Preset cable directly controlled type electronic-control layered polymer injection technique pipe and polymer injection method

A process string, direct-controlled technology, applied in earth-moving drilling, fluid extraction, measurement, etc., can solve the problems of easy blocking, instability, low deployment control efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

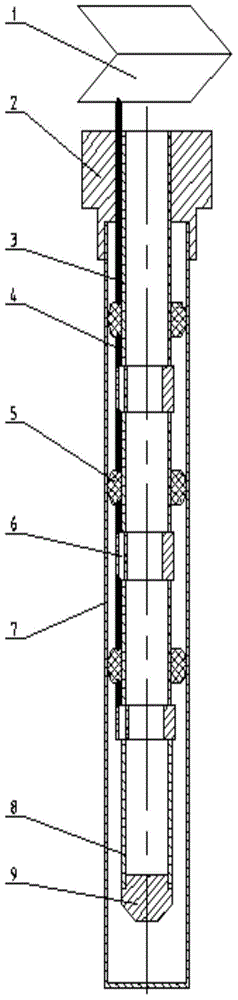

[0014] Such as figure 1 As shown, the preset cable direct-controlled electronically controlled layered polymer injection process string provided by the present invention includes a casing 7, and there is an oil pipe 3 inside the casing 7, and the annular space between the casing 7 and the oil pipe 3 is formed by Several cable-passing well-flushable packers 5 are separated into different layers, and steel pipe single-core cables 4 pass through the above-mentioned cable-passable well-flushable packers 5, and each layer is equipped with a flow rate direct-reading downhole Electric control polymer injector 6, the injection volume adjustment of the flow direct-reading downhole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com