Industrial steel surface polishing machine

A surface polishing and steel technology, applied in the field of polishing machines, can solve the problems of high cost and small application range, and achieve the effects of increasing friction coefficient, prolonging service life and improving polishing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

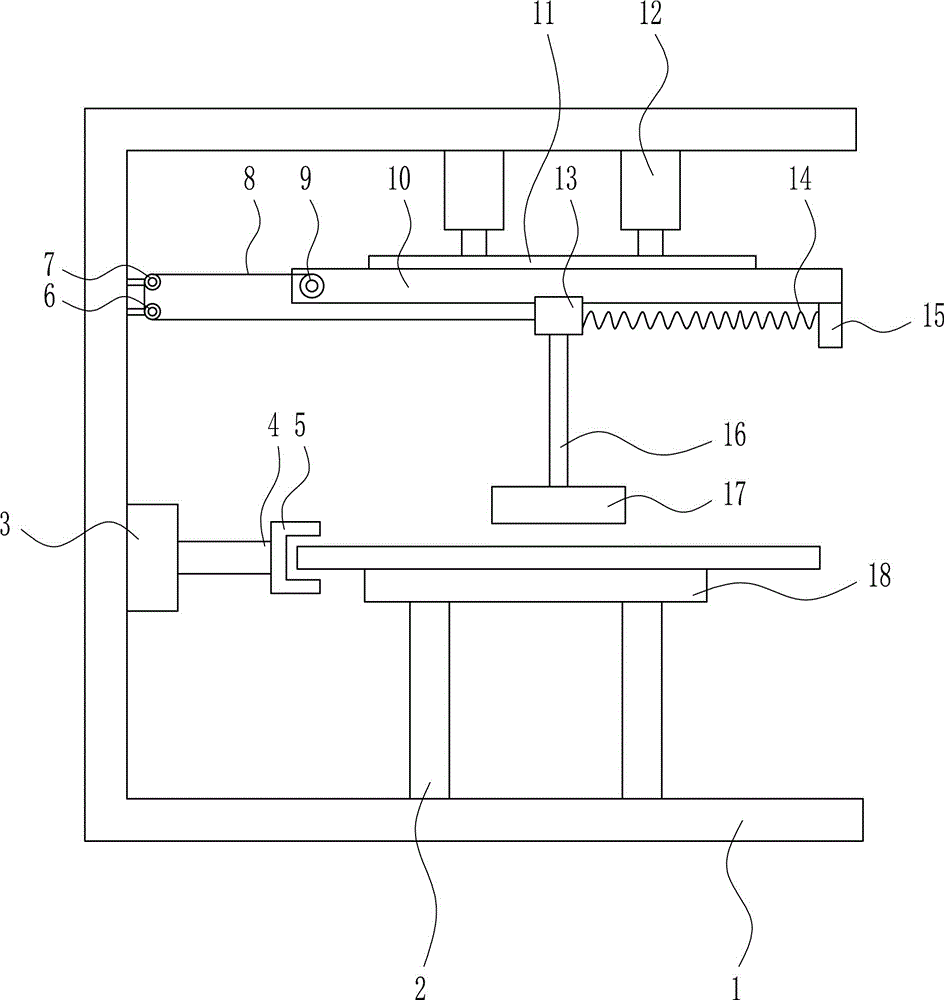

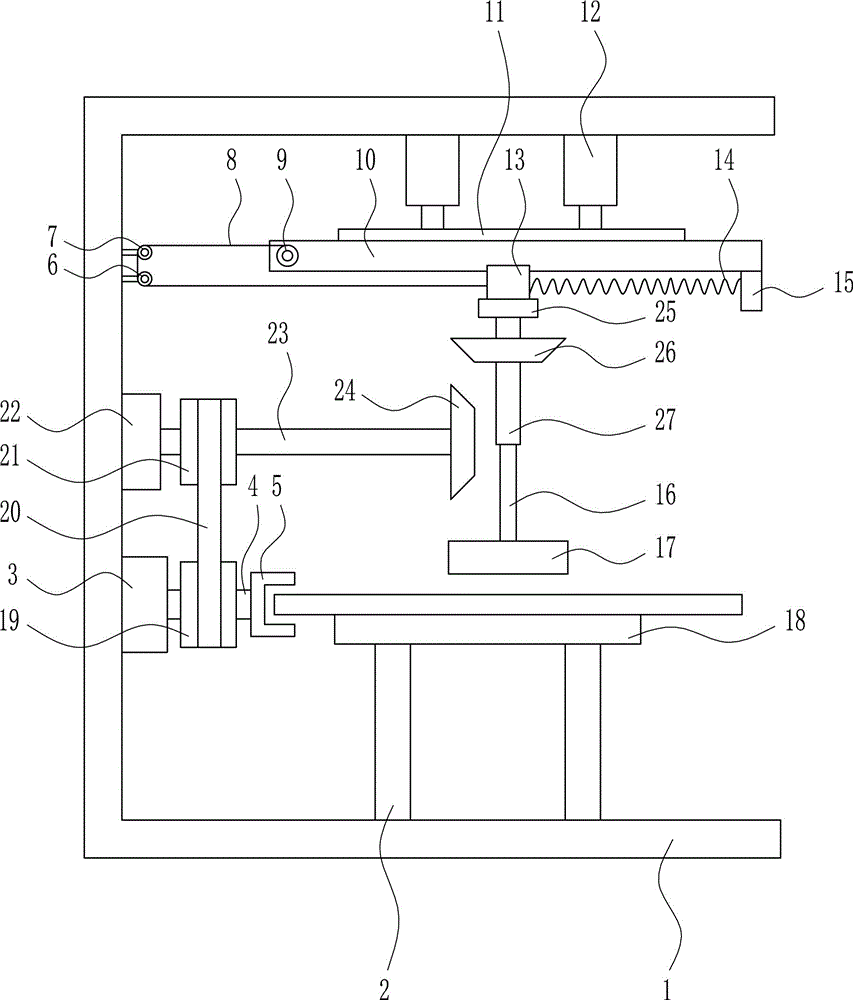

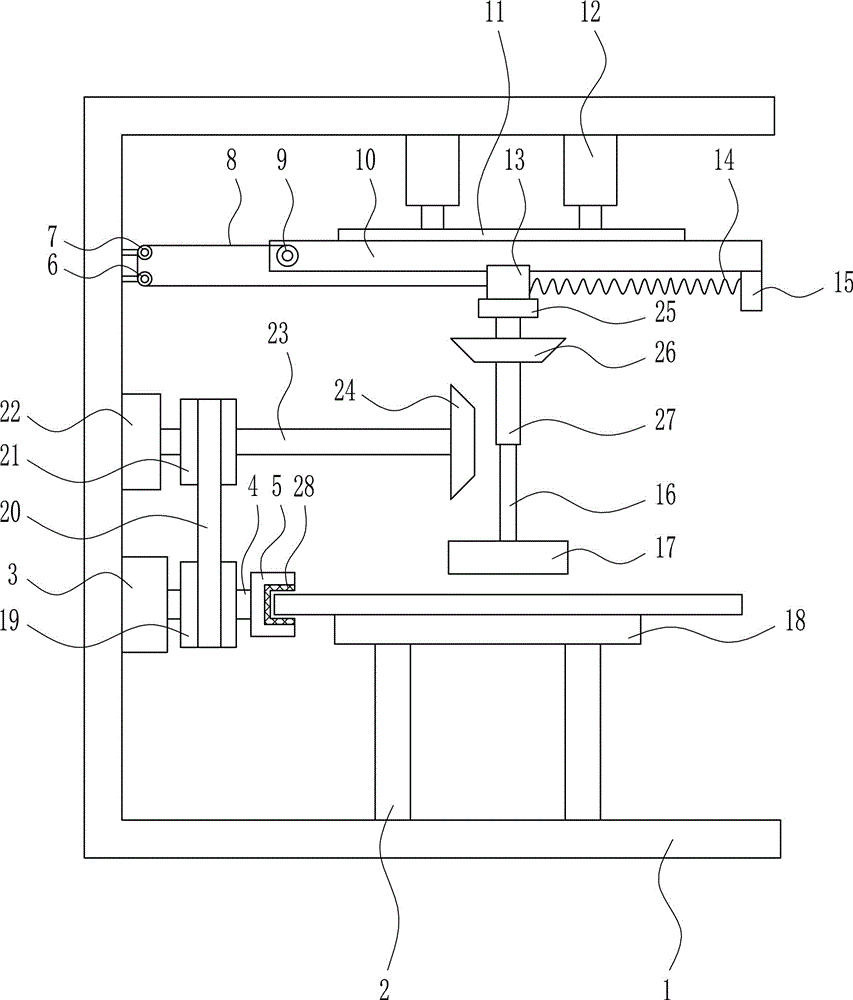

[0031] An industrial steel surface polishing machine, such as Figure 1-5 As shown, it includes a bracket 1, a support rod 2, a rotating motor 3, a first rotating shaft 4, a thumb cylinder 5, a first fixed pulley 6, a second fixed pulley 7, a pull cord 8, an electric reel 9, and a slide rail 10 , support plate 11, first cylinder 12, slider 13, elastic element 14, baffle plate 15, connecting rod 16, millstone 17 and placement plate 18; the center and right side of the inner bottom of the bracket 1 are connected with supports by welding Rod 2, the top of the support rod 2 is connected with the placement plate 18 by bolt connection, the rotating motor 3 is connected with the bottom left wall of the bracket 1 by bolt connection, and the output shaft of the rotating motor 3 is connected with the first rotating shaft through a coupling 4. The right end of the first rotating shaft 4 is connected with the thumb cylinder 5 by means of bolt connection, the first fixed pulley 6 is welded...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com