Multi-cutter-head diameter-variable milling cutter

A technology of milling head and chisel, which is applied in the direction of earth mover/excavator, construction, etc., to achieve the effect of increasing milling speed, wide operation range and high operation quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

[0016] The present invention will be described in detail below with reference to the accompanying drawings and examples.

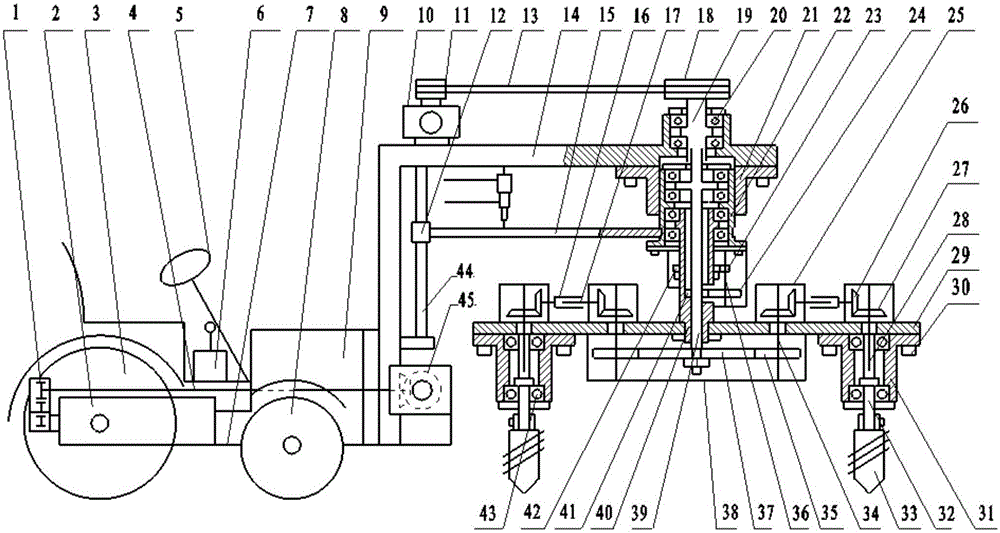

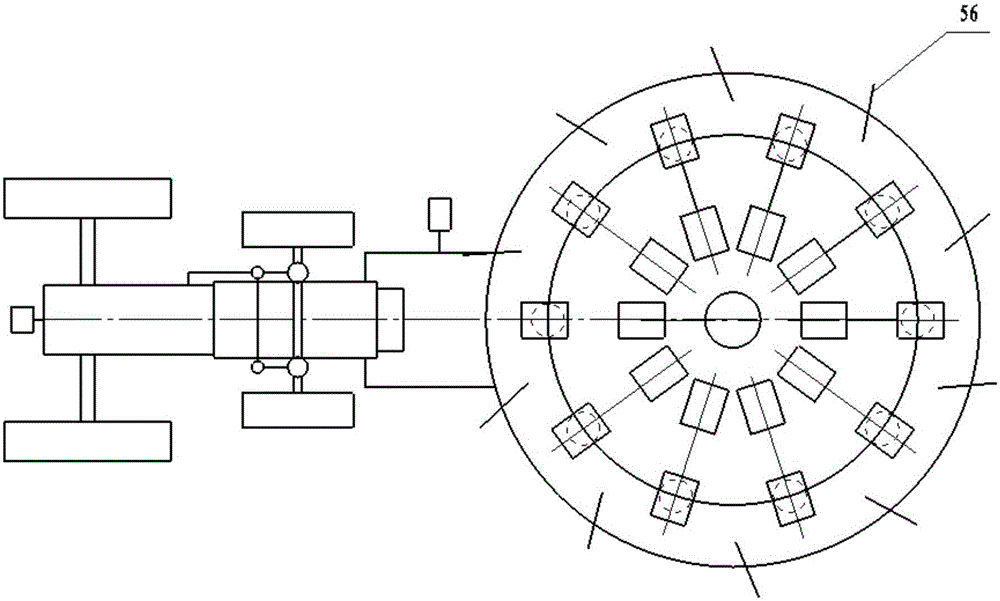

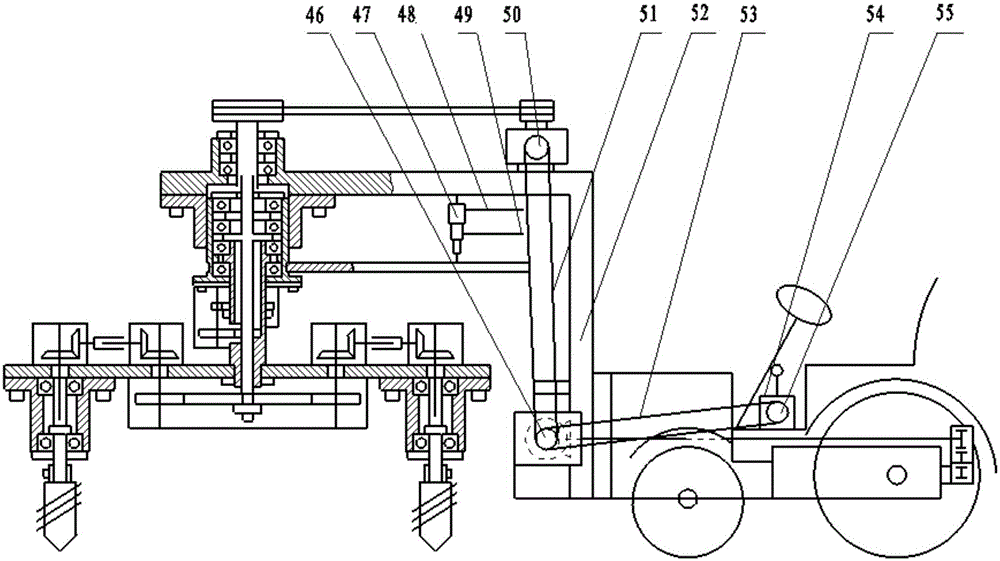

[0017]According to the present invention, a multi-milling-head variable-diameter milling machine is composed of a rear gearbox 1, a main engine gearbox 2, a driving wheel 3, a main drive shaft 4, a main engine control system 5, a working device control system 6, and a main frame 7. Guide wheel 8, engine 9, working device gearbox 10, working device main pulley 11, lifting beam guide column cover 12, main driving belt 13, working device beam 14, lifting beam 15, sub-transmission shaft tube 16, sub-transmission Square shaft 17, working device slave pulley 18, power transmission internal spline shaft tube 19, internal spline shaft bearing 20, main guide sleeve 21, lifting sleeve 22, main rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com