Dynamic specification-changing moving method for working rollers of cold continuous mill

A technology of dynamically changing specifications and cold tandem mills, applied in the field of rolling control, can solve problems such as broken strips, inability to ensure the control accuracy of the strip edges at the head and tail, and inability to ensure the set position of roll shifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] The present invention will be described in further detail below in conjunction with the accompanying drawings.

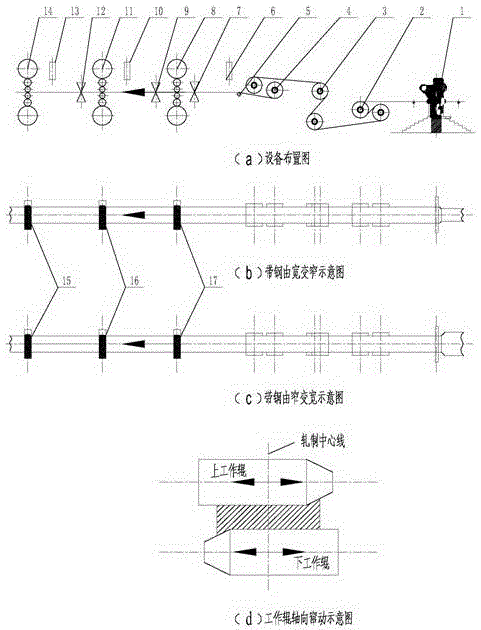

[0081] The present invention is suitable for single-ended tapered work roll traverse mills, see figure 1 . The first frame 8, the second frame 11, and the third frame 14 have the function of working lateral movement. The equipment includes entrance convexity meter 1, 5#S roller 2, deviation correction roller 3, 6#S roller 4, steering roller 5, the first rack entrance laser speed gauge 6, the first rack entrance thickness gauge 7, the first Thickness gauge 9 at the exit of the rack, laser speed gauge 10 at the entrance of the second rack, thickness gauge 12 at the exit of the second rack, and laser speed gauge 13 at the entrance of the third rack.

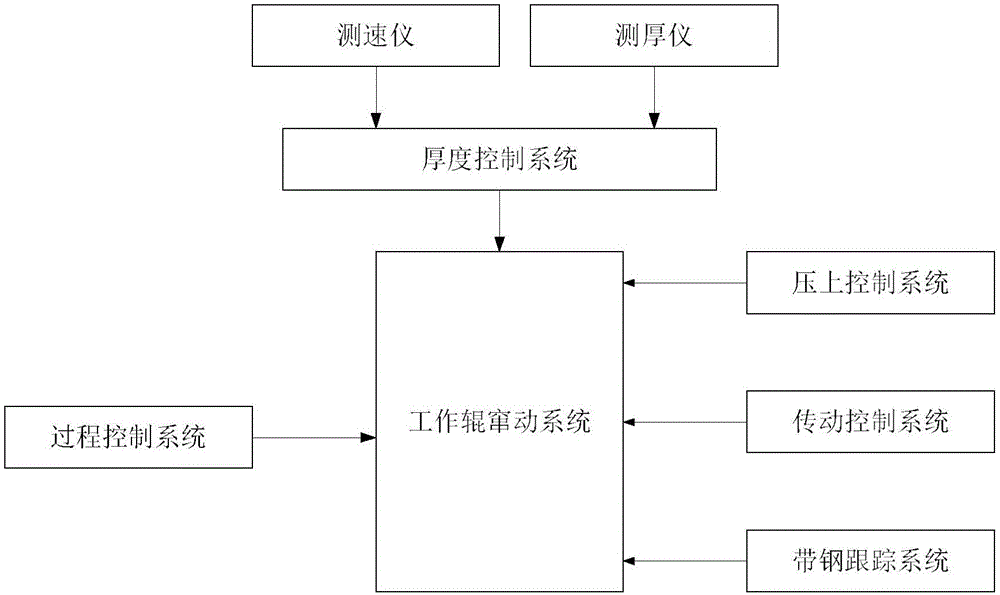

[0082] For the composition of the work roll movement control system, see figure 2 , including the work roll movement system (including the work roll dynamic change specification movement), process control syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com