Deep mixing pile machine

A technology of deep mixing piles and mixing shafts, which is applied in the direction of sheet pile walls, buildings, and foundation structure engineering, and can solve the problems of increasing the amount and cost of cement slurry, poor embedding effect of support piles, and uneven cement slurry. problems, to achieve the effect of facilitating the spread of slurry, shortening the construction period, and improving the uniformity and compactness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

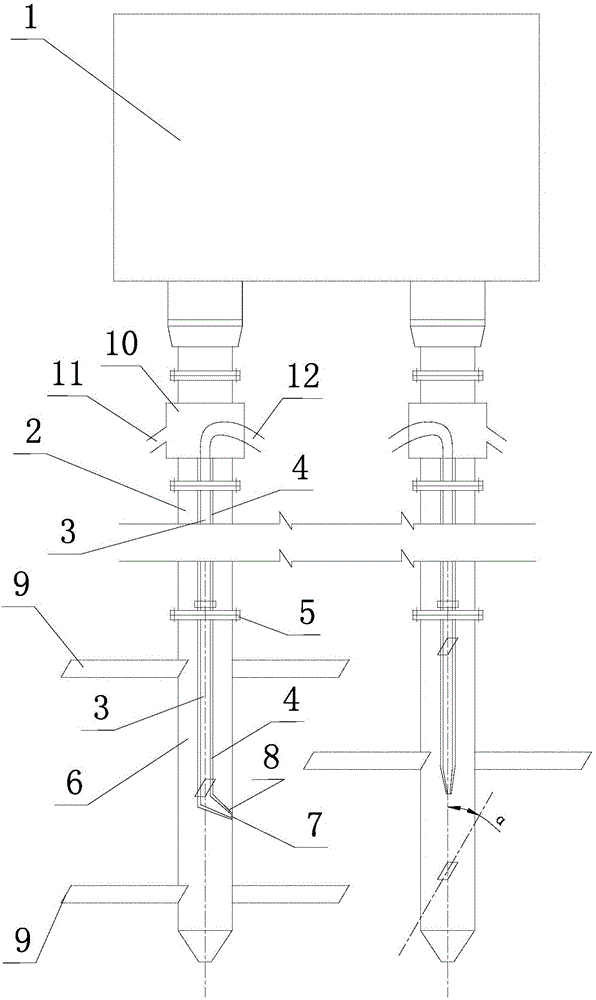

[0015] Such as figure 1 Shown, the deep layer stirring pile driver of the present invention, it comprises pile frame, power head 1, hollow stirring shaft 2, slurry delivery pipe 3, slurry delivery pump, slurry mixer, air delivery pipe 4, air compressor, spray nozzle 7 and Air nozzle 8.

[0016] The power head 1 is installed on the pile frame, the stirring shaft 2 is mounted on the power head 1 and a hollow butt joint 10 is arranged between the stirring shaft 2 and the power head 1 . The lower end of the stirring shaft 2 is fixed with a stirring head 6 through a flange plate 5 . The slurry nozzle 7 and the air nozzle 8 are located in the cavity of the mixing head 6 and the nozzles of the slurry nozzle 7 and the air nozzle 8 all extend out of the mixing head 6 . The air nozzle 8 is sleeved on the outside of the spray nozzle 7 .

[0017] The s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com