A prefabricated ground connection wall with angle steel joint limit and its construction method

A technology of ground connection wall and angle steel, which is applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problem that the installation position and installation effect of prefabricated ground connection wall are difficult to control, the wall connection effect is difficult to be guaranteed, and the wall surface The flatness is not easy to control and other problems, to achieve the effect of reducing the probability of water and mud inrush accidents, reliable wall flatness, and a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

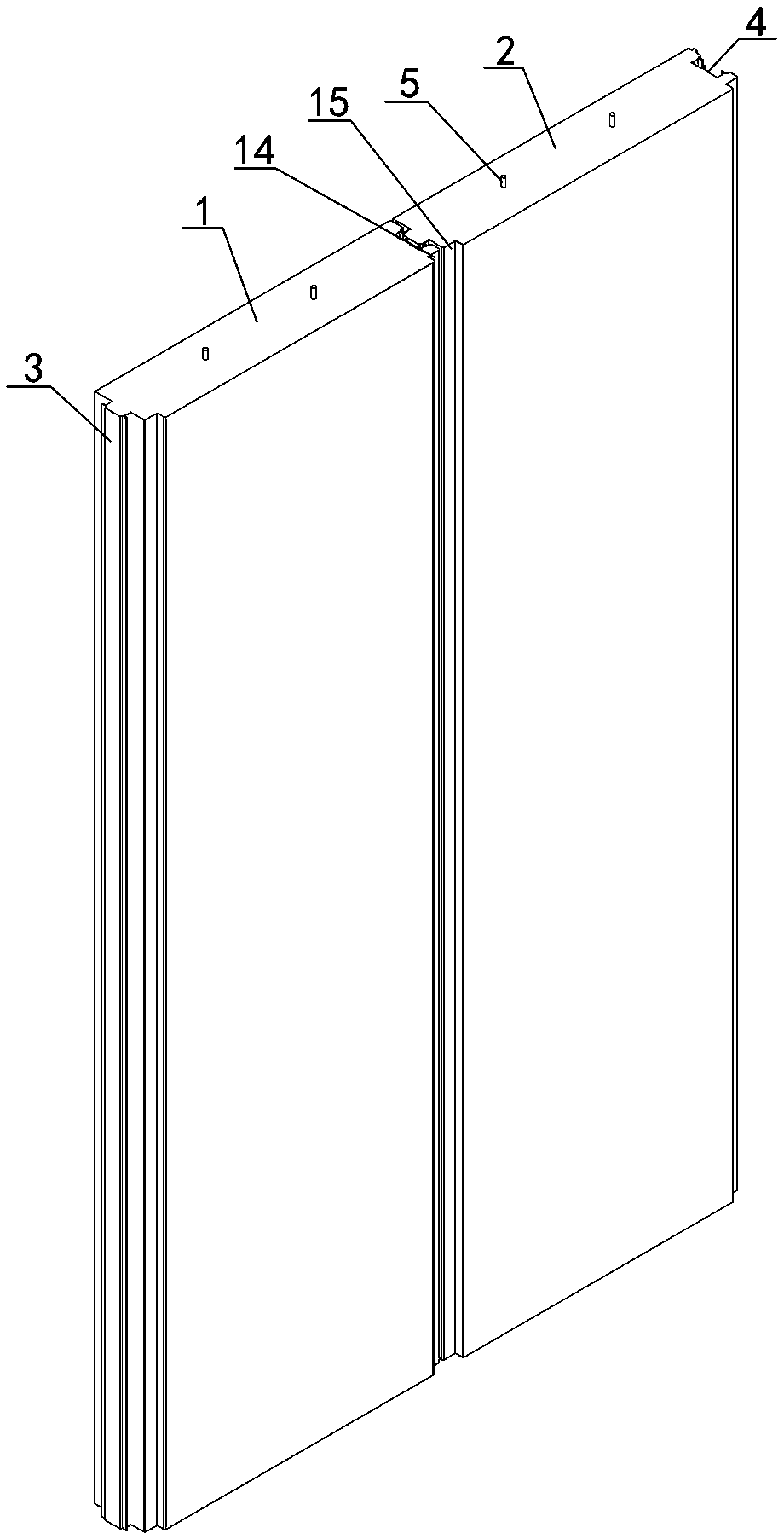

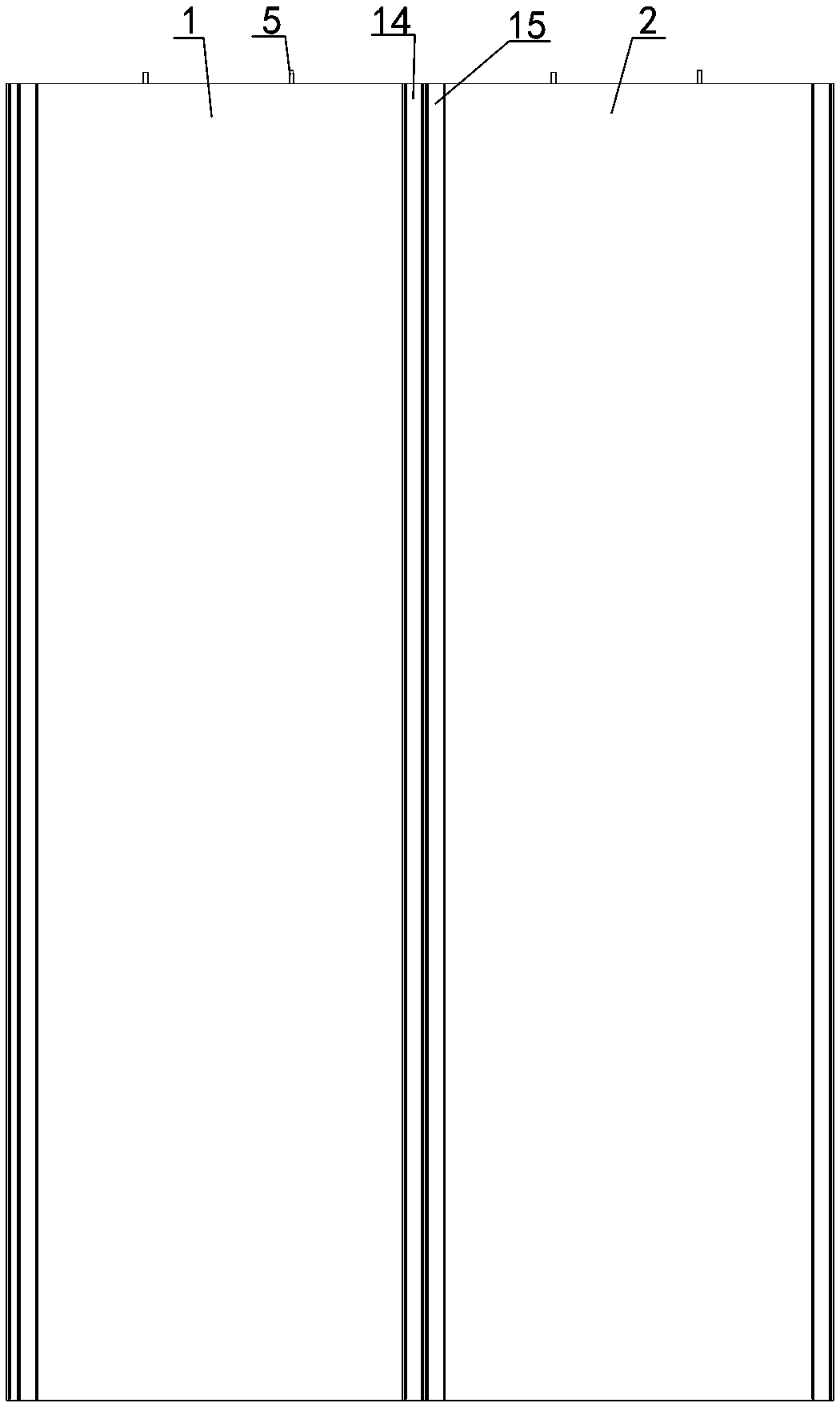

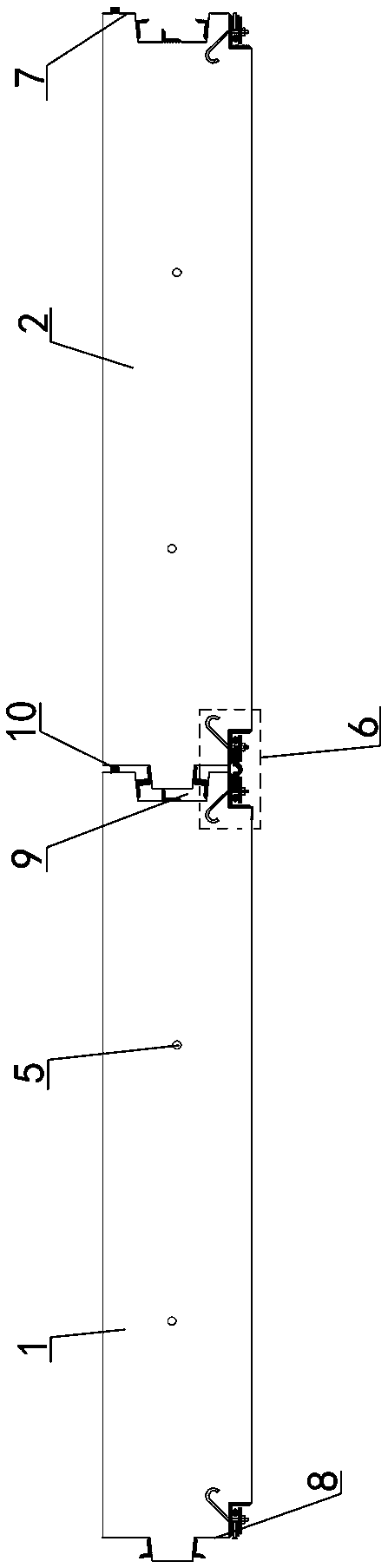

[0054] Examples see Figure 1-4 As shown, a prefabricated ground connection wall with angle steel joint limit, the prefabricated ground connection wall is spliced from the inserted wall panel 1 and the wall panel 2 to be inserted, and the middle part of the right end surface of each wall panel is set There are grooves 4 that are long up and down and combined positive surfaces 7 on both sides, and the left end surface of each wall is provided with a protruding head 3 that is long up and down, corresponding to the groove 4 and the positive surface that is combined, and a combined negative surface 8. The surface of the groove is composed of a groove bottom surface 4.1 and two groove sides 4.2, and the surface of the convex head is composed of a convex top surface 3.1 and two convex sides 3.2. There is an angle steel limit system between the wall panels. The angle steel limit system is located in the joint grouting cavity 15, including the left and right limit angle steels and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com