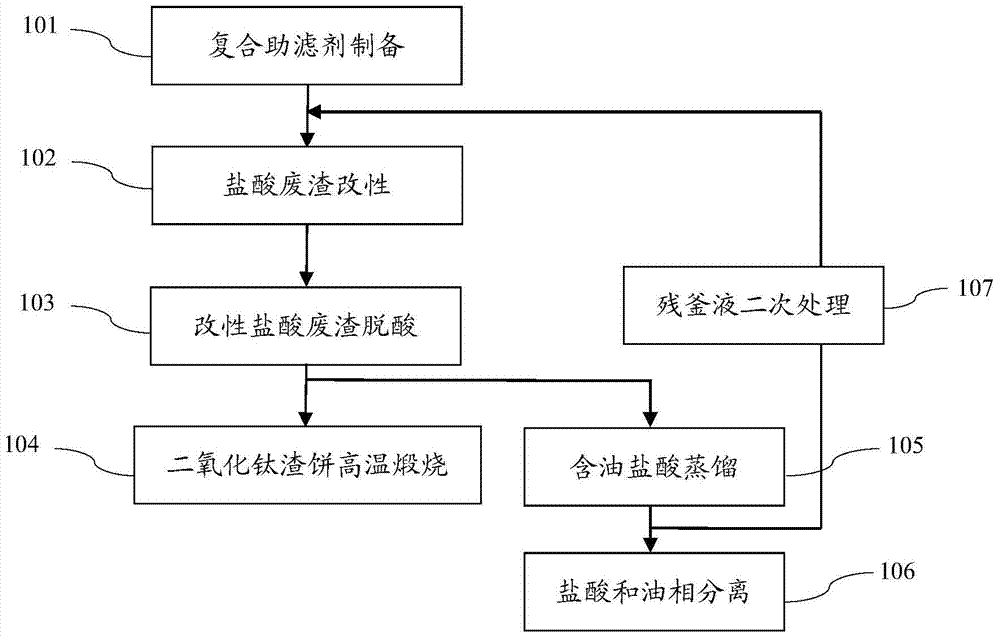

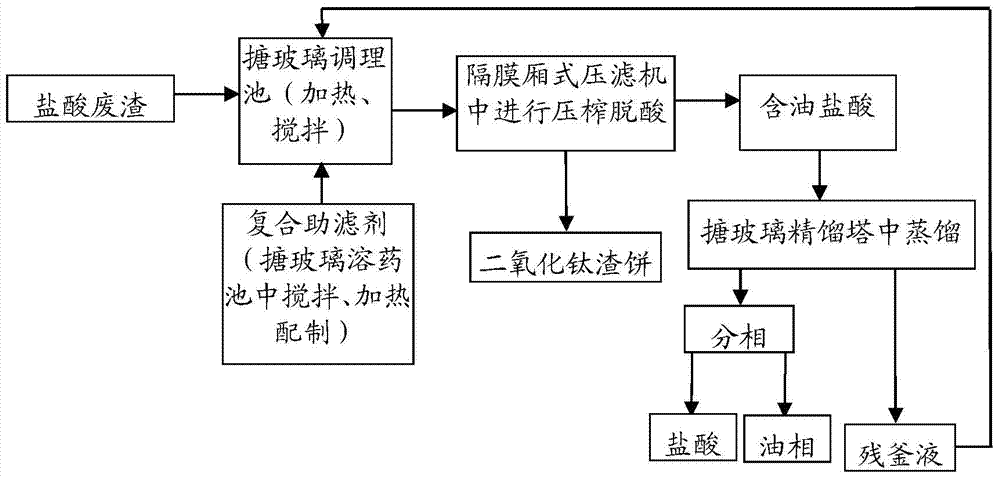

A kind of process of resource recovery and utilization of titanium dioxide hydrochloric acid waste residue

A titanium dioxide and resource recovery technology, applied in the field of environmental engineering, can solve the problems of narrow range of auxiliary/flocculant and little effect, and achieve the effect of convenient procurement and configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The first part, the modification of compound filter aid to the filtration and deacidification performance of hydrochloric acid waste residue (small test of filter press).

[0052] The filter area is 0.16m 2 The 250-type chamber filter press was used to compare the deacidification effect of the modified hydrochloric acid waste residue. The specific test steps, methods and parameters are adjusted as follows:

[0053] Dissolving polyethylene glycol, polyvinylpyrrolidone and polyvinyl alcohol successively in a glass-lined drug dissolution pool containing tap water in a mass ratio of 1:2:7 to obtain a strong acid-resistant composite filter aid with a mass concentration of 2%;

[0054] Pre-dissolved in hot water at 90-95°C to obtain a 2% volume concentration composite filter aid solution;

[0055] Take some DQ, BCE, N series catalyst hydrochloric acid waste residues, add composite filter aid according to 25% of its volume for conditioning, add slowly while stirring, continu...

Embodiment 2

[0069] The filter area is 0.16m 2 The 250-type chamber filter press was used to compare the deacidification effect of the modified hydrochloric acid waste residue. The specific test steps, methods and parameters are adjusted as follows:

[0070] Dissolving polyethylene glycol, polyvinylpyrrolidone and polyvinyl alcohol successively in a glass-lined drug dissolution pool containing tap water in a mass ratio of 2:3:5 to obtain a strong acid-resistant composite filter aid with a mass concentration of 2%;

[0071] Pre-dissolved in hot water at 90-95°C to obtain a 2% mass concentration composite filter aid solution;

[0072] Take some DQ, BCE, N series catalyst hydrochloric acid waste residues, add composite filter aid according to 30% of its volume for conditioning, the reaction is carried out in the glass-lined conditioning tank, add slowly while stirring, continue stirring for 30 minutes after the addition is completed, so that The system is mixed evenly, and then the feed is ...

Embodiment 3

[0076] The filter area is 0.16m 2 The 250-type chamber filter press was used to compare the deacidification effect of the modified hydrochloric acid waste residue. The specific test steps, methods and parameters are adjusted as follows:

[0077] Dissolving polyethylene glycol, polyvinylpyrrolidone and polyvinyl alcohol successively in a glass-lined drug dissolution pool containing tap water in a mass ratio of 11:19:42 to obtain a strong acid-resistant composite filter aid with a mass concentration of 2%;

[0078] Pre-dissolved in hot water at 90-95°C to obtain a 2% volume concentration composite filter aid solution;

[0079] Take some DQ, BCE, N catalyst hydrochloric acid waste residue, add composite filter aid according to 20% of its volume for conditioning, add slowly while stirring, continue stirring for 25 minutes after adding, make the system evenly mixed, and then use a filter press to filter Material deacidification;

[0080] Filter press operating parameters: The pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com