Multifunctional drilling machine

A drilling machine, multi-functional technology, applied in the direction of boring/drilling, drilling/drilling equipment, metal processing machinery parts, etc., can solve the problems of inability to clean debris, single function, etc., to reduce equipment occupation effect of space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be described in further detail below by means of specific embodiments:

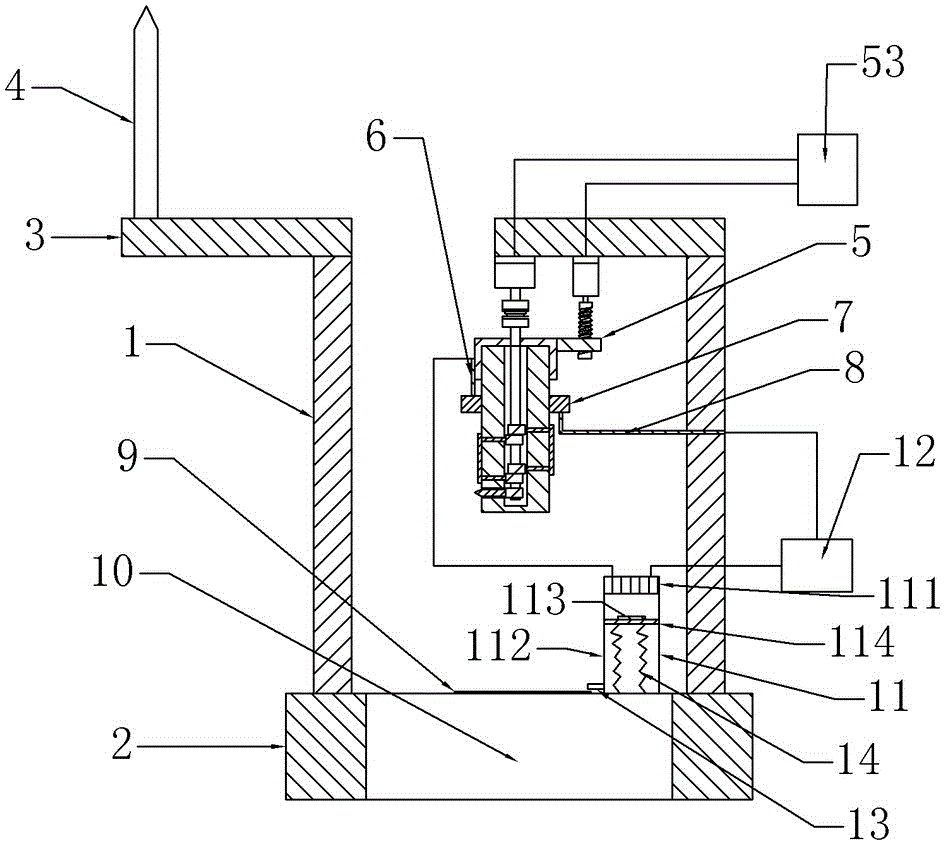

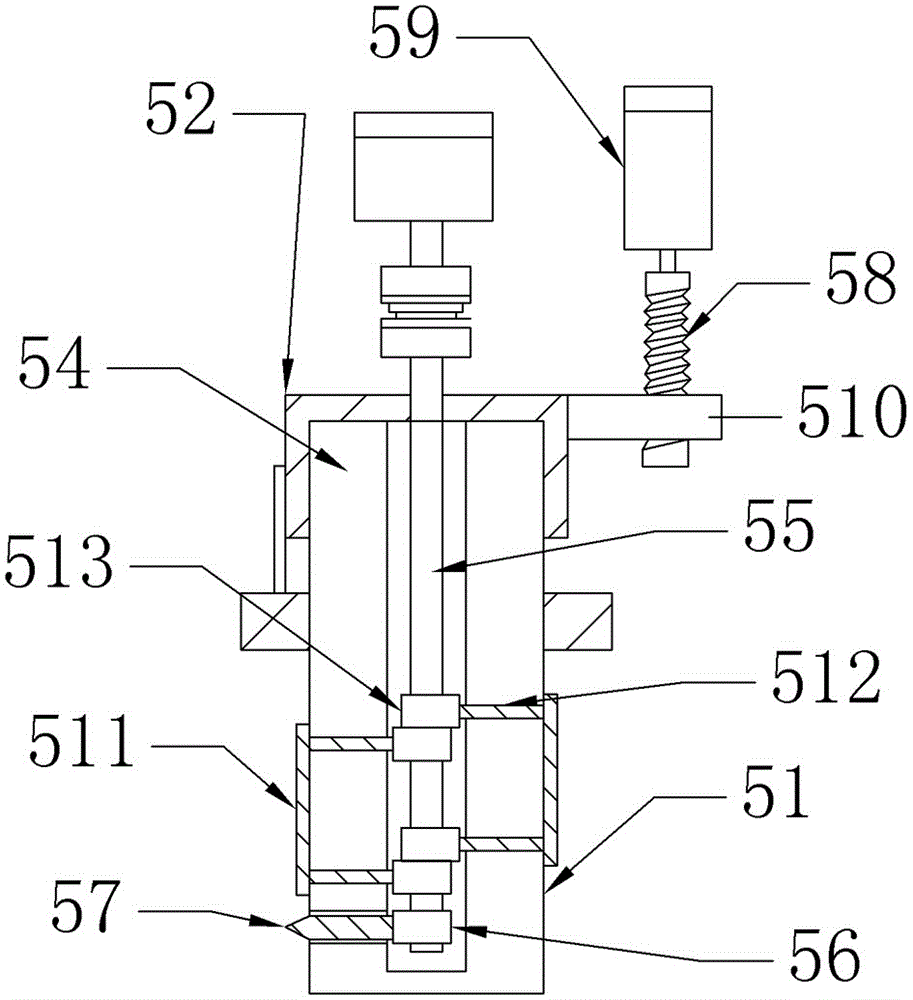

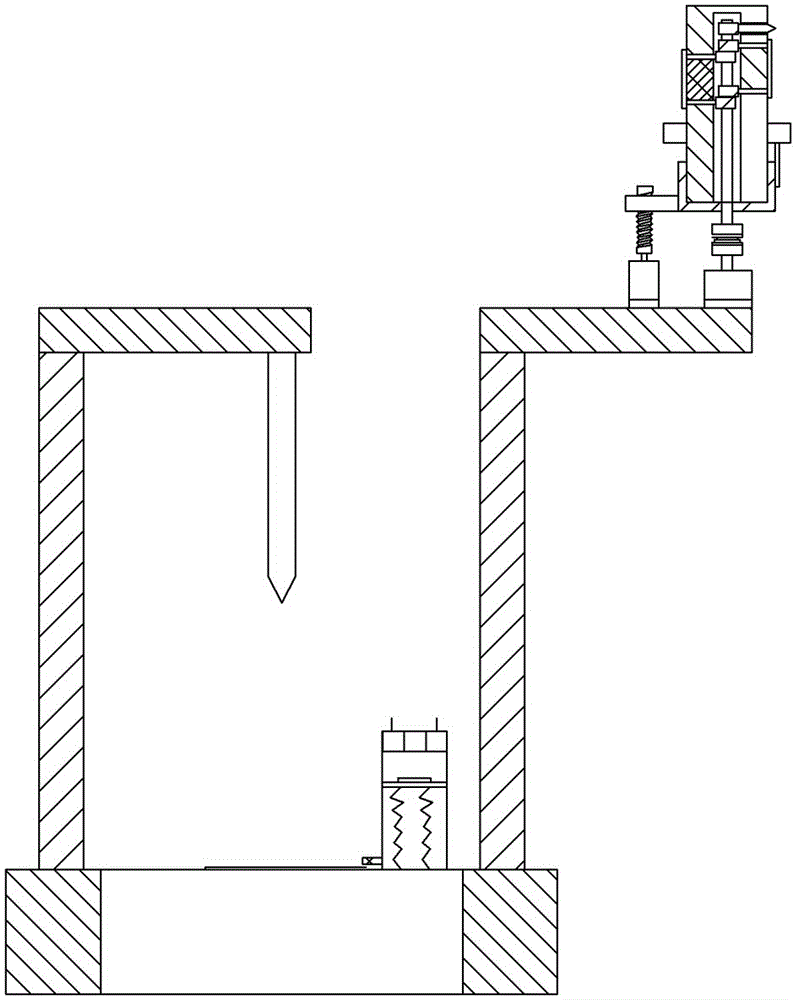

[0022] The reference signs in the drawings of the description include: frame 1, base 2, drilling machine 3, drill bit 4, boring machine 5, boring head 51, protective cover 52, control device 53, first rotating shaft 54, second rotating shaft 55, First cam 56, cutter 57, rotating shaft 58, motor 59, positioning block 510, grinding stone 511, column 512, second cam 513, first conductive member 6, conductive ring 7, insulating area 71, second conductive member 8 , workbench 9, hydraulic press 10, electromagnetic jet machine 11, electromagnetic coil 111, cylinder 112, iron sheet 113, pressing plate 114, power supply 12, jet pipe 13, extension spring 14.

[0023] Examples are attached figure 1As shown, the present invention provides a multifunctional drilling machine, which includes a frame 1 and a base 2 , wherein the base 2 is fixedly connected to the bottom of the frame 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com