Centralized curing device and curing method for carbon-fiber-wound hydrogen storage tanks

A curing device and carbon fiber technology, which is applied to hollow objects, other household appliances, household appliances, etc., can solve the problems of large amount of hot air consumption, poor uniformity of hot air, high energy consumption, etc., to achieve improved performance and quality, small amount of hot air consumption, and energy saving effects Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

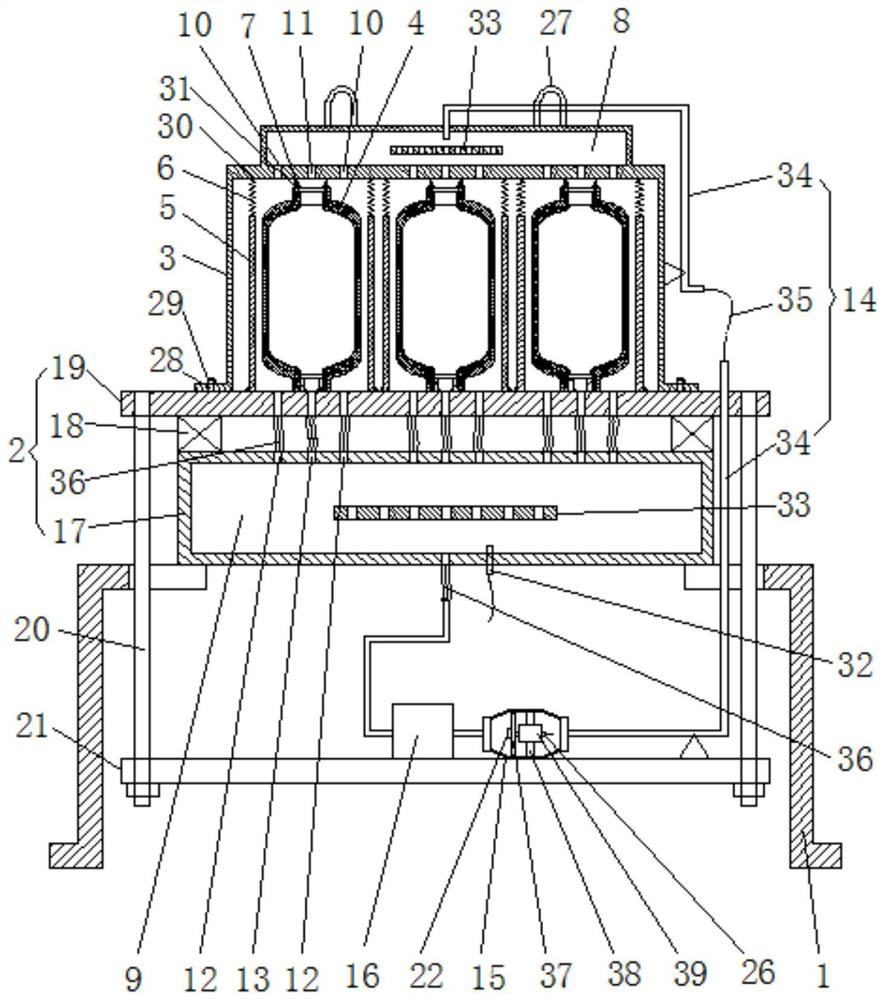

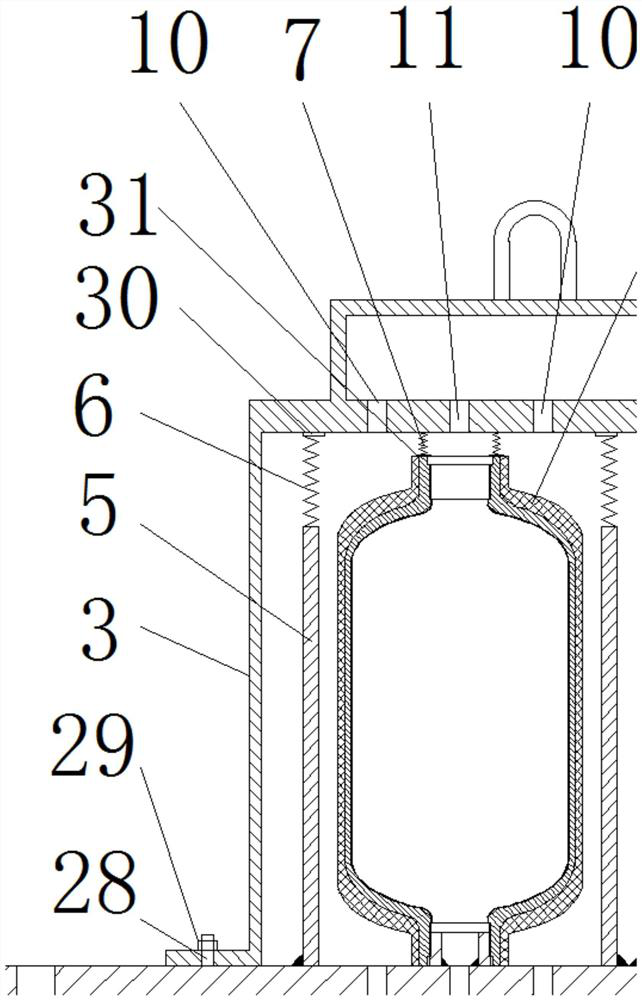

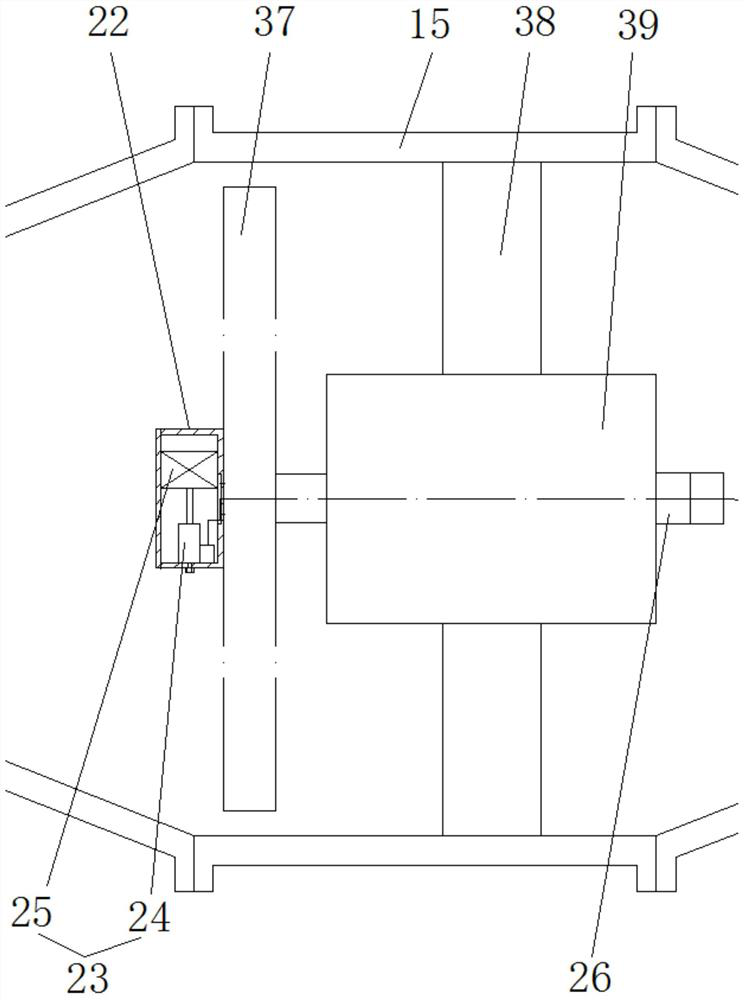

[0047] like Figures 1 to 3 Shown is an embodiment of a centralized curing device for a carbon fiber wound hydrogen storage tank of the present invention, including a frame 1, a frame platform 2 arranged at the upper end of the frame 1, and a frame platform 2 arranged above the frame platform 2. A platform cover 3 for covering the frame platform 2, on the frame platform 2 and below the platform cover 3, a number of carbon fiber wound hydrogen storage tanks 4 distributed in arrays are vertically installed , and a vertical sheath 5 is arranged on the periphery of each carbon fiber wound hydrogen storage tank 4 on the frame platform 2, and the upper end opening of the vertical sheath 5 is connected with a first bellows 6, the The lower end of the platform cover 3 is provided with a second bellows 7 facing the mouth of the carbon fiber wound hydrogen storage tank 4, and the upper end of the first bellows 7 elastically leans against the lower end of the platform cover 3. The lower...

Embodiment 2

[0063] A kind of curing method adopting the centralized curing device of the carbon fiber winding hydrogen storage tank of embodiment 1, comprises the steps:

[0064] (1) Workpiece installation: Open the platform cover 3 by hoisting, install the carbon fiber wound hydrogen storage tank 4 on the rack platform 2, and reclose the platform cover 3 after installation;

[0065] (2) Preheating: Turn on the fan 15 and the air heater 16 through the control system to heat up the circulating hot air to the preheating temperature;

[0066] (3) heating up: the circulating hot air is slowly warmed up to a predetermined curing temperature by the air heater 16;

[0067] (4) heat preservation: heat up to the predetermined curing temperature for a period of time;

[0068] Wherein, in the preheating process of step (2) and the heating process of step (3), the position of the eccentric block 25 on the telescopic rod of the miniature servo electric push rod 24 in the vibration control box 22 is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com