Pneumatic anchor rod and anchor cable drill loader

A drilling machine and anchor cable technology, which is used in the installation of anchor rods, driving devices for drilling in wellbore, drilling equipment, etc., to achieve the effects of convenient operation, reduced labor intensity, and fast support speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

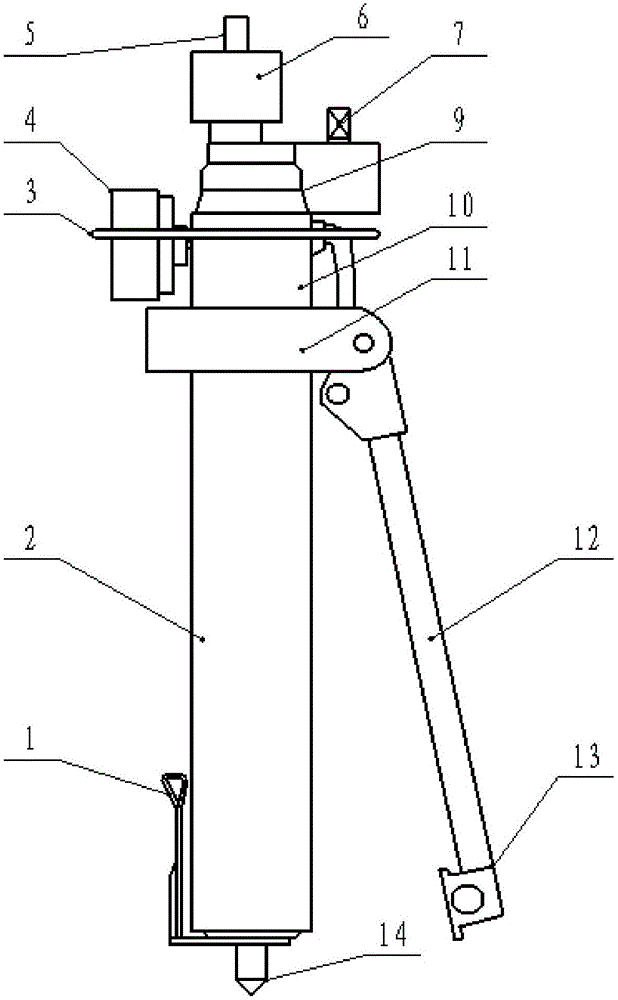

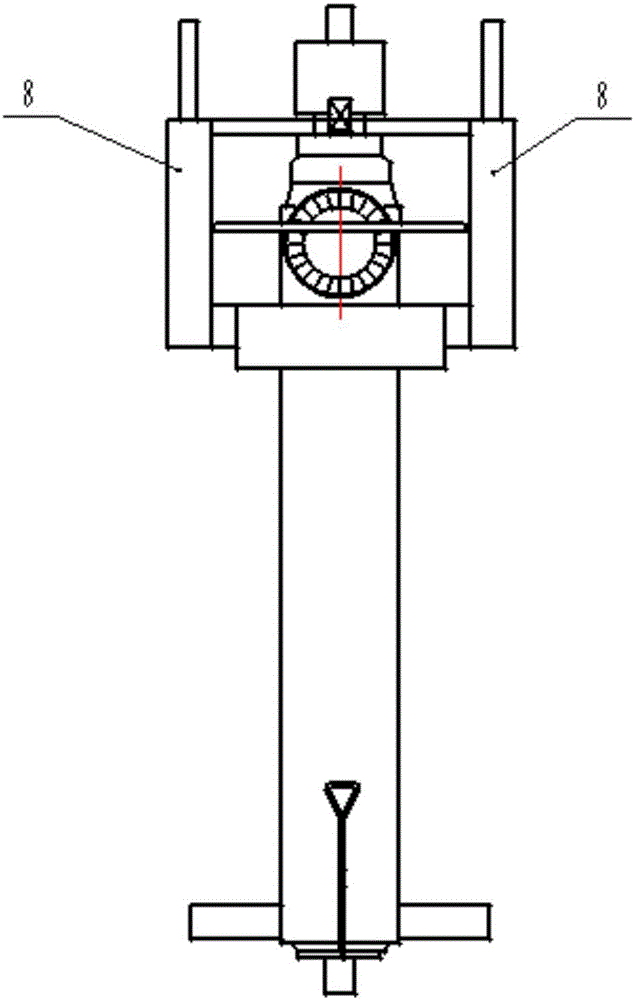

[0022] The specific embodiments of the present invention will be described in further detail below in conjunction with the drawings and embodiments. The following examples are used to illustrate the present invention, but not to limit the scope of the present invention.

[0023] Such as Figure 1-2 As shown, the present invention provides a pneumatic bolt and cable drilling machine, including a propulsion mechanism, a rotation mechanism and a manipulation control mechanism. The propulsion mechanism is a multi-stage air cylinder 2 used to advance and retract the rotation mechanism; the rotation mechanism consists of The pneumatic motor 10 compresses air to provide power, which is transmitted to the drill rod connecting shaft 5 after being decelerated by the gearbox 9 for drilling and / or the agitation of the anchor rod and the anchor cable; wherein, the rotating mechanism is also provided with a pretension The output shaft 7, the pre-tightening output shaft 7 is powered by a pneum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com