Power station boiler heating surface SA210C steel material state evaluation method

A SA210C, state assessment technology, applied in material inspection products, testing metals, etc., can solve problems such as being too sensitive to stress, inaccurate extrapolated data, and long time, to improve timeliness, avoid repeated high-temperature tests, improve The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

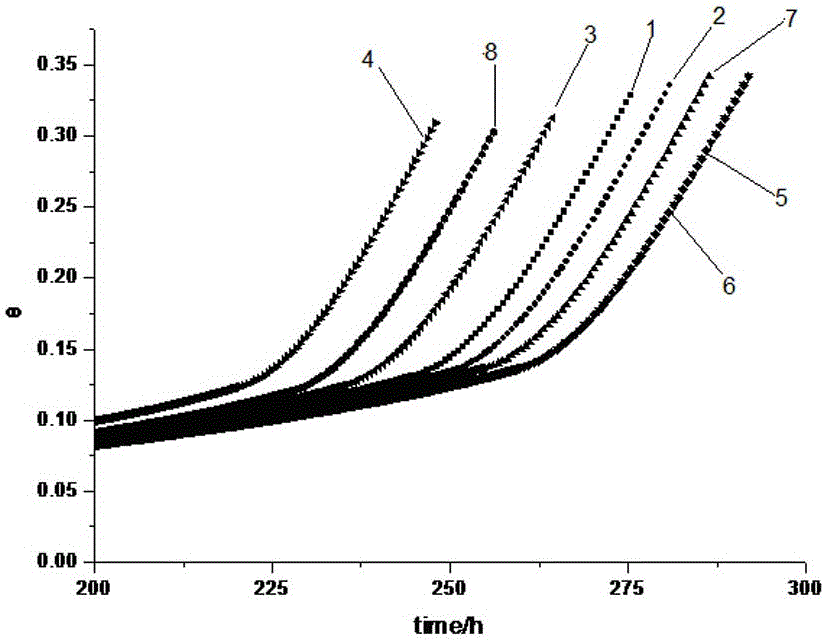

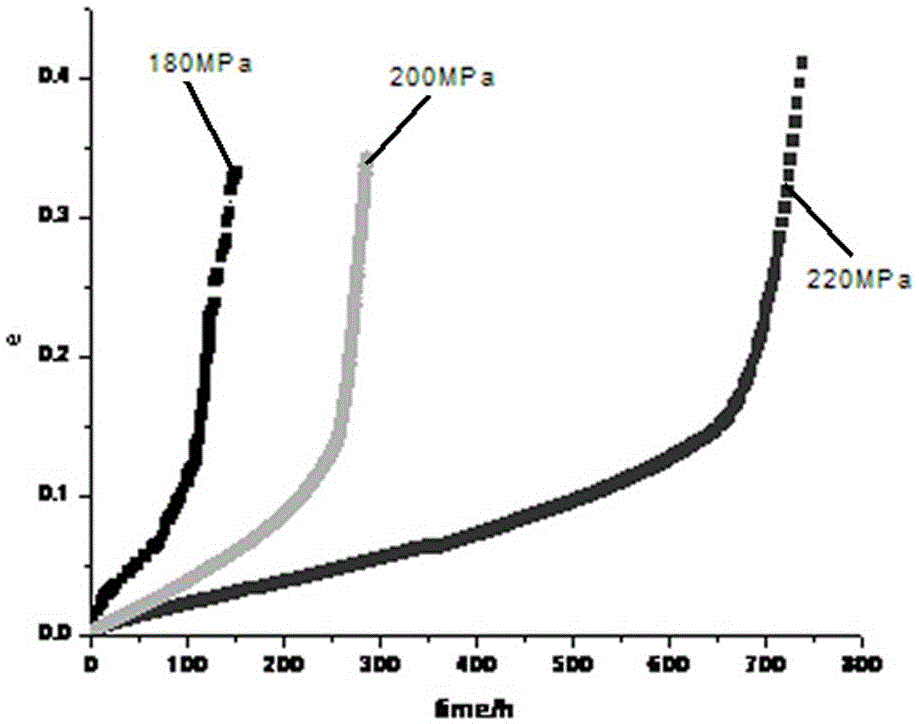

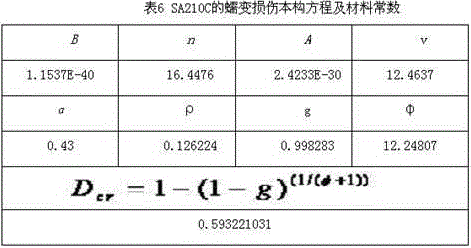

[0025] With the prolongation of operation time, the metallographic structure of SA210C on the heating surface of the utility boiler continues to age, and the mechanical properties at room temperature continue to decline. In order to study the normal temperature physical and chemical properties and the characteristic parameters and range of high temperature creep data of SA210C heating surface tubes with 2-3 pearlite spheroidization, 8 groups of samples were selected, and the test results of their normal temperature physical and chemical properties are shown in Table 1-3.

[0026] The chemical composition analysis results of the heating surface are shown in Table 1:

[0027] .

[0028] The metallographic analysis results of the heating surface are shown in Table 2:

[0029] Sample No 1 2 3 4 5 6 7 8 Nodularization level 3 2 2 2 2 3 3 3 grain size 6.0 7.0 6.0 6.0 6.0 7.0 7.0 6.0

[0030] The mechanical performance results of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com