A low temperature liquid phase sintering forming method of mixed metal fiber sintered felt

A technology of fiber sintered felt and mixed metal, which is applied in metal processing equipment, coating, transportation and packaging, etc. It can solve the problems of complex porous metal fiber carrier board technology, and achieve small deformation, low sintering temperature and high mechanical strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] In this embodiment, copper and aluminum are used as metals to make metal fibers. Copper fibers and aluminum fibers can be manufactured by using a special multi-tooth tool to turn copper rods and aluminum rods on an ordinary lathe. The surface of the metal fiber processed by this method has a rich microstructure, and the equivalent diameter is 50-100 μm. In particular, copper fibers with a diameter of 60 μm and aluminum fibers with a diameter of 50 μm are used in this embodiment. Then, cut the metal fiber into appropriate small sections, the length is about 15-20mm, especially, the present embodiment uses 20mm, and coats a layer of zinc / tin layer with a thickness of 5 μm on the surface of the aluminum fiber, and mixes the copper fiber and the aluminum fiber evenly Pressed into a mixed metal fiber sintered mat with a predetermined porosity.

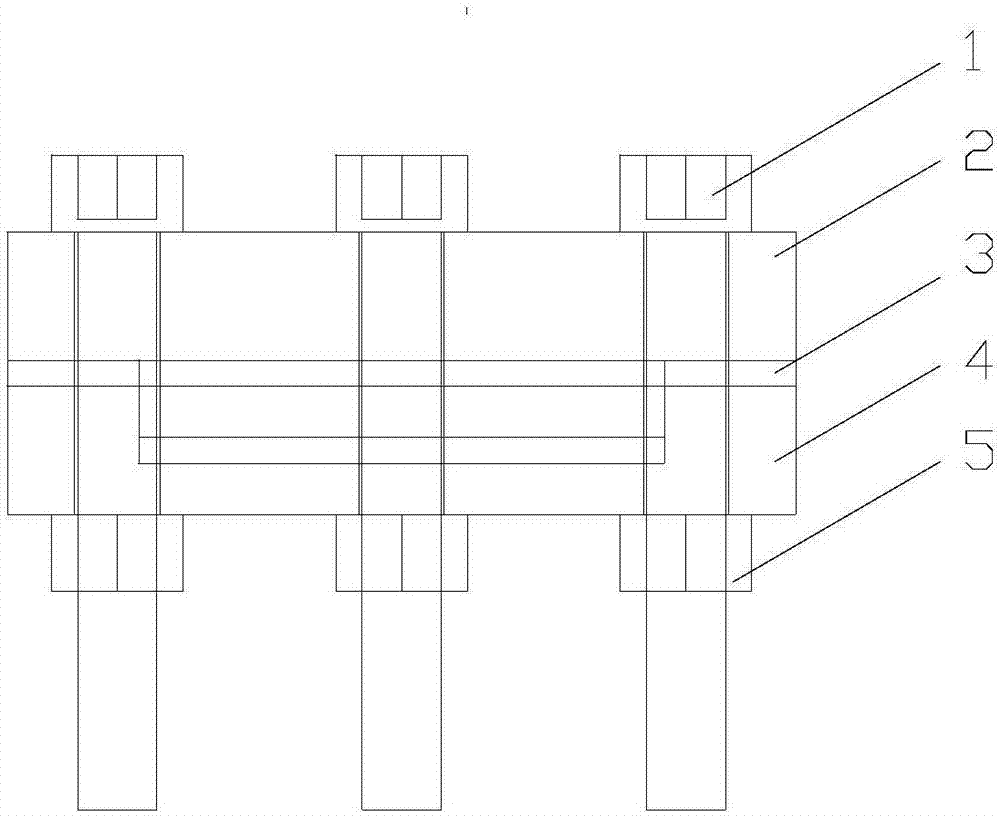

[0028] The present invention designs and manufactures a special abrasive tool for preparing mixed metal fiber sintered felt by low-...

Embodiment 2

[0031]In this embodiment, stainless steel and copper are used as metals to make metal fibers, and the metal fiber processing method and abrasive molding method are the same as those in Embodiment 1. Use stainless steel fibers and copper fibers to cut into small sections with a length of 20 mm and a diameter of 60 μm to make a mixed metal fiber sintered felt with a porosity of 80% and a thickness of 2 mm. Put the above-mentioned abrasive tools into a sintering furnace for sintering at a temperature of 210 ° C , When the holding time is 30min, nitrogen is used as a protective gas at the same time. After the holding time is over, let it cool down to room temperature with the furnace, and finally take out the abrasive tool and disassemble the abrasive tool to obtain a mixed metal fiber sintered felt.

Embodiment 3

[0033] In this embodiment, stainless steel and aluminum are used as metals to make metal fibers, and the metal fiber processing method and abrasive molding method are the same as those in Embodiment 1. Use stainless steel fibers and aluminum fibers to cut into small sections with a length of 20 mm and a diameter of 60 μm to make a mixed metal fiber sintered felt with a porosity of 90% and a thickness of 2 mm. Put the above-mentioned abrasive tools into a sintering furnace for sintering at a temperature of 220 ° C , When the holding time is 30min, nitrogen is used as a protective gas at the same time. After the holding time is over, let it cool down to room temperature with the furnace, and finally take out the abrasive tool and disassemble the abrasive tool to obtain a mixed metal fiber sintered felt.

[0034] The invention discloses a low-temperature liquid-phase sintering forming method of a mixed metal fiber sintered felt. The manufacturing process of mixed metal fiber sin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com