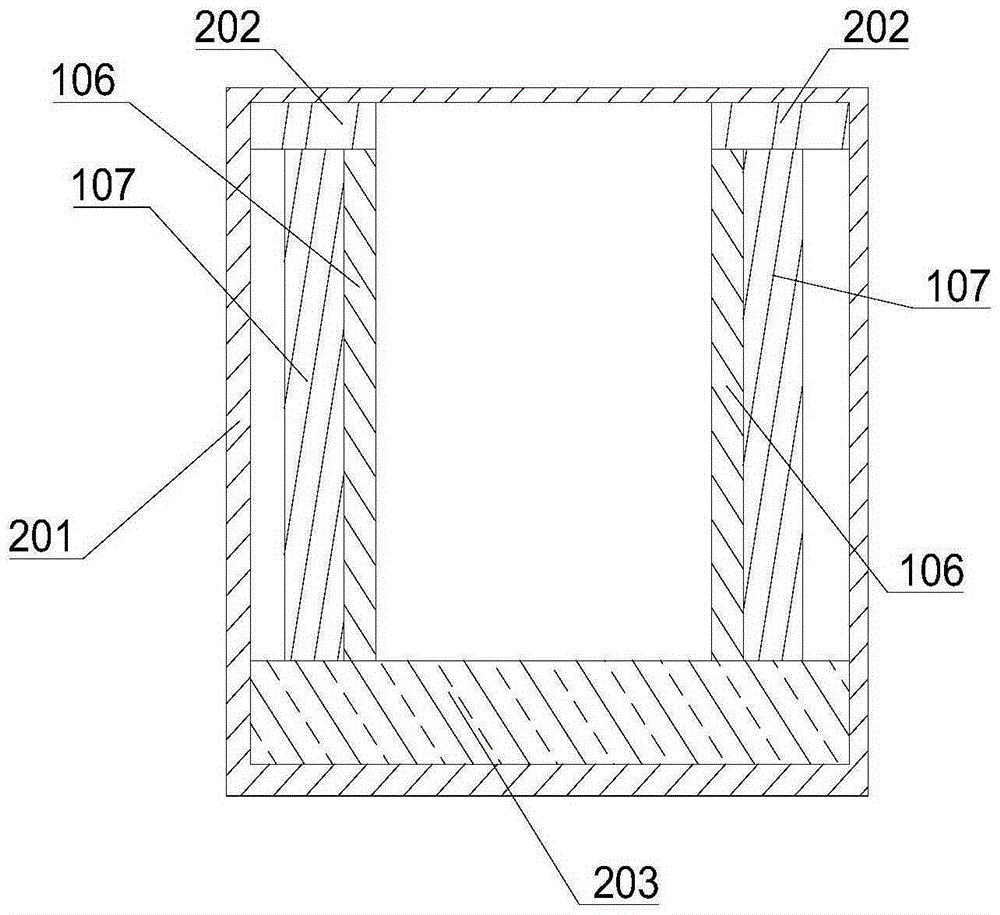

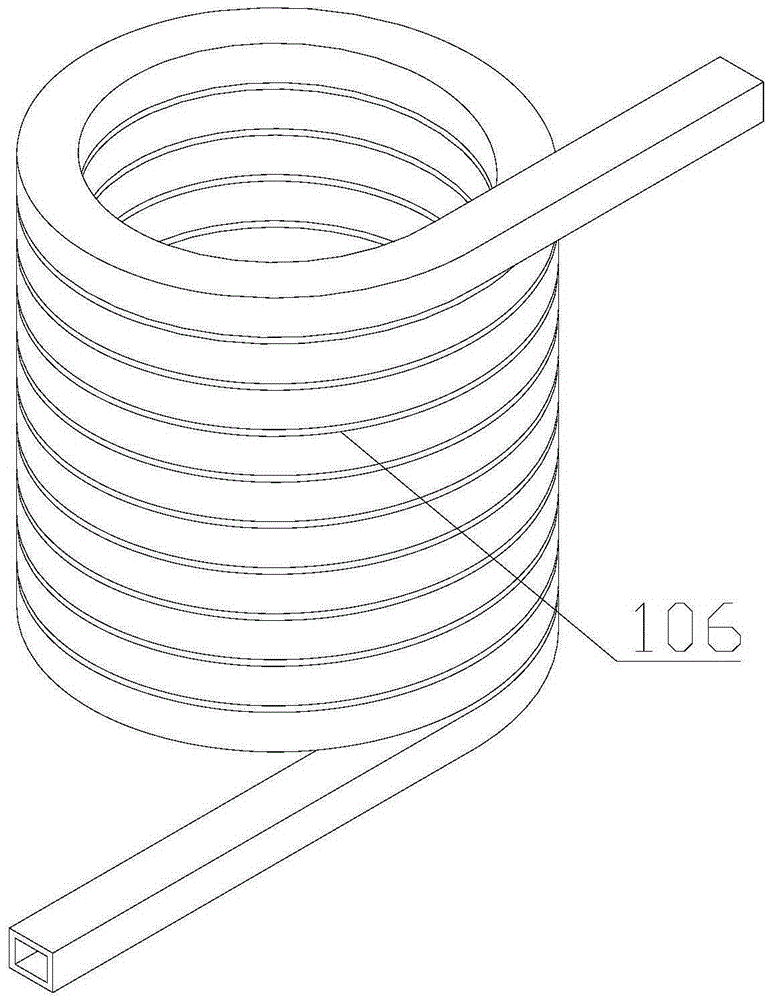

[0037] refer to figure 2 , image 3 , this embodiment provides a height-adjustable lifting induction furnace, including: a furnace shell 201, an inner heating furnace and two lifting mechanisms, and the lifting structures are symmetrically arranged on both sides of the furnace shell 201. The inner heating furnace includes a heat-resistant inner lining, an induction coil 106 and a cooling pipe 107 . The inner heating furnace is arranged inside the furnace shell 201 , the induction coil 106 is wound outside the heat-resistant inner lining, and the water-cooled pipe is wound outside the induction coil 106 . Preferably, the induction coil 106 is made of a square copper tube, and cooling water passes through the square copper tube. Cooling water is passed into the square copper tube to prevent the square copper tube from being damaged due to the impact of excessive temperature.

[0038] The lifting mechanism includes a base 101, a hydraulic rod 103, a rotating block 104, a rotat...

Embodiment 3

[0043] This embodiment provides a height-adjustable lift-type induction furnace, including: a furnace shell 201 , an inner heating furnace, and two lifting mechanisms. The lift structures are symmetrically arranged on both sides of the furnace shell 201 . The inner heating furnace includes a heat-resistant inner lining, an induction coil 106 and a cooling pipe 107 . The inner heating furnace is arranged inside the furnace shell 201 , the induction coil 106 is wound outside the heat-resistant inner lining, and the water-cooled pipe is wound outside the induction coil 106 .

[0044] The lifting mechanism includes a base 101, a hydraulic rod 103, a rotating block 104, a rotating rod 105 and a driving assembly 102, and the driving assembly 102 includes a driving motor, a rotary encoder, a speed reducer and a PLC controller, and the PLC controller is electrically connected to the driving motor. The two ends of the hydraulic rod 103 are fixedly connected with the base 101 and the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com