Flocculation washing machine and control method thereof

A technology of flocculation washing machine and control method, which is applied to the control device of washing machine, other washing machines, water treatment parameter control and other directions, can solve the problems of a large amount of flocs remaining, the filtering efficiency is reduced, the filter element is blocked, etc. The effect of improving detection accuracy and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

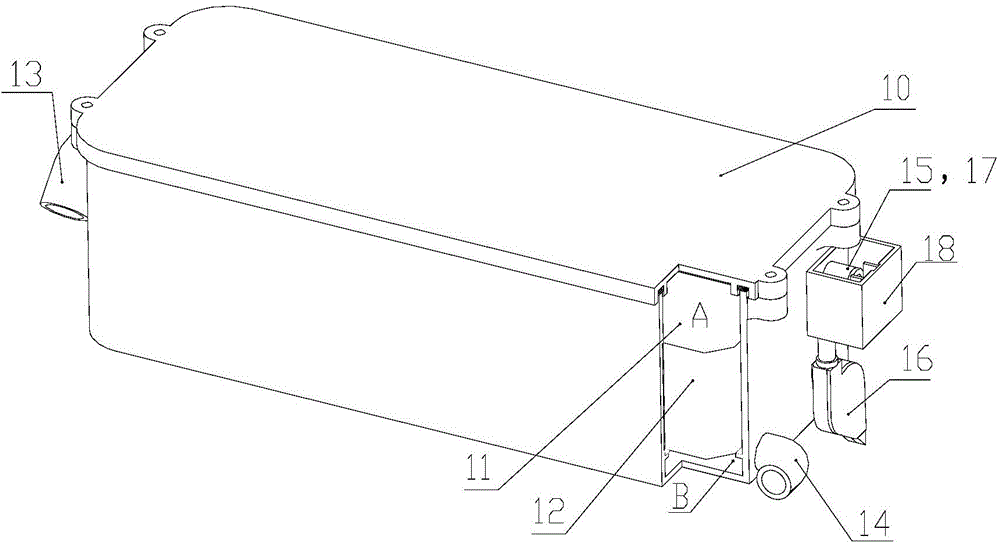

[0039] Such as figure 2As shown, in this embodiment, the overflow port 15 of the filter device 10 communicates with the flocculation bucket 20 through the overflow pipe 30 , so that the overflow water at the filter device 10 flows back into the flocculation bucket 20 from the overflow pipe 30 . The overflow pipe 30 is provided with a first flow sensor 16 for detecting overflow flow velocity.

[0040] In this embodiment, comparing the detected value of the first flow sensor 16 with the preset set value V1 in the system has the following conditions:

[0041] Situation 1. When the detection value of the overflow flow rate of the filter device is equal to 0, it is judged that the filter device is not blocked, and the filter device is working normally;

[0042] Situation 2: When the detection value of the overflow flow rate of the filter device is greater than 0 and less than the set value V1, it is judged that the filter device is slightly blocked, the flow rate of the water in ...

Embodiment 2

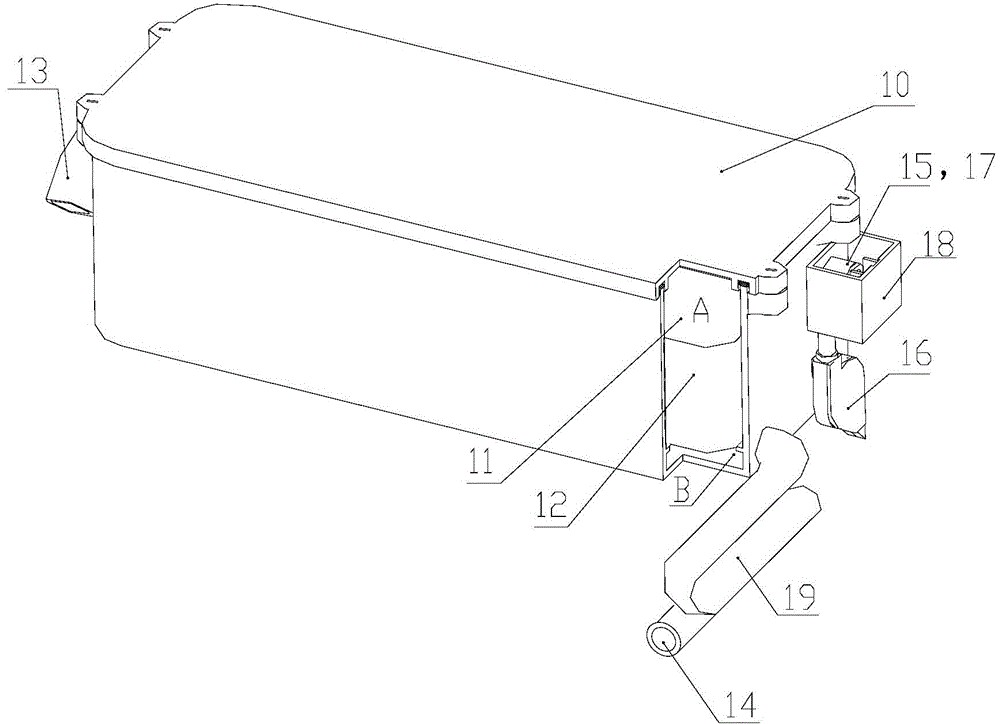

[0049] Such as image 3 As shown, in this embodiment, the water outlet 14 of the filter device 10 is provided with a second flow sensor 19 for detecting the water flow velocity.

[0050] In this embodiment, comparing the detection value of the second flow sensor 19 with the preset set value V2 in the system is as follows:

[0051] Situation 11. When the outlet flow rate of the filter device is greater than the set value V2, it is judged that the filter device is not blocked, and the filter device works normally;

[0052] Situation 12: Within a certain period of time t, the detected value of the water outlet flow rate of the filter device is always lower than the set value V2, and it is judged that the filter device is blocked.

[0053] Preferably, in this embodiment, in case 12, it is judged that the filter device is slightly clogged, the flow rate of water entering the filter device decreases, and a prompt signal is sent out that the filter device needs to clean the filter e...

Embodiment 3

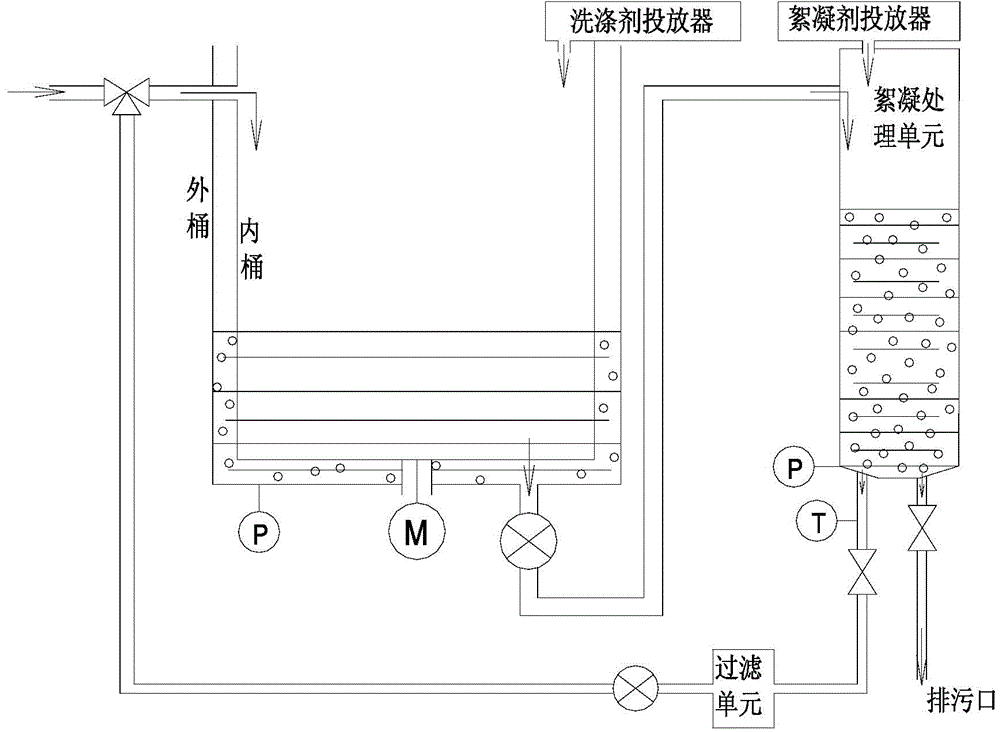

[0057] Such as figure 1 and Figure 4 As shown, in this embodiment, the flocculation bucket 20 is provided with a water level sensor 21 for detecting the height of the water level inside it.

[0058] In this embodiment, the detection value of the water level sensor 21 is compared with the preset set value h in the system as follows:

[0059] Situation 21. When the outlet flow rate of the filter device is greater than the set value V2, it is judged that the filter device is not blocked, and the filter device is working normally;

[0060] Situation 22. Within a certain period of time t, the water level drop of the flocculation water in the flocculation bucket is less than the set value h, and it is judged that the filter device is blocked.

[0061] Preferably, in this embodiment, in case 22, it is judged that the filter device is severely blocked, the water supply to the filter device is stopped, and a prompt signal is issued to indicate that the filter element needs to be rep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com