Temperature monitoring device

A technology of monitoring device and supporting device, applied in the direction of measuring device, thermometer, temperature measurement in motor, etc., can solve the problems of inability to sense windings, capacitive coupling interference, high installation expenses, etc., to improve load utilization, The effect of reducing the overall size and reducing the installation space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Contact below Figure 1 to Figure 3 , the invention is described with the aid of exemplary embodiments, wherein identical structural features or functional features are indicated by identical symbols.

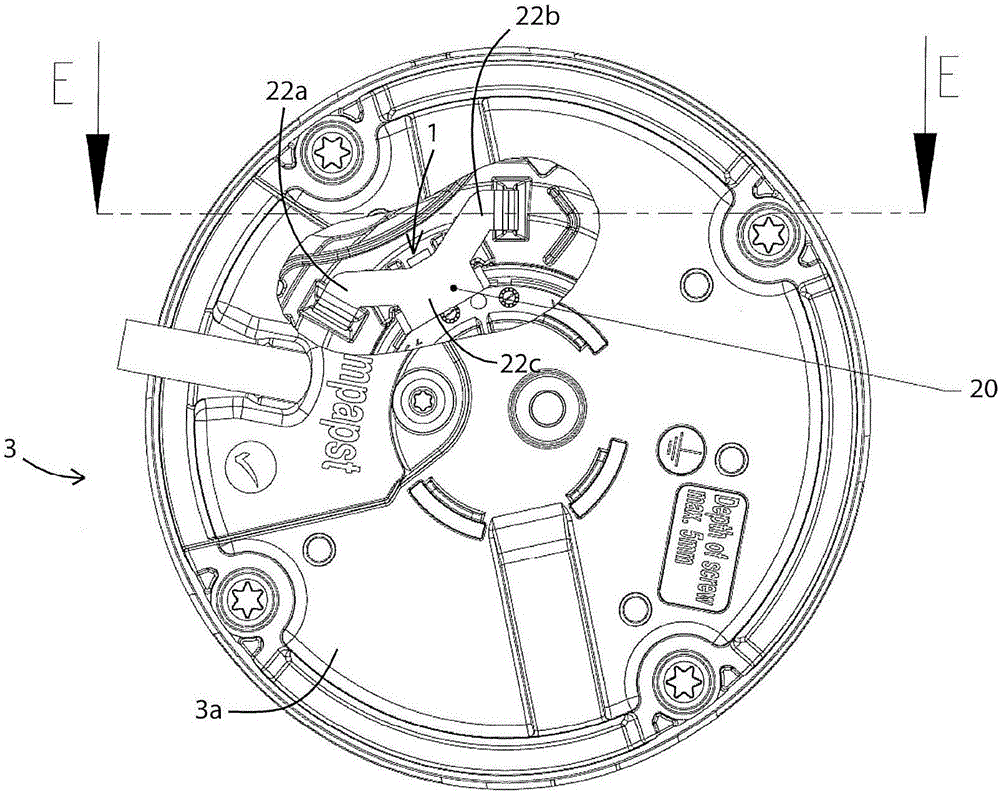

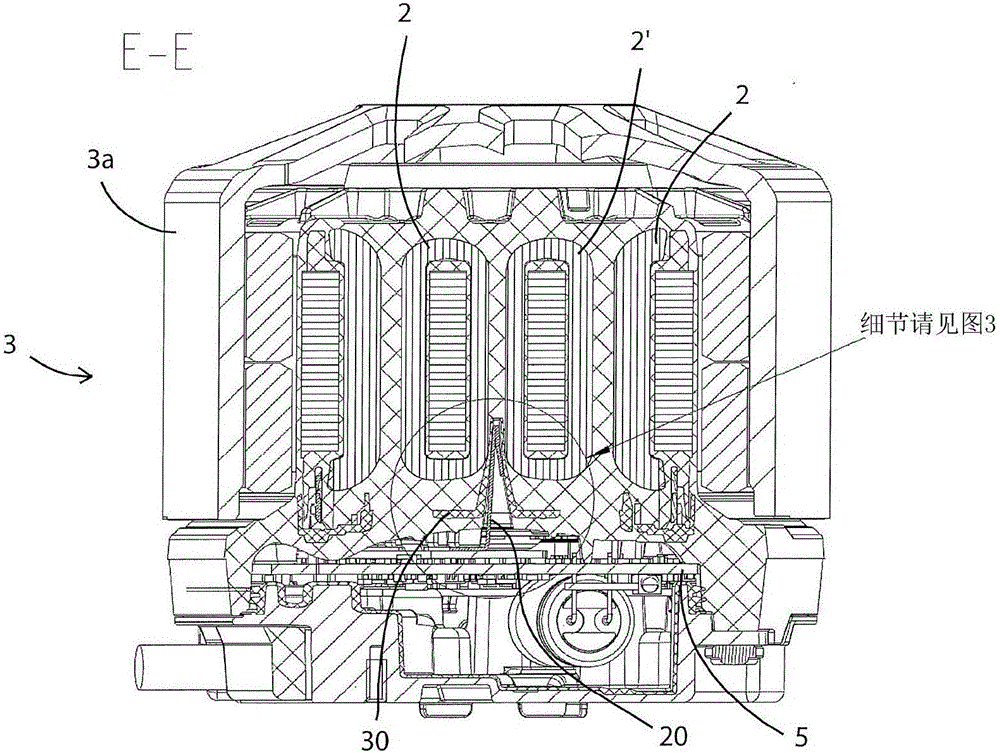

[0029] figure 1 and figure 2 An electric motor 3 is shown comprising a temperature monitoring device 1 for monitoring the windings 2, 2' of the electric motor 3.

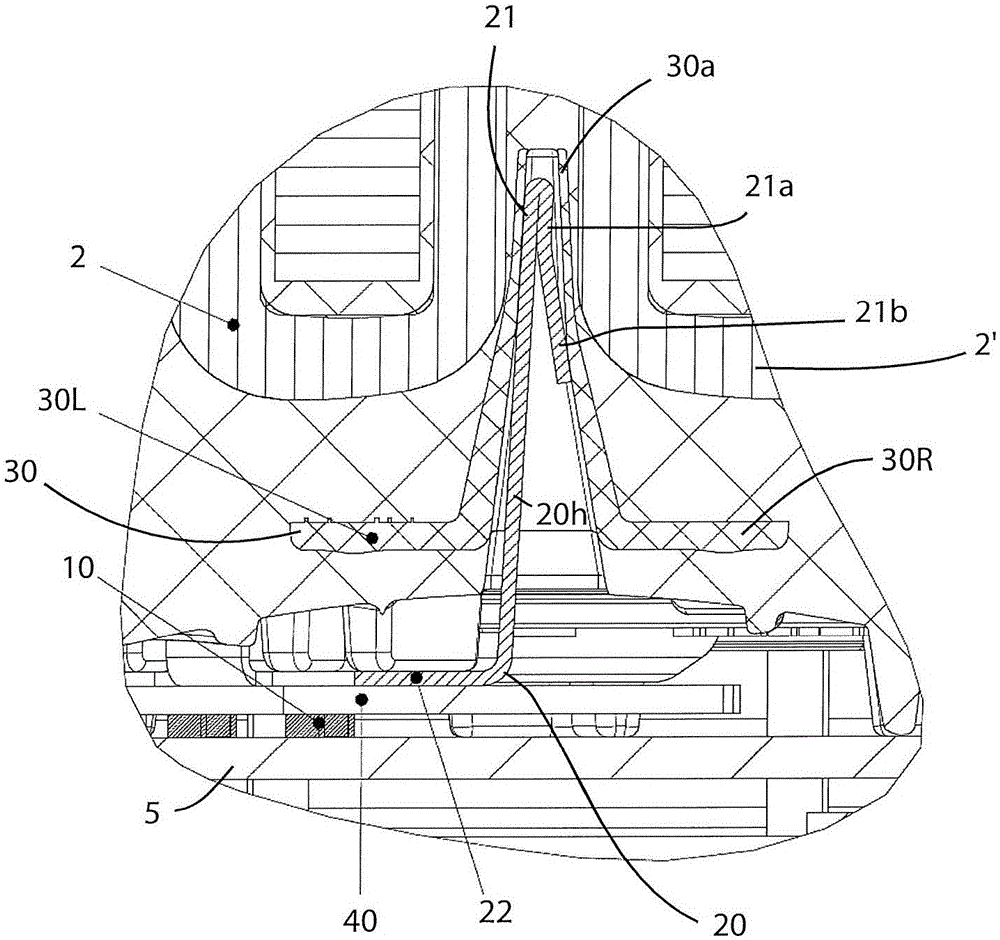

[0030] image 3 Shown are details of a temperature monitoring device 1 comprising a temperature sensor 10 spaced apart from the windings 2, 2' of the motor 3 and a heat conduction assembly 20, wherein the heat conduction assembly 20 is connected from it for thermal coupling and heat conduction to A first component part 21 , in which the windings 2 , 2 ′ are in contact or adjacent, extends to a second component part 22 , which is in contact with or adjacent to the temperature sensor 10 for thermal coupling and heat conduction.

[0031] figure 1 A view from below of the electric motor 3 is shown, wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com