Fire extinguishment tape

A technology of fire extinguishing belt and quality, applied in the field of fire extinguishing belt, can solve problems such as loss, and achieve the effect of reducing damage, large social and economic effects, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

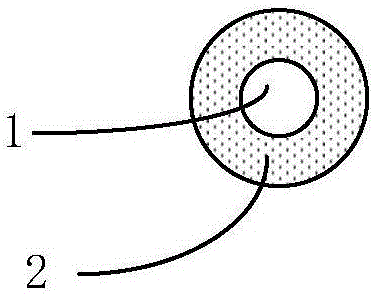

[0017] The fire extinguishing belt provided by the present invention will be further described below.

[0018] The invention provides a fire extinguishing belt. The material of the fire extinguishing belt includes a base material, graphene and expandable graphite, and the graphene and expandable graphite are evenly distributed in the base material.

[0019] The mass of the graphene is 0.000005% to 10% of the mass of the substrate, preferably 0.0002% to 10%. The mass of the expandable graphite is 30%-200% of the mass of the substrate, preferably 50%-200%.

[0020] The expandable graphite is to insert interlayer inserts, such as sulfuric acid molecules, water molecules, etc., between graphite layers by physical or chemical means, while still maintaining a graphite layered structure. When the expandable graphite is heated, such as above 150 degrees Celsius, due to the expansion force generated by the decomposition or vaporization of interlayer inserts, the expansion force is mu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com