Fixing structure for integrated ultra-thin heat preservation panels and manufacturing and installing method for fixing structure

A technology for fixing structures and thermal insulation boards, which is applied in building construction, covering/lining, construction, etc., and can solve the problems of increasing building weight, difficulty in construction, and lack of a good fixing method for thin plates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

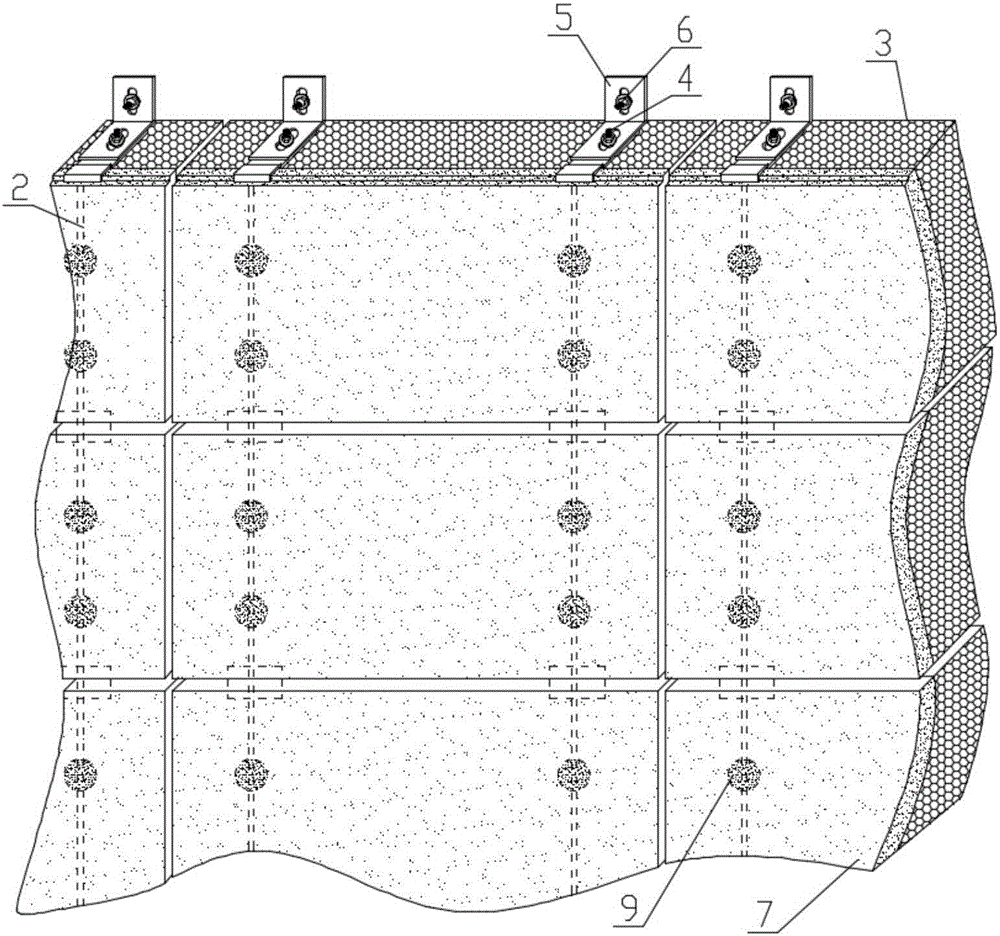

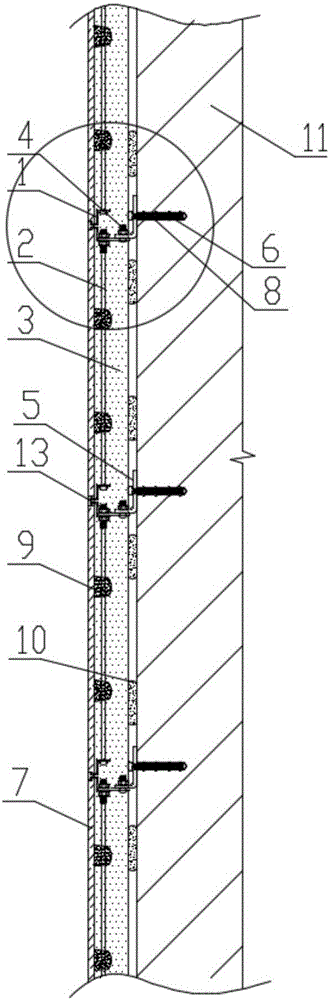

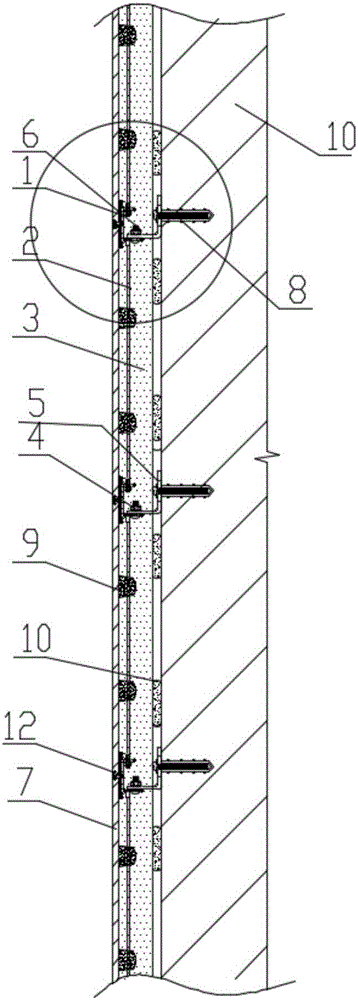

[0017] As shown in the accompanying drawings, 1 in the figure is a pendant, the pendant has two kinds of upper pendants 1-1 and 1-2, and two kinds of lower pendants 1-3 and 1-4, 2 is a steel rope or steel bar, and 3 is heat preservation Plate, 4 is positioning screw, 5 is corner code, 6 is fixing bolt, 7 is panel, 8 is expansion tube, 9 is structural rubber group (glue point), 10 is cement, 11 is main body, such as wall, 12 is Weather-resistant sealant, 13 is a connector, the thermal insulation integrated ultra-thin panel fixing structure of the present invention includes an integrated thermal insulation decorative board; the integrated thermal insulation decorative board includes a panel 7 and a thermal insulation board 3 connected Integrate, the middle of the steel rope or steel bar passes through the insulation board 3, then the lower end is connected to the lower pendant, and the upper end is connected to the upper pendant, and the middle of the steel rope or steel bar 2 pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com