Method for stretching main bolts of coolant pump of nuclear reactor

A coolant pump and nuclear reactor technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of increasing the collective dose value of overhaul, high labor intensity, and delaying the maintenance time of the main line, so as to reduce the collective dose value and alleviate Labor intensity, easy to implement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0023] A method for stretching main bolts of nuclear reactor coolant pumps provided by the present invention, taking the number of main bolts as 30 as an example, comprises the following steps:

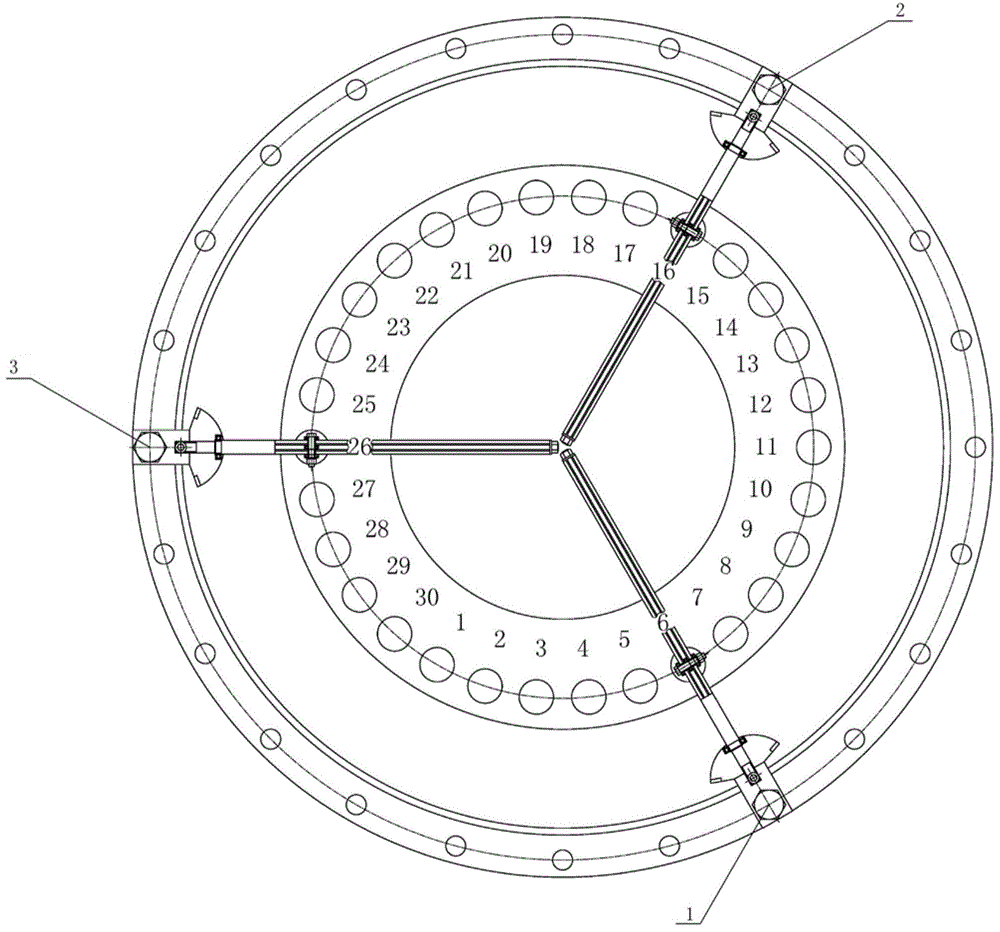

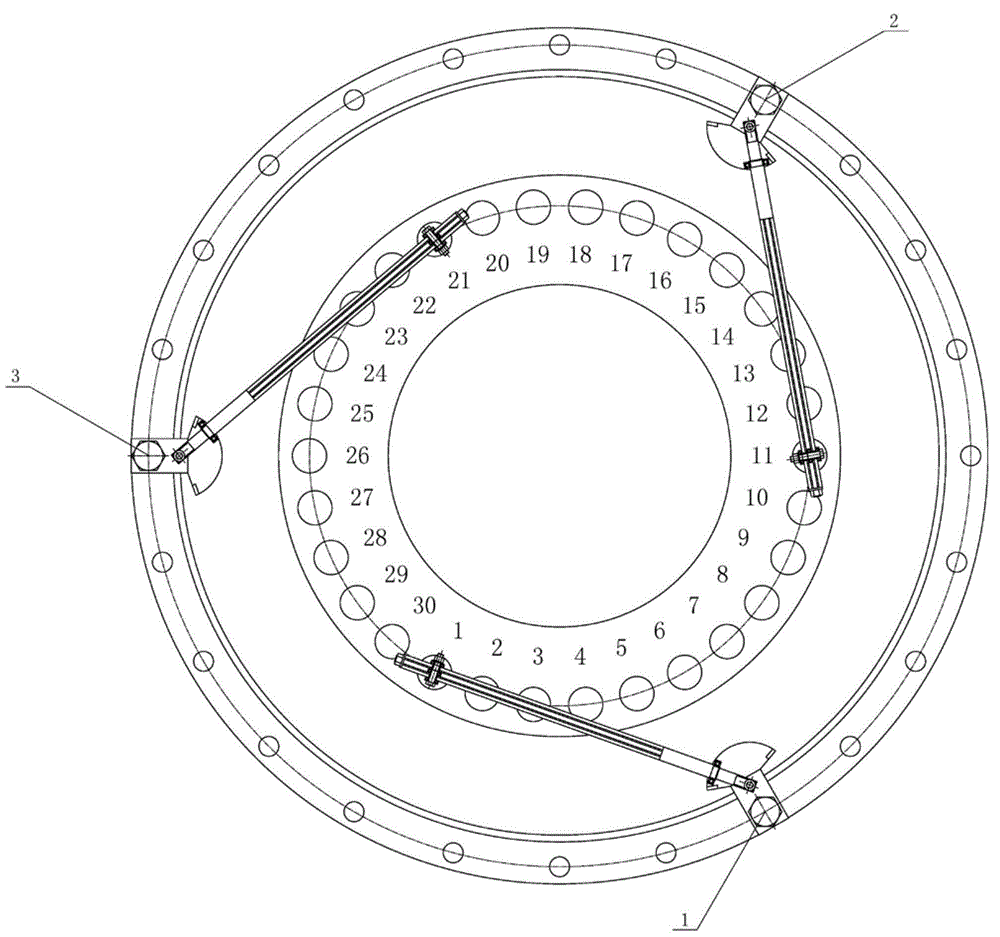

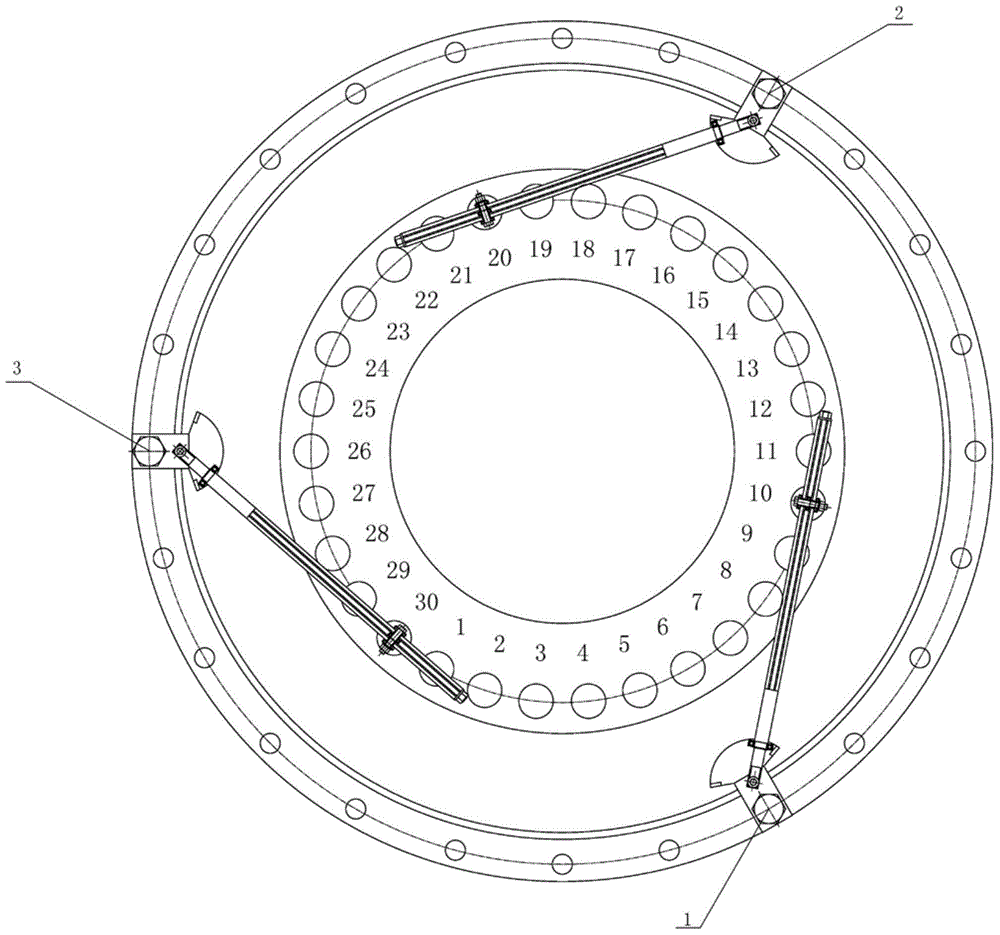

[0024] Such as figure 1 As shown, step 1. Number the 30 main bolts from 1 to 30 and mark them;

[0025] Such as figure 1 As shown, in step 2, install the No. 1 cantilever labor-saving manipulator 1 on the upper support frame corresponding to the No. 6 main bolt, and fasten it with fixing bolts; install the No. 2 cantilever labor-saving manipulator 2 on the No. 16 main bolt corresponding on the upper support frame of the upper support frame, and fasten it with fixing bolts; install the No.

[0026] Such as figure 1 As shown in step 3, install one end of the three bolt stretching cylinders on the shortcut grab hooks of No. 1 cantilever labor-saving manipulato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com