Method for determining performance indexes of pressure atomizing nozzle

A determination method and technology of atomizing nozzles, applied in the direction of fuel injection device, engine test, machine/structural component test, etc., can solve the problems of poor combustion performance and large loss, achieve good combustion performance, reduce repetition and loss , the effect of shortening the R&D cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] In order to further understand the content of the invention, characteristics and effects of the present invention, the following examples are described in detail as follows:

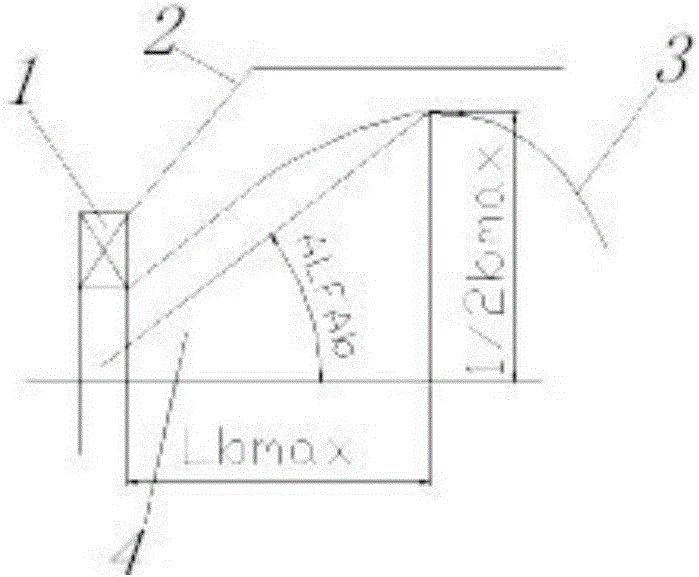

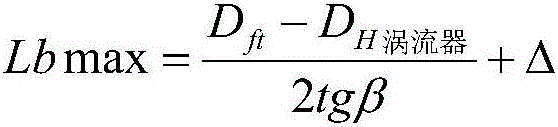

[0011] The present invention comprises the following steps:

[0012] a. Determination of the auxiliary spray cone angle of the fuel nozzle: the auxiliary spray cone angle mainly affects the lean flameout and ignition performance of the combustion chamber, and a small auxiliary spray angle is beneficial to the flameout and ignition performance of the combustion chamber, generally less than 80°. Select several nozzles with different angles in the range of 50°~80°, carry out the flameout test under the ground idle state, and select the best value through test screening.

[0013] b. Determination of the auxiliary spray cone angle of the fuel nozzle: it mainly affects the combustion efficiency of the combustion chamber and the outlet temperature field, so its size depends on the size and position of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com