Automobile tail gas purifier

A technology for automobile exhaust and purifier, applied in chemical instruments and methods, exhaust treatment, exhaust devices, etc., can solve the problems of limited exhaust purification effect, single purification effect, complex structure, etc., to shorten production time, coating High efficiency and improved catalytic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

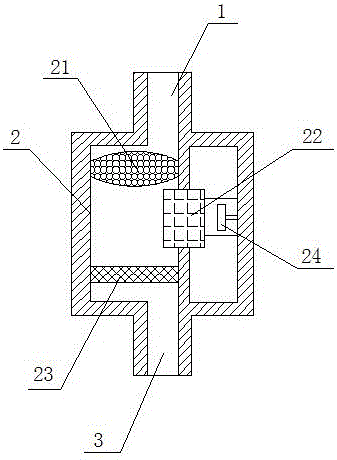

[0025] like Figure 1 to Figure 2 As shown, the present invention provides an automobile exhaust purifier, comprising: an air inlet 1 , a clean chamber 2 communicating with the air inlet 1 , and an air outlet 3 communicating with the clean chamber 2 . Automobile exhaust can enter the purification chamber 2 of the automobile exhaust purifier from the air inlet 1, and be discharged from the air outlet 3 after being purified by the purification chamber 2.

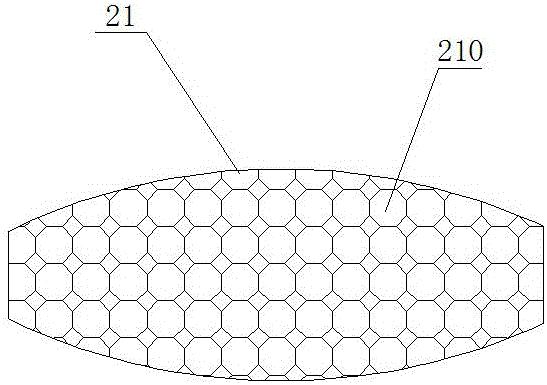

[0026] Specifically, a honeycomb aluminum block 21 is provided near the air inlet 1 inside the clean room 2, and the honeycomb aluminum block 21 has interconnected holes 210, and the walls of the holes 210 are coated with a catalyst, which can remove particulate matter in the exhaust gas. The filter is deposited in the holes 210 of the honeycomb aluminum block 21, and the catalyst covered in the holes 210 is used to catalyze and purify the exhaust gas, which increases the contact surface area between the exhaust gas and the ca...

Embodiment 2

[0028] Catalyst for automobile exhaust gas purifier, including honeycomb aluminum block carrier, pore density is 550cpsi, pore wall thickness is 3.8mil, volume is 0.85L; Pd coating is coated on the honeycomb aluminum block carrier, and the coating amount of Pd coating is 120g / L; the Rh coating is coated on the Pd coating, and the coating amount of the Rh coating is 85g / L; wherein, the Pd content in the Pd coating is 80g / ft 3 , the Rh content in the Rh coating is 15g / ft 3 .

Embodiment 3

[0030] A method for coating and processing catalysts for automobile exhaust purifiers, the steps are as follows:

[0031] ① Coating with Pd coating

[0032] 84g of ZrO 2 , 36g of Pr 6 o 11 , 7.2g La 2 o 3 , 82.8g of γ-Al 2 o 3 , 3g of Zanthoxylum glabrata and an appropriate amount of deionized water are ball milled and mixed, then 5g of palladium nitrate is added and mixed evenly to obtain coating slurry A; then coating slurry A is coated on the honeycomb aluminum block according to the coating amount of 120g / L on the carrier, and finally baked at 650°C for 6 hours to obtain a Pd coating;

[0033] ② Apply Rh coating

[0034] 76.5g of ZrO 2 , 13.5g of Y 2 o 3 , 4g of CeO 2 , 4g of La 2 o 3 , 96g of γ-Al 2 o 3 , 2g of Zanthoxylum glabrata and an appropriate amount of deionized water ball mill and mix, then add 0.5g of rhodium nitrate and mix uniformly to obtain coating slurry B; then apply coating slurry B to the coated The Pd-coated honeycomb aluminum block car...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com