Vibration damping device for processing thin-wall axle part

A technology of vibration damping device and thin-walled shaft, which is applied in metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve problems such as difficulty in guaranteeing dimensional accuracy and surface quality, inability to meet the needs of mass production of parts, and pollution of the environment, etc. Achieve the effect of light weight, compact structure and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

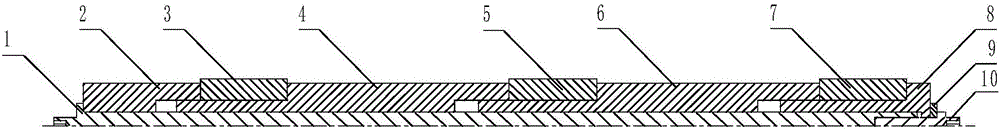

[0039] There are 4 plastic rings in total, including the first plastic ring 2, the second plastic ring 4, the third plastic ring 6 and the fourth plastic ring 8. The outer diameter of each plastic ring is the same, which is Φ75mm;

[0040] The diameter of the inner hole of the first plastic ring 2 is Φ25mm, and an inner hole step with a diameter of Φ45mm and a depth of 80mm is opened at one end thereof;

[0041] The size and structure of the second plastic ring 4 and the third plastic ring 6 are the same, the diameter of the inner hole is Φ25mm, one end has a shaft with a diameter of Φ45mm, and the other end has an inner hole step with a diameter of Φ45mm and a depth of 80mm;

[0042] The diameter of the inner hole of the fourth plastic ring 8 is Φ25mm, a shaft with a diameter of Φ45mm is opened at one end, and an inner hole with a diameter of Φ16mm is opened at the other end;

[0043] There are 3 rubber rings, including the first rubber ring 3, the second rubber ring 5 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com