Quick estimation method for ultimate stage of stacked triple-base propellants

A technology of propellant and stabilizer, which is used in chemical analysis, measuring device, instrument, etc. by titration method, can solve the problems of uneven distribution of stabilizer content, time-consuming bromide, large amount of aging samples, etc. and proportioning problems, solving the effect of uneven distribution and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0081] The typical three-base propellant SGF-1 is used as a representative for illustration.

[0082] (1) Preparation of near-infrared modeling samples with effective content of No. Ⅱ neutralizer by thermal accelerated aging method

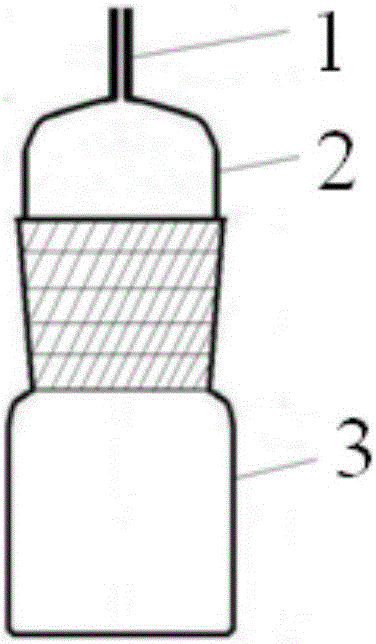

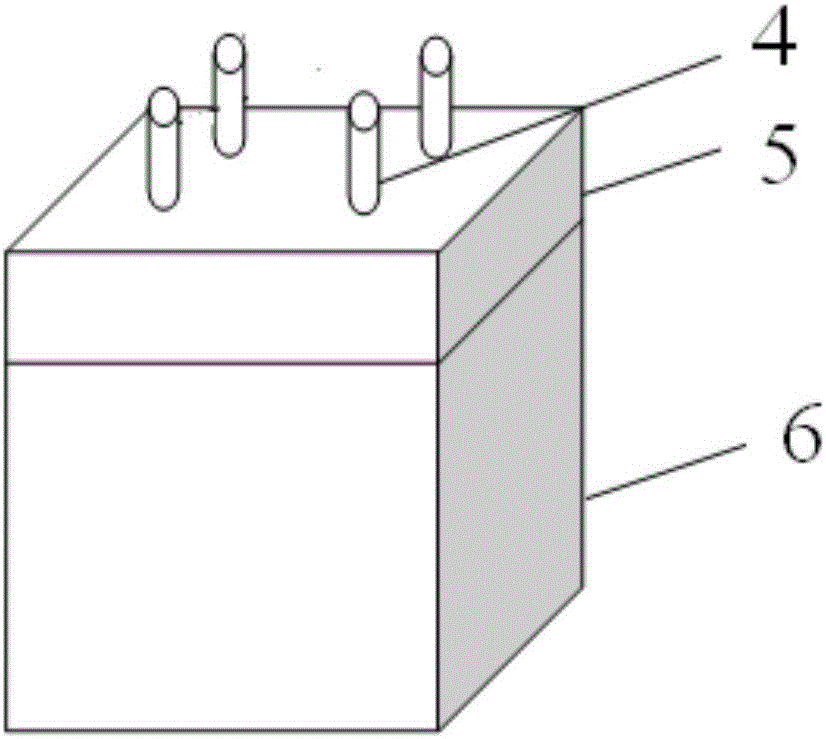

[0083] A typical three-base propellant SGF-1 is packed into a capillary exhaust tube ground-mouth reducing bottle (Φ=4cm, H=8cm) (semi-closed condition, figure 1 ) at 95°C for thermally accelerated aging, sampling every 4 hours, preparing three-base propellant samples with different stabilizer contents, and collecting 60 SGF-1 aging samples, 29 of which (numbered 1-29) were used as internal calibration sets , perform linear fitting and internal cross-validation, and 31 samples are used as an external validation set (numbered 30-60) for external validation.

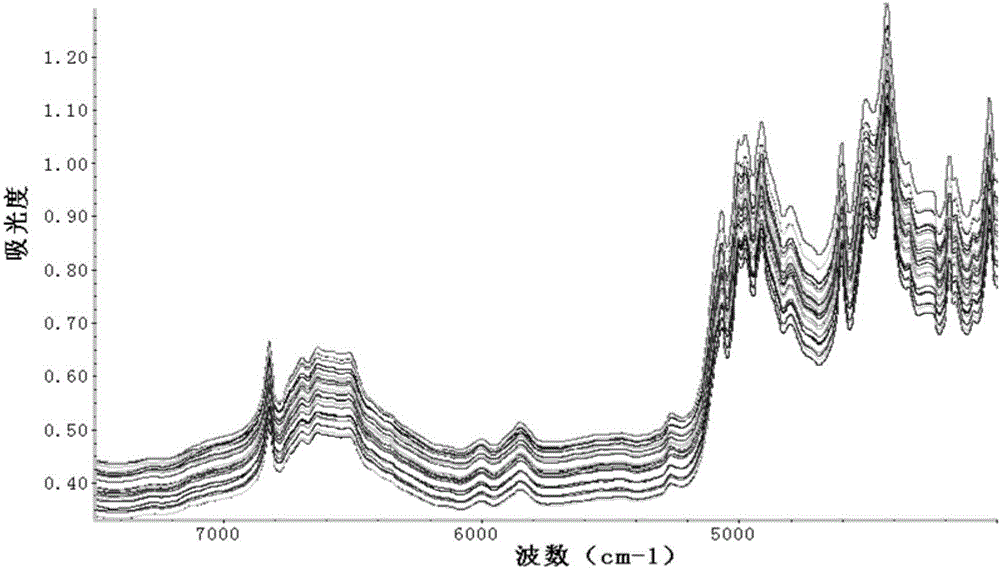

[0084] (2) Near-infrared quantitative model of the effective content of No. Ⅱ medium-dosing agent

[0085] ① The devices used include Thermo Fisher Scientific near-infrared spectrometer Anta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com