Device and method for magnetically induced vibration solidification of light alloy melt

A light alloy and melt technology, applied in the field of light alloy melt magneto-vibration solidification devices, can solve the problems of composition segregation, unevenness, coarse grain structure, etc. The effect of refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

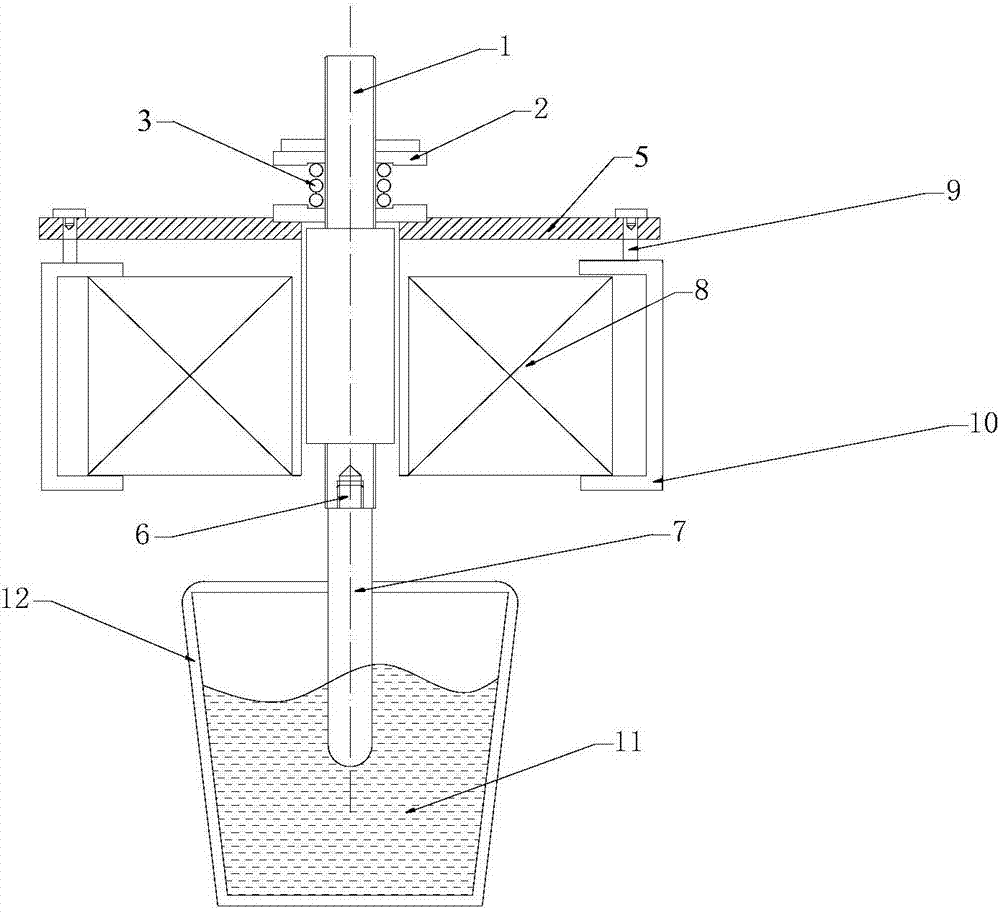

[0065] A device A for magnetically induced vibratory solidification of a light alloy melt, comprising a vibrating rod, a fixed frame cover 5 and an induced magnetic field generating system 8; the vibrating rod is a stepped rod, and the thin end of the stepped rod passes through the fixed frame cover 5, and the fixed The thin end of the ladder rod on the top of the cover plate 5 is provided with a spring pressing piece 2, and a spring 3 is arranged between the spring pressing piece 2 and the fixed frame cover plate 5; An induction magnetic field generation system 8 is arranged on the outer circumferential side of the upper part of the vibrating rod, and the vibrating rod provides vibration driving force through the induction magnetic field generating system 8 .

[0066] The vibrating rod adopts a split structure, which is divided into an upper vibrating rod 1 and a lower vibrating rod 7 , and the upper vibrating rod 1 and the lower vibrating rod 7 are connected by a threaded str...

Embodiment 2

[0088] A device A for magnetically induced vibratory solidification of a light alloy melt, comprising a vibrating rod, a fixed frame cover 5 and an induced magnetic field generating system 8; the vibrating rod is a stepped rod, and the thin end of the stepped rod passes through the fixed frame cover 5, and the fixed The thin end of the ladder rod on the top of the cover plate 5 is provided with a spring pressing piece 2, and a spring 3 is arranged between the spring pressing piece 2 and the fixed frame cover plate 5; An induction magnetic field generation system 8 is arranged on the outer circumferential side of the upper part of the vibrating rod, and the vibrating rod provides vibration driving force through the induction magnetic field generating system 8 .

[0089] The vibrating rod adopts a split structure, which is divided into an upper vibrating rod 1 and a lower vibrating rod 7, and the upper vibrating rod 1 and the lower vibrating rod 7 are connected by a fixed pin.

...

Embodiment 3

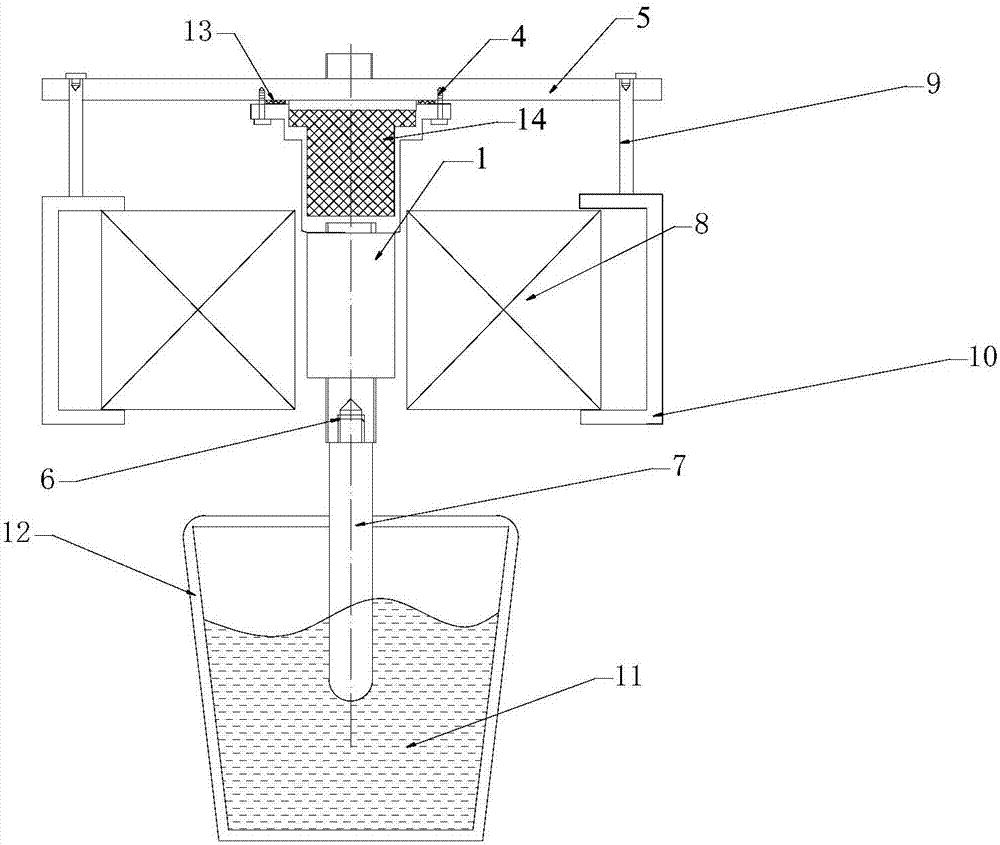

[0108]A device B for magnetically induced vibration solidification of light alloy melts, comprising a vibrating rod, a fixed frame cover plate 5 and an induced magnetic field generating system 8; the vibrating rod is a stepped rod, and the upper end of the vibrating rod is provided with a permanent magnet 14 with a The vibrating bar of 14 is hung on the lower surface of fixed mount cover plate 5.

[0109] The upper end of the vibrating rod with permanent magnet 14 is provided with a flange structure 4, and one end of the permanent magnet 14 of the vibrating rod is fixed on the lower surface of the fixed frame cover plate 5 by bolts, and the vibrating rod of the permanent magnet 14 and the fixed frame cover plate 8 A rubber gasket 13 is arranged between, and the part of the bolt corresponding to the cover plate of the fixed frame is a threaded structure, and the part of the bolt corresponding to the rubber gasket and the vibrating rod is a polished rod.

[0110] An induced magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com