Composite material spring and manufacturing method thereof

A composite material and manufacturing method technology, applied in the direction of high internal friction springs, etc., can solve the problems of heavy self-weight, poor corrosion resistance of metal springs, influence of use time, etc., to reduce weight, improve load utilization, excellent toughness and The effect of resilience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

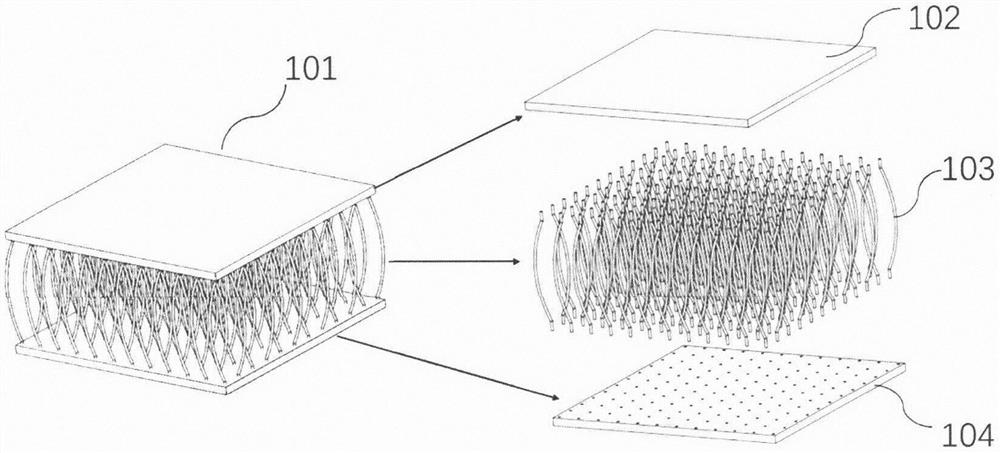

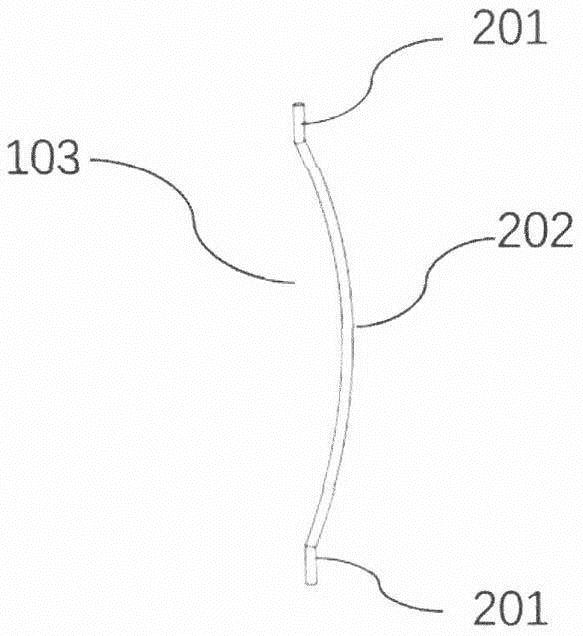

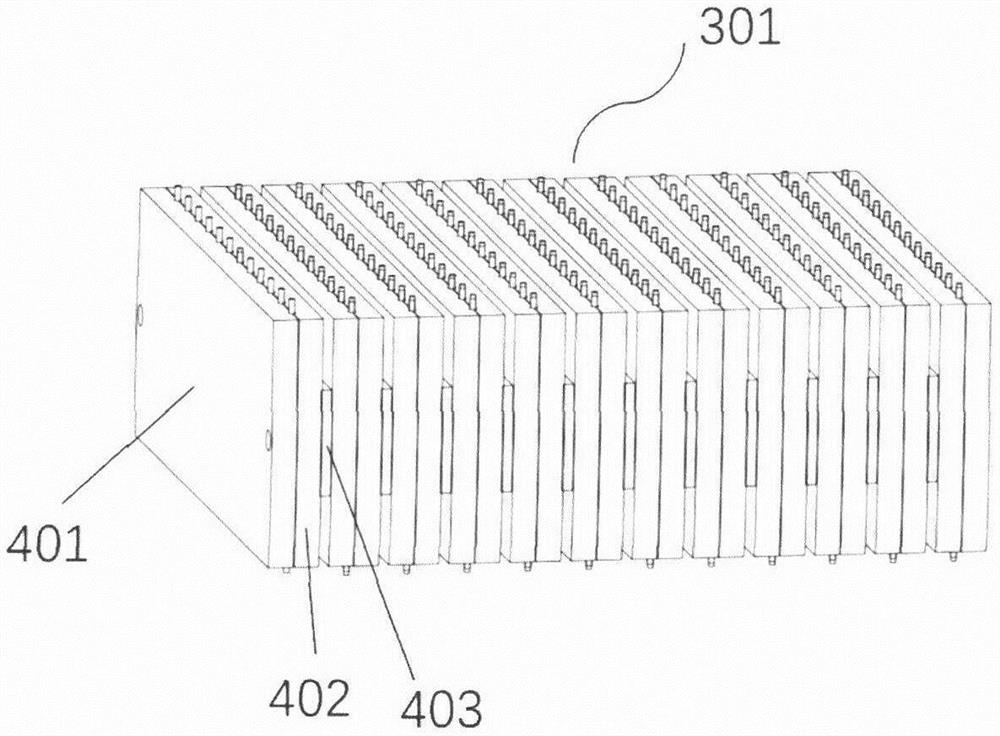

[0033] The prefabricated part of the first embodiment of the present invention is a composite material rectangular spring 101. The part 101 is divided into three parts: an upper panel 102, a lower panel 104, and a middle spring wire 103. The upper and lower panels 102, 104 have a size of 80× 80mm, thickness 1.5mm. Spring wire 103 total length is 38mm, and its up and down straight section 201 is long 2mm, and middle part curved section 202 is long 34mm, and spring wire 103 section is circular, and its diameter is 0.8mm, and the spacing between spring wire 103 and spring wire 103 is 7mm. The rectangular spring 101 in this embodiment has 12 rows of spring wires 103 in total, and there are 12 in one row. The odd-numbered row of spring wires 103 are uniformly bent to the right, and the even-numbered row of spring wires 103 are uniformly bent to the left. Th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com