Wind power blade deicing device and deicing method

A technology for wind power blades and blades, which is applied in the field of wind power blade deicing devices, and can solve problems such as the inability to guarantee the effectiveness of resistance wires, the difficulty and cost of blade manufacturing processes, and the stress concentration of wind power blades.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

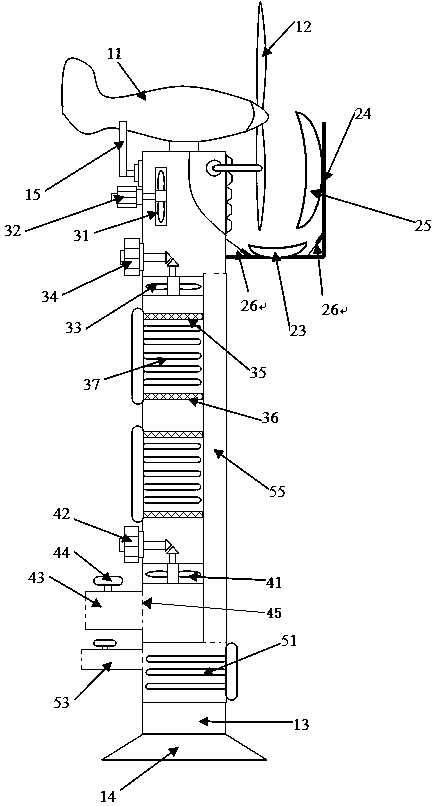

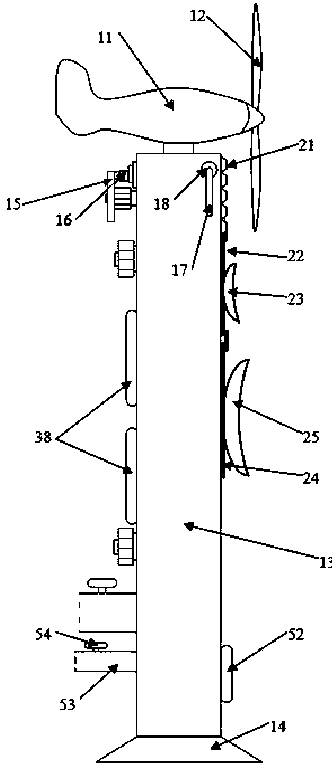

[0031] Further explanation in conjunction with accompanying drawings: as figure 1 and figure 2 The wind power blade deicing device shown includes a wind generator component, a thermal insulation control component, a hot air blowing component and a water vapor processing component. Such as figure 2 As shown, the wind turbine components include a nacelle, a wind power blade, a tower and a base, the nacelle is arranged at the top of the tower and connected to the wind power blade, and the base is arranged at the bottom of the tower for vertically fixing the tower on the ground Above, the interior of the tower is hollow.

[0032] Such as figure 1 and figure 2 As shown, the heat preservation control part includes a cabin fixing rod, a cabin fixing shaft, a blade fixing rod, a blade fixing shaft, a first rotating plate, a first concave mirror, a second rotating plate, a second concave mirror and a rotating plate telescopic rod; The fixed shaft of the nacelle is arranged on t...

Embodiment 2

[0039] The method for deicing wind turbine blades using the wind turbine blade deicing device of Embodiment 1 specifically includes the following steps:

[0040] (1) It is observed that there is icing on the outer surface of the wind turbine blades, inject a mixed liquid of pure water and ethanol through the water inlet pipe, in which the volume ratio of pure water and ethanol is 35:1, and start the water body heater, and use the water body heating rod to The mixed liquid is heated to evaporate it.

[0041] (2) Start one of the engine room fixing shafts to rotate and drive the engine room fixing rod to rotate from the head down to the head up ( figure 1 Due to the occlusion, only one of them can be displayed. In fact, when the head is turned upward, it is impossible to achieve vertical upward, because after contacting the cabin, the cabin fixing rod is inclined, and there is a certain gap between the two cabin fixing rods. angle), fix the position of the nacelle from the side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com